Stable phytosterol nanometer emulsion compounded by soy protein-stevioside, and preparation method and application thereof

A technology of steviol glycosides and phytosterols is used in the preparation of phytosterol nanoemulsions and in the field of phytosterol-rich nanoemulsions, which can solve the limitations of wide application of water-based emulsions, demulsification, flocculation, stratification, and oxidative deterioration of powder products, etc. problems, to achieve good storage stability, uniform particles, and improve water solubility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (1) Soybean protein isolate was dissolved in 10mM phosphate buffer (pH7.0), stirred at room temperature for 2h, left overnight, heated in a water bath at 95°C for 30min, and cooled immediately to obtain a 1wt% soybean protein isolate solution; steviol glycoside was dissolved In 10 mM phosphate buffer (pH7.0), stir at room temperature for 1 h, adjust the pH to 7.0-7.1, and obtain a 2 wt % steviol glycoside solution.

[0055] (2) Mix the above-mentioned soybean protein isolate solution and steviol glycoside solution to obtain the aqueous phase of the composite stable system, wherein the soybean protein solution accounts for 0.5 wt% of the composite solution, and the steviol glycoside solution accounts for 1 wt% of the composite solution.

[0056] (3) adding phytosterols into sunflower oil, dispersing and dissolving at 90-99° C. to obtain an oil phase containing 10 wt % phytosterols.

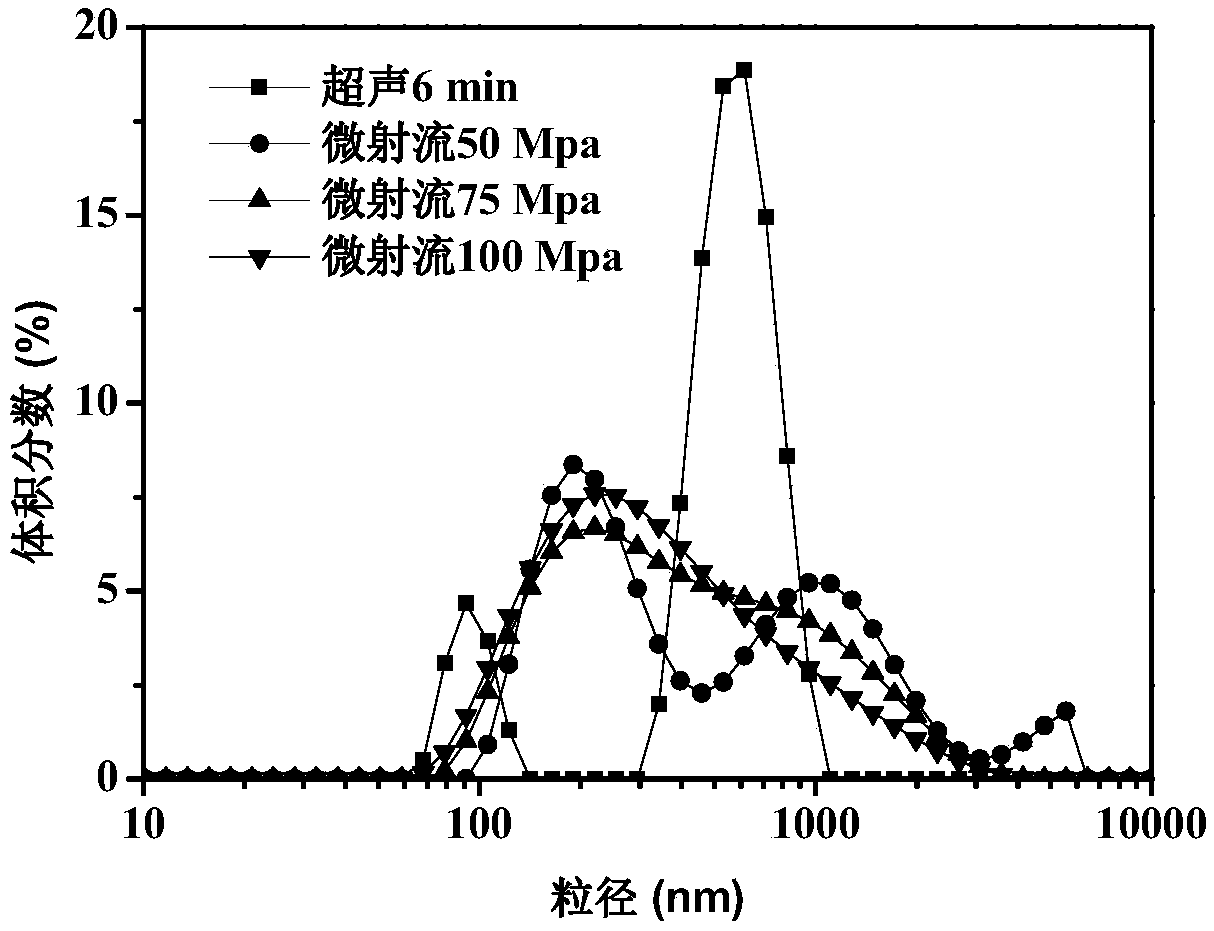

[0057] (4) According to the mass ratio of oil phase: water phase = 1:9, the oil phase di...

Embodiment 2

[0064]Soybean protein isolate was dissolved in 10mM phosphate buffer (pH7.0), stirred at room temperature for 1.5h, left overnight, heated in a water bath at 95°C for 30min, and immediately cooled to obtain a 4wt% soybean protein isolate solution;

[0065] Steviol glycosides were dissolved in 10 mM phosphate buffer (pH 7.0), stirred at room temperature for 1 h, and the pH was adjusted to 7.0-7.1 to obtain a 4 wt% steviol glycoside solution.

[0066] The water phase (mass percentage) was prepared according to the ratio in Table 1.

[0067] Table 1

[0068]

[0069] The phytosterol is added into the sunflower oil, dispersed and dissolved at 90-99° C. to obtain an oil phase containing 10 wt % phytosterol.

[0070] Add the oil phase dissolved in phytosterol into the water phase according to the mass ratio of oil phase: water phase = 1:9. After pretreatment with a homogenizer at 20,000 rpm for 1 min, use high-pressure micro-jet treatment with a pressure of 100 MPa. Three times...

Embodiment 3

[0077] Soybean protein isolate was dissolved in 10mM phosphate buffer (pH7.0), stirred at room temperature for 2.5h, left overnight, heated in a water bath at 95°C for 30min, and immediately cooled to obtain a 2wt% soy protein isolate solution;

[0078] Steviol glycosides were dissolved in 10 mM phosphate buffer (pH 7.0), stirred at room temperature for 1.5 h, and the pH was adjusted to 7.0-7.1 to obtain a 2 wt % steviol glycoside solution.

[0079] Mix the above soybean protein isolate solution and steviol glycoside solution to prepare the emulsion water phase, the soybean protein isolate solution accounts for 0.5wt% of the water phase, and the steviol glycoside solution accounts for 1wt% of the water phase. Three aqueous phases were prepared under the same operation and the same environment.

[0080] Add phytosterols to three parts of sunflower oil, all dispersed and dissolved at 98° C. to obtain oil phases containing 0wt%, 1wt% and 1.5wt% phytosterols respectively.

[0081...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com