Simulation test device and method for researching process of friction between tires and road surface

A simulation test, tire technology, applied in the direction of using mechanical devices, automobile tire testing, measuring devices, etc., can solve the problems of low reliability, large energy consumption, increased equipment power, etc., to improve accuracy and reliability, improve Accurate, easy-to-place effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

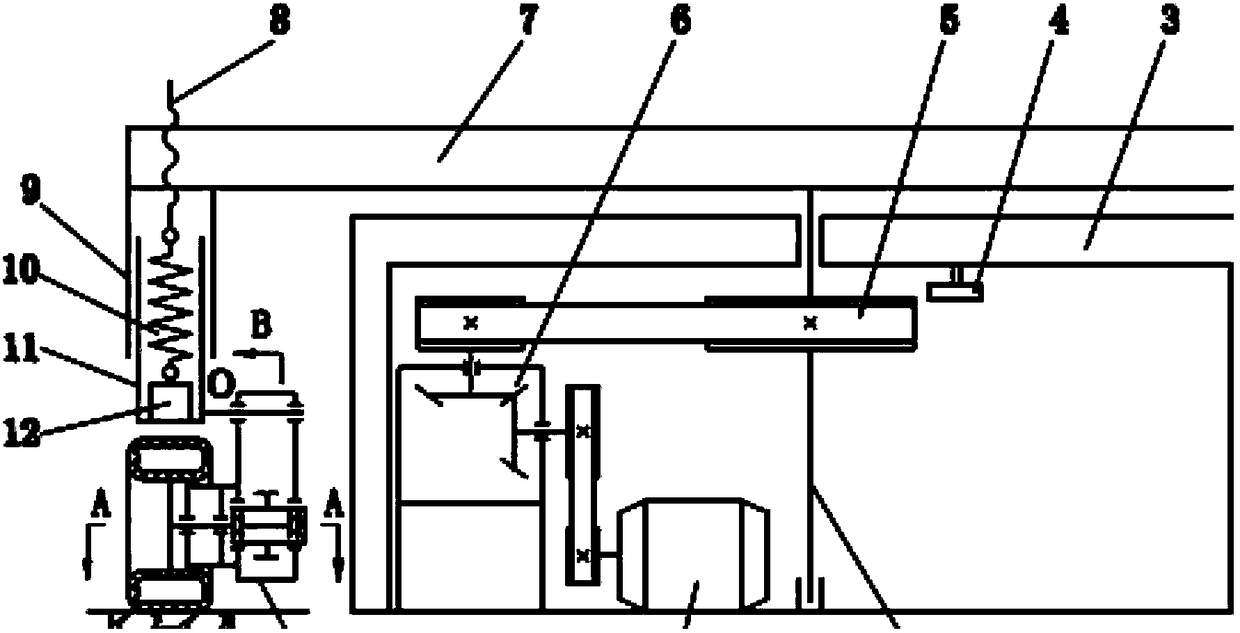

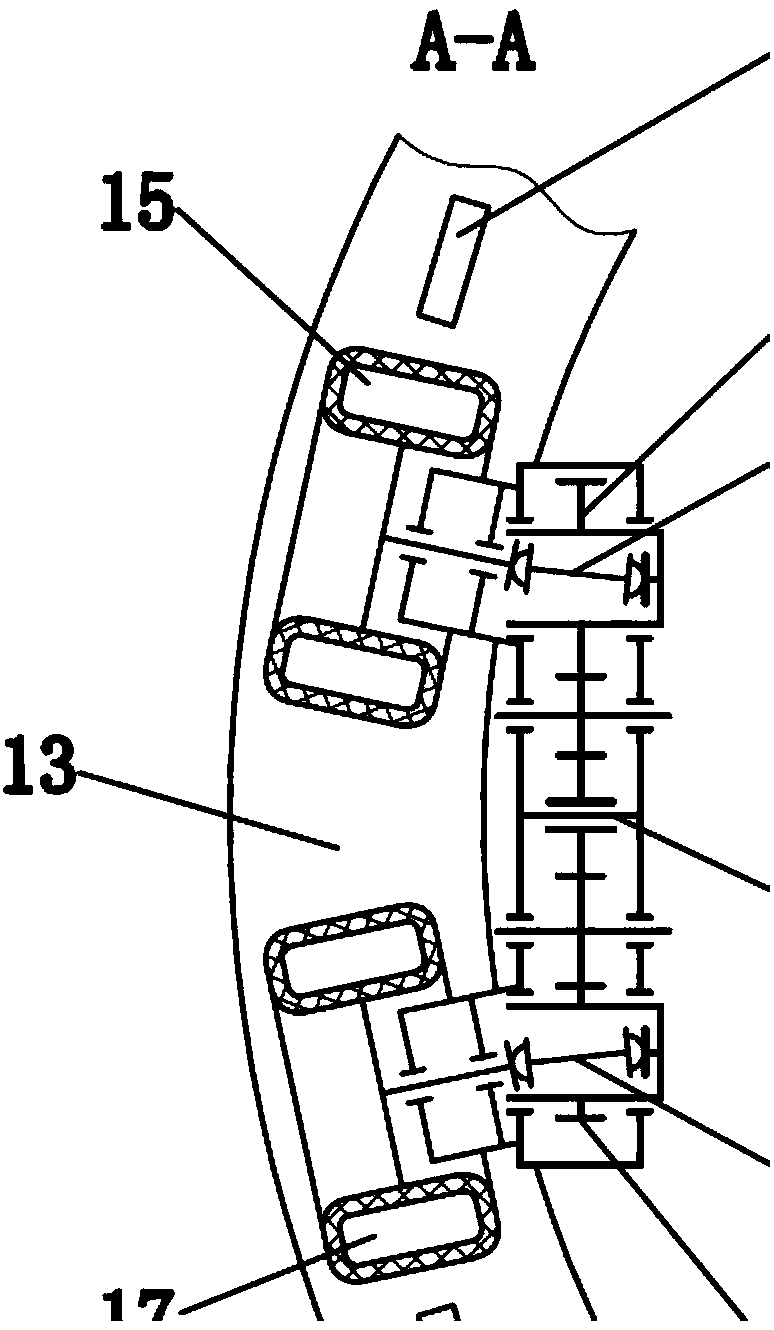

[0038] refer to Figure 1 to Figure 3 , a kind of simulation test device that is used for tire and road surface friction process research of the present invention comprises: driving device, transmission device, central shaft 2, rotating arm 7, loading device, transmission box 14, reference wheel 17, test wheel 15 and Test track 13. The transmission device is arranged between the driving device and the central shaft 2. The driving device can drive the central shaft 2 to rotate around its axis through the transmission device; The lower end of the central shaft 2 can be rotated on the base or foundation of the test device through bearings and other devices; both ends of the rotating arm 7 are connected with the transmission box 14 through the loading device, and the transmission box 14 can be applied perpendicular to the test by the loading device. The load of the track 13, when the rotating arm 7 rotates, the transmission box 14 can be driven by the loading device; the transmis...

Embodiment 2

[0053] refer to figure 1 , a kind of simulation test device that is used for tire and road surface friction process research of the present invention, motor 1 is connected with the input shaft of speed reducer 6 through transmission belt, and the output shaft of speed reducer 6 is connected with driven pulley 5 through belt, from The moving pulley 5 is fixed on the central shaft 2, the lower end of the central shaft 2 is supported on the ground by a bearing, the upper part of the central shaft 2 is supported on the support 3, and a rotating arm 7 is fixed on the top of the central shaft 2, and the two ends of the rotating arm 7 The end is provided with a first guide sleeve 9 and a screw 8, the screw 8 is located in the center of the guide sleeve, and a second guide sleeve 11 is arranged in cooperation with the inner wall of the first guide sleeve 9, and the second guide sleeve 11 is in the first guide The sleeve 9 can only move up and down and cannot rotate. A loading spring 1...

Embodiment 3

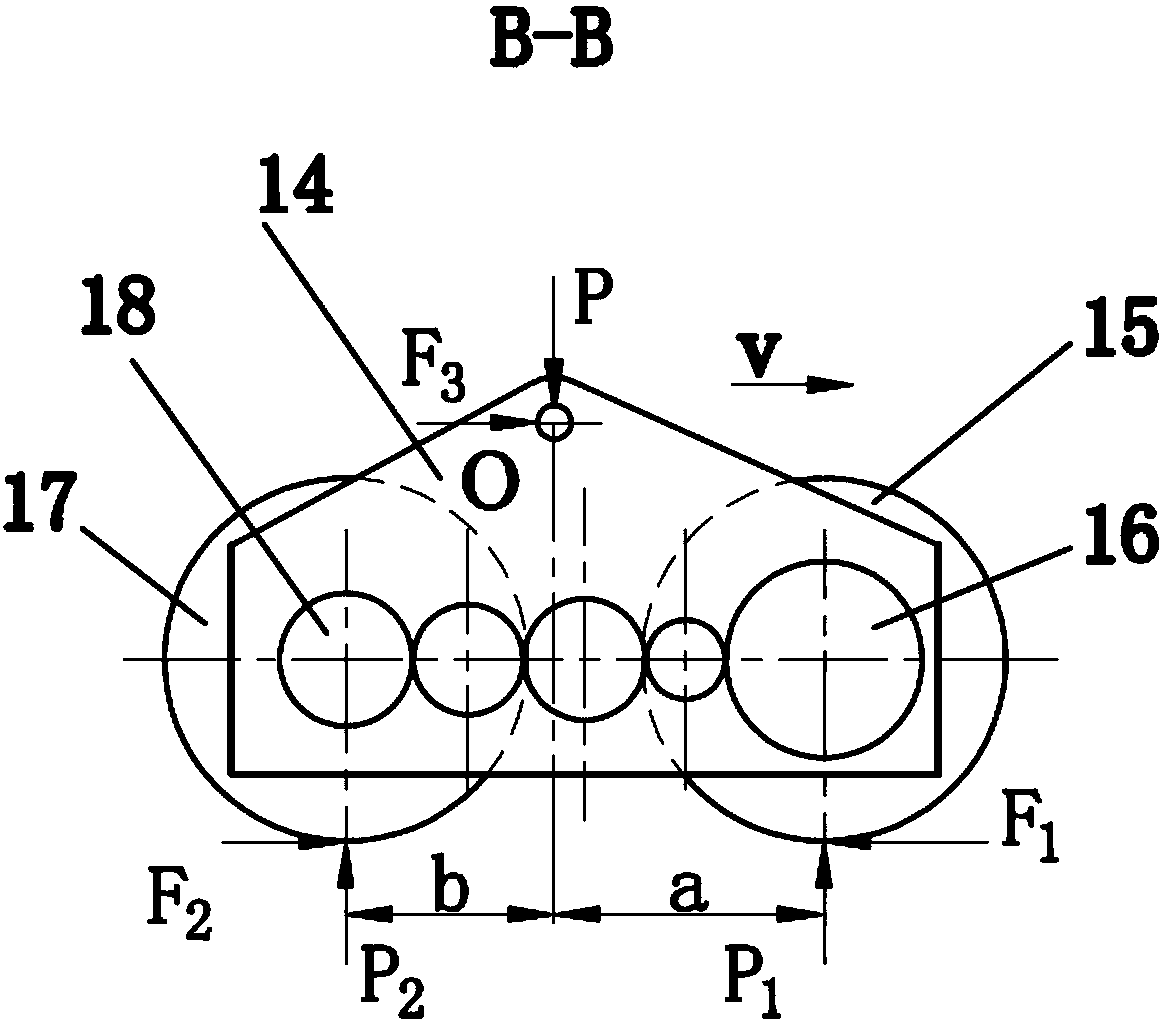

[0068] In this embodiment, the horizontal distance b from the axis of the reference gear 18 to the hinge point O is greater than the horizontal distance a from the axis of the test gear 16 to the hinge point O through structural adjustment, or the transmission box 14 acts on the two wheels through the counterweight adjustment. weight, so that P 2 1 ·z 2 / z 1 . Other structural parameters and test methods are the same as in Example 2.

[0069] At this time, the original reference wheel 17 produces a slipping motion and becomes a test wheel; the original test wheel 15 does not slip and becomes a reference wheel. The slipping process of the reference wheel 17 is similar to the slipping process of the driving wheel of the vehicle, and can be used to study the wear of the driving wheel of the vehicle.

[0070] At this time, the slip rate δ is calculated according to the following formula:

[0071] δ=1-z 2 / z 1 (4)

[0072] The coefficient of friction f between the referenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com