Modified lithium ion battery cathode material, preparation method thereof, and lithium ion battery comprising same

A technology for lithium ion batteries and positive electrode materials, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable normal deintercalation of lithium ions and affecting the rate performance of finished batteries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

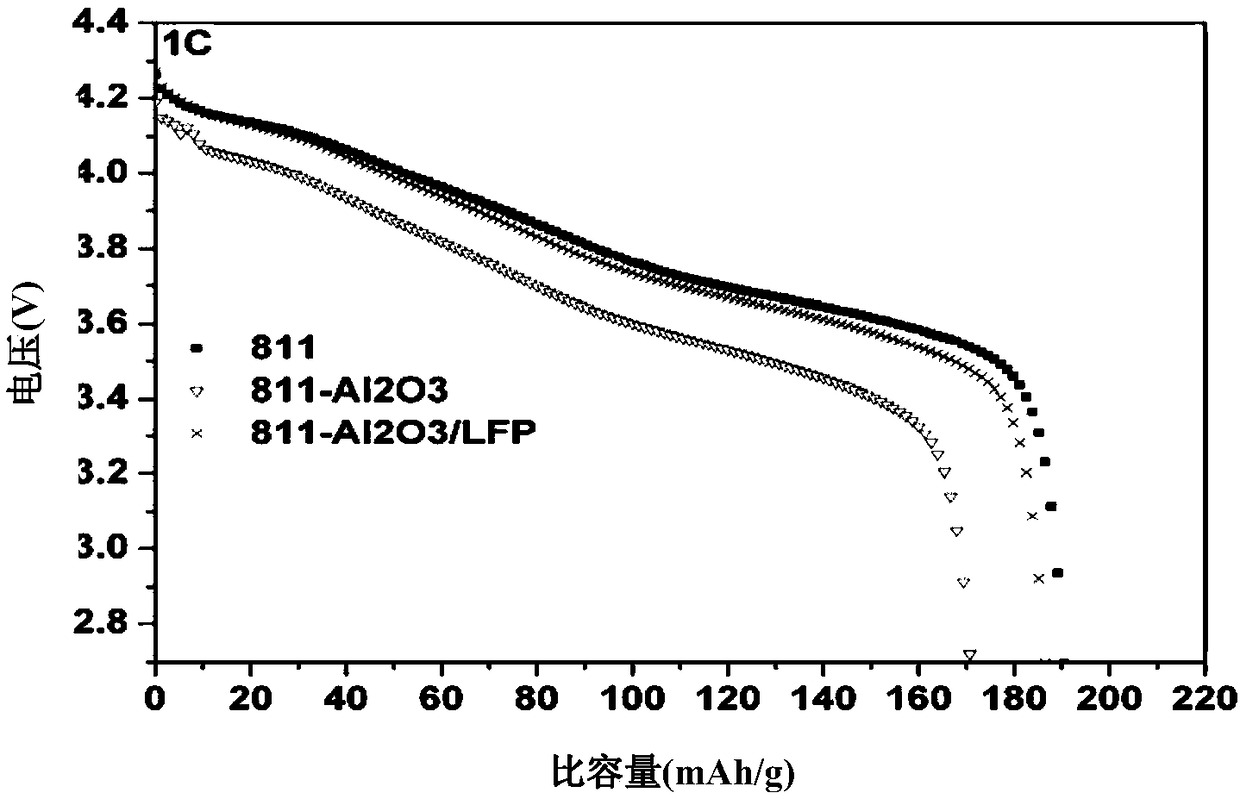

[0028] Example 1: NCM811 / Al 2 o 3 / LFP cathode material

[0029] In this embodiment, NCM811 (nickel-cobalt-manganese 811) is used as the positive electrode substrate, and Al 2 o 3 As a high-temperature stable material, LFP (lithium iron phosphate) is used as the positive electrode active material to prepare the positive electrode material NCM811 / Al for lithium-ion batteries 2 o 3 / LFP.

[0030] Step 1: Preparation of Conventional Positive Electrode

[0031] The electrode slurry raw materials are provided according to the weight ratio of NCM811: PVDF (polyvinylidene fluoride): conductive agent = 90:5:5. An NMP (N-methylpyrrolidone) solvent was added so that the solid content would be 60% by weight. Stir and mix in a ball mill to form a slurry. Then, evenly coat the slurry on the surface of the aluminum foil and roll it to make the compaction density 3.2-3.5g / cm 3 . Then, it was vacuum-dried at 110° C. overnight to make NCM811 positive electrode sheet.

[0032] Step 2...

Embodiment 2

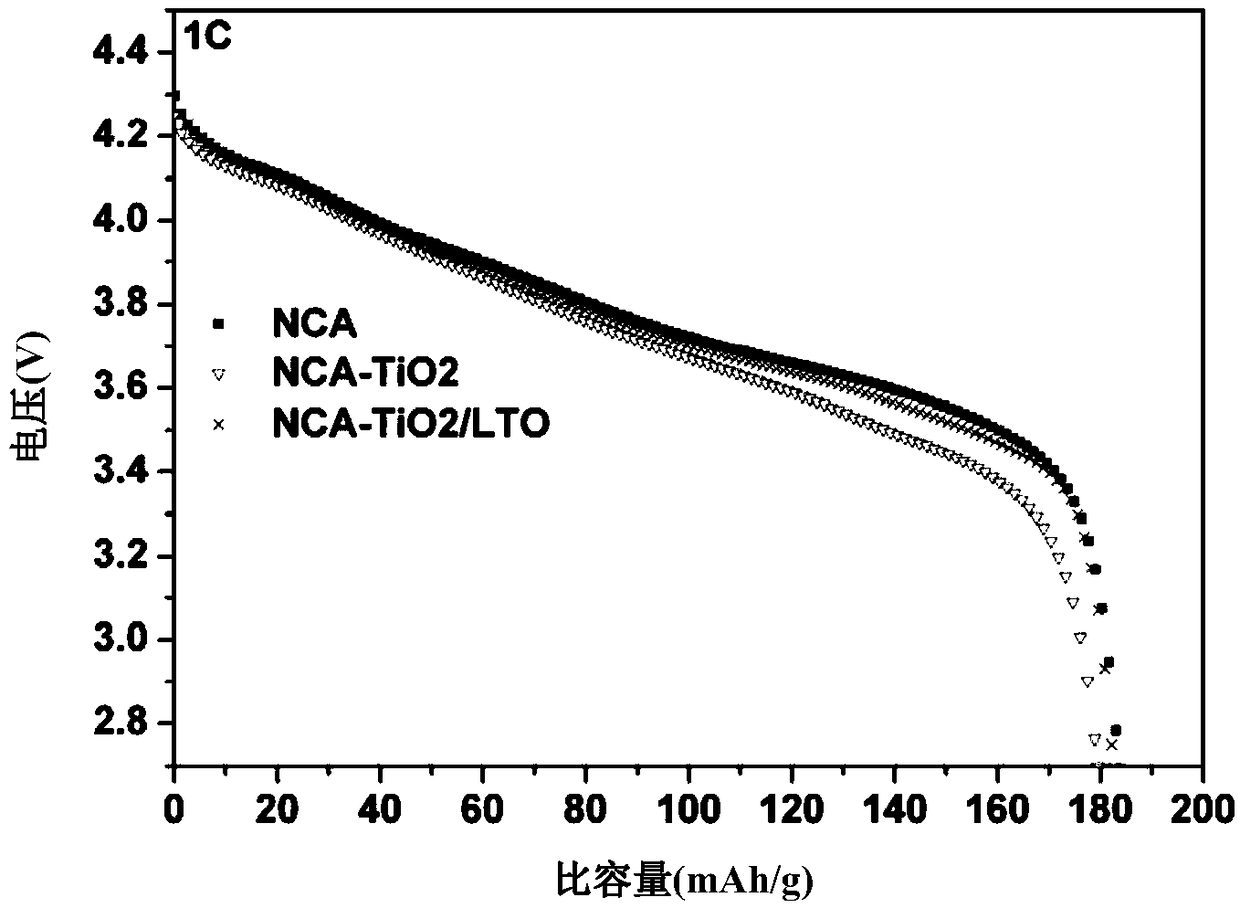

[0038] Example 2: NCA / TiO 2 / LTO cathode material

[0039] In this embodiment, NCA (nickel-cobalt-aluminum) is used as the positive electrode substrate, and TiO 2 As a high-temperature stable material, LTO (lithium titanate) is used as the positive electrode active material to prepare the positive electrode material NCA / TiO for lithium-ion batteries 2 / LTO.

[0040] Step 1: Same as Step 1 of Example 1, but NCA (nickel-cobalt-aluminum) is selected as the positive electrode substrate.

[0041] Step 2: Install the NCA positive electrode prepared above as a base material in the cavity of a magnetron sputtering machine (Beijing Techno Technology Co., Ltd., JCP-350M2). The target material TiO is provided in a weight percentage of 95 / 5 weight % 2 / LTO, place the target in the cavity of the magnetron sputtering machine. Then, the cavity was evacuated to 7.0×10 -4 Pa, and the substrate is heated, and after the temperature of the substrate is stabilized at 150° C., argon gas with ...

Embodiment 3

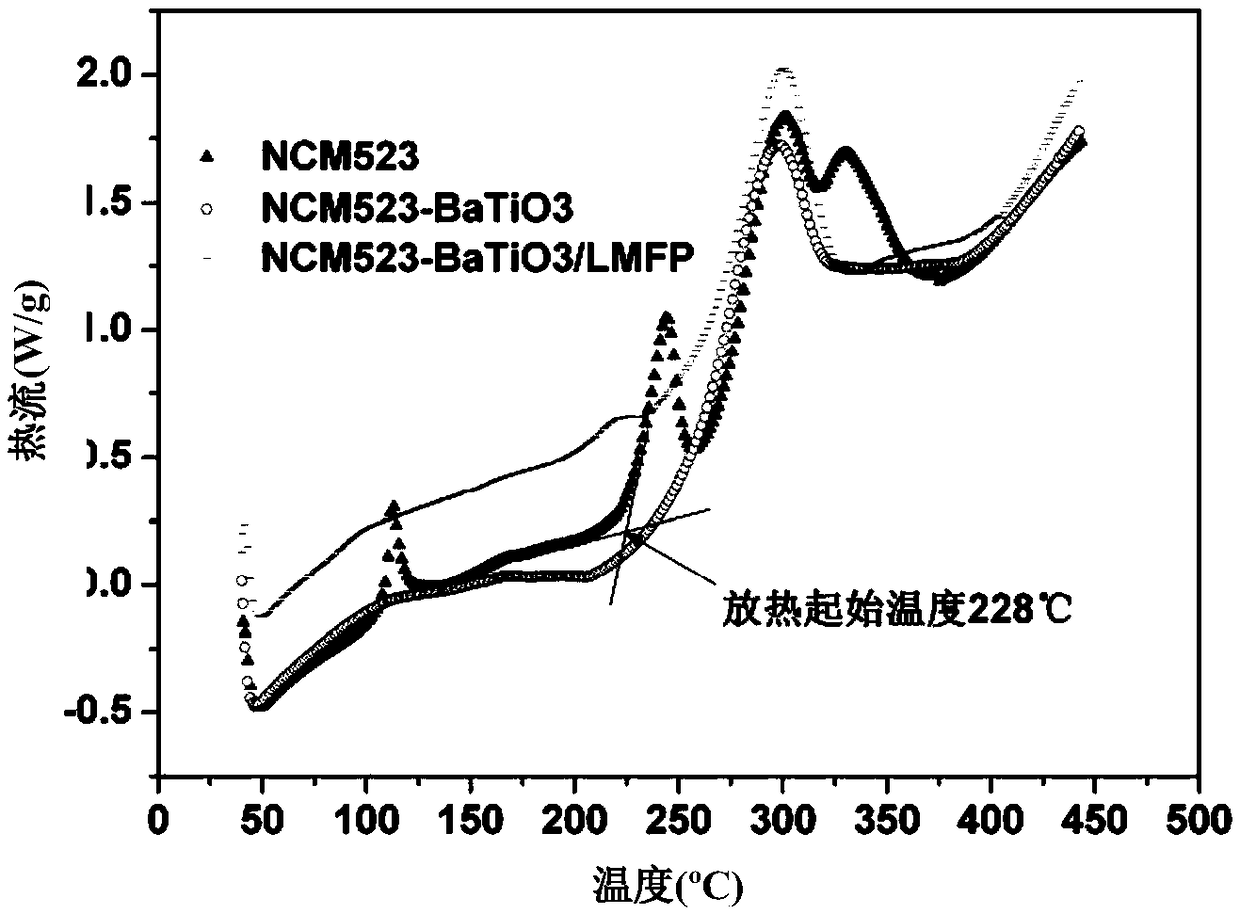

[0046] Example 3: NCM523 / BaTiO 3 / LMFP cathode material

[0047] In this embodiment, NCM523 (nickel-cobalt-manganese 523) is used as the positive electrode substrate, and BaTiO 3 As a high-temperature stable material, LMFP (lithium iron manganese phosphate) is used as the positive electrode active material to prepare the lithium ion battery positive electrode material NCM523 / BaTiO 3 / LMFP.

[0048] Step 1: Same as Step 1 of Example 1, but choose NCM523 (nickel-cobalt-manganese 523) as the positive electrode substrate.

[0049] Step 2: Install the NCM523 positive electrode prepared above as a base material in the cavity of a magnetron sputtering machine (Beijing Techno Technology Co., Ltd., JCP-350M2). The target material BaTiO is supplied in a weight percentage of 85 / 15% by weight 3 / LMFP, place the target in the cavity of the magnetron sputtering machine. Then, the cavity was evacuated to 7.5×10 -4 Pa, and the substrate is heated, and after the temperature of the substr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com