Production technology of polyester-wool blended smooth double face woolen cloth

A production process, double-faced fabric technology, applied in the direction of enzyme/microbial biochemical treatment, textile, biochemical fiber treatment, etc., can solve the inconvenience of the textile process and other problems, achieve excellent antistatic performance, reduce the amount of use, and reduce the effect of added amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

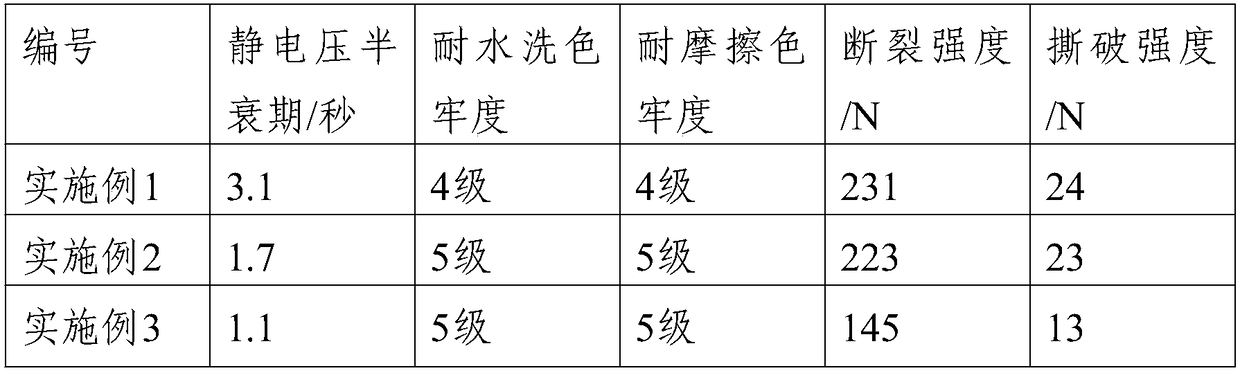

Examples

Embodiment 1

[0031] A kind of production technology of wool polyester blended smooth wool double-faced woolen, described production technology comprises following process steps:

[0032] The first step: pretreatment of raw materials

[0033] Pretreatment of polyester fiber strips: prepare lipase pretreatment solution, dip the polyester fiber strips into the pretreatment solution and pass them through rolls, two dips and two rolls, and stack the dipped polyester fibers in a 50°C thermostat for 6 hours. Boil at 100°C for 10 minutes, wash once at 60-70°C, and once at 30-40°C; soak the washed polyester fiber strips in a sodium hydroxide solution with a concentration of 0.02g / L for 30 minutes, wash once with water, and dry in the air. dyeing. The lipase treatment conditions are as follows: the dosage of the industrial lipase is 60g / L, the excess rate is 95-100%, and the pH value of the lipase pretreatment solution is 7.

[0034]Pretreatment of wool fiber: Prepare protease pretreatment solutio...

Embodiment 2

[0062] On the basis of embodiment 1, the difference of embodiment 2 and embodiment 1 production process is:

[0063] The first step: pretreatment of raw materials

[0064] Pretreatment of polyester fiber strips: stack the polyester fiber strips after padding in a 50°C incubator for 8 hours; soak the washed polyester fibers in a sodium hydroxide solution with a concentration of 0.03g / L for 20 minutes, and wash them once. Allow to dry ready to stain. The lipase treatment condition is: the consumption of the industrial lipase is 80g / L.

[0065] Pretreatment of wool fibers: stack the padded Australian wool tops and sheep wool tops in a 45°C incubator for 30 minutes, adjust the pH value to 3-4 with acetic acid to kill enzymes, wash once at 60-70°C, and wash once at 30-40°C Wash once with water; the dosage of the protease is 8g / L.

[0066] The second step: weighing and dyeing raw material fibers

[0067] Dyeing process of polyester fiber: use alkali-resistant disperse dyes, the ...

Embodiment 3

[0075] On the basis of embodiment 1, the difference of embodiment 2 and embodiment 1 production process is:

[0076] The first step: pretreatment of raw materials

[0077] Pretreatment of polyester fiber strips: stack the polyester fiber strips after padding in a 60°C thermostat for 10 hours; soak the washed polyester fiber strips in a sodium hydroxide solution with a concentration of 0.04g / L for 20 minutes, and wash them once , dry and ready to dye. The lipase treatment condition is: the consumption of the industrial lipase is 100g / L.

[0078] Pretreatment of wool fibers: stack the padded Australian wool tops and sheep wool tops in a 50°C incubator for 60 minutes, adjust the pH value to 3-4 with acetic acid to kill enzymes, wash once at 60-70°C, and wash at 30-40°C 1 time; the dosage of the protease is 10g / L.

[0079] The second step: weighing and dyeing raw material fibers

[0080] The dyeing process of polyester fiber strips: use alkali-resistant disperse dyes, the conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com