Fabricated concrete frame structure locally reinforced through prefabricated ultra-high performance concrete (UHPC) shells

A technology of prefabricated concrete and local reinforcement, applied in truss structures, building structures, joists, etc., can solve the problems of difficult construction of UHPC materials, concentrated damage of beams and columns, and insufficient adaptability, so as to reduce the difficulty of fabrication and construction, increase Structural ductility, effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

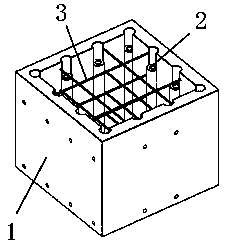

[0036] Such as figure 1 As shown, the prefabricated annular UHPC shell at the base of the column is made first, and the annular shell is surrounded by four UHPC surfaces 1; the annular UHPC shell is prefabricated with the grouting sleeve 2 and the composite stirrup 3 at the column base; the annular prefabricated UHPC shell at the base of the column is high A short distance from the grouting sleeve 2 can be within the range of the connection height of the column feet, so that the section stiffness and strength gradually change in steps, so as to avoid local damage of ordinary concrete at the section change position and affect the performance of the component.

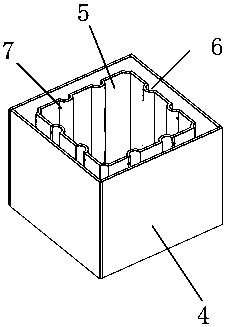

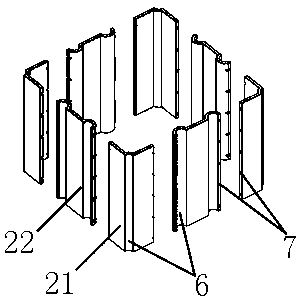

[0037] figure 1 The annular prefabricated UHPC shell of the column foot is made of a detachable assembled formwork; the manufacturing process is as follows: Figure 2-3As shown, the det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com