Anisotropic conductive film, connection method, and joined body

An anisotropic, conductive connection technology used in conductive adhesives, conductors, non-insulated conductors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

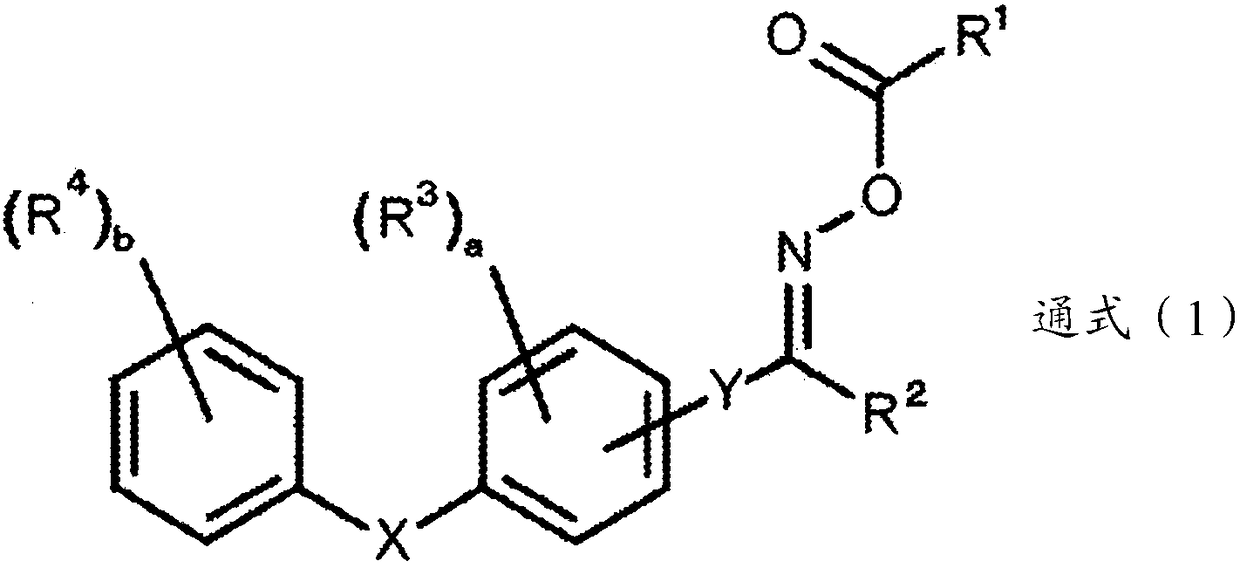

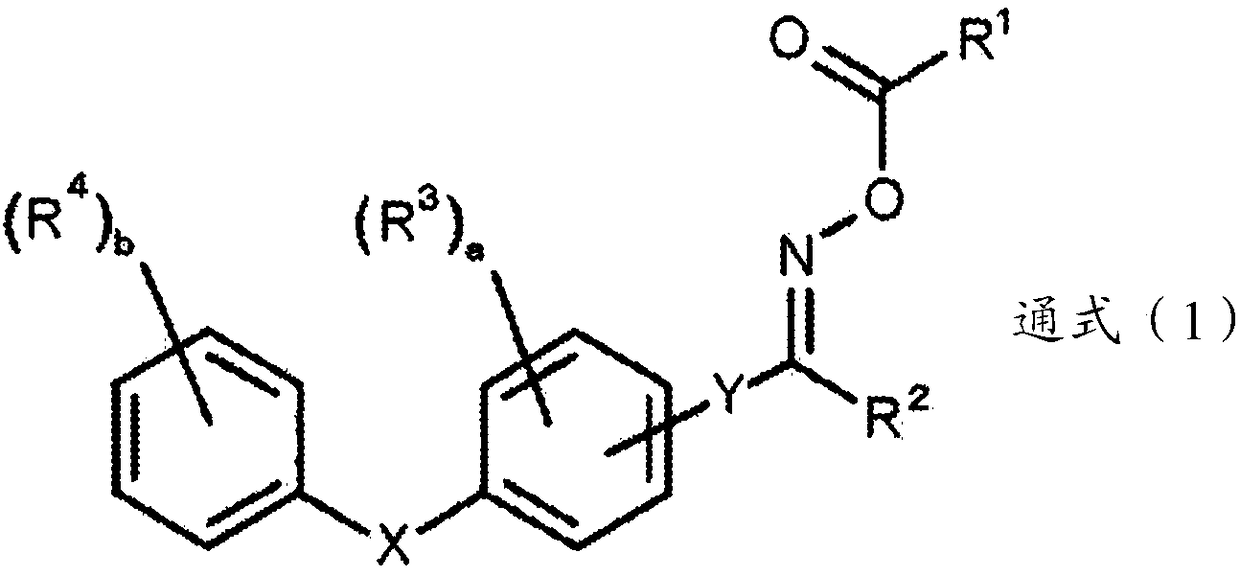

Method used

Image

Examples

Embodiment 1

[0132]

[0133]47 parts by mass of phenoxy resin (product name: PKFE, manufactured by Pakistan Industrial Co., Ltd.), 35 parts by mass of urethane acrylate (product name: EBECRYL600, manufactured by Daicel-Cytec Co., Ltd.), acrylic acid monomer (product name: A -DCP, manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) 5 parts by mass, silane coupling agent (product name: KBM-503, manufactured by Shin-Etsu Chemical Industry Co., Ltd.) 2 parts by mass, oxime ester type photopolymerization initiator (product name: IRGACURE OXE01, 3 parts by mass of BASF), 0.5 part by mass of anthracene, and 6 parts by mass of conductive particles (product name: AUL704, manufactured by Sekisui Chemical Co., Ltd., average particle diameter: 4 μm) were uniformly mixed. The mixed compound was coated on silicone-treated PET (polyethylene terephthalate) with a bar coater so that the average thickness after drying was 14 μm, and dried at 70° C. for 5 minutes. , making a conductive conductive fi...

Embodiment 2 to 3、 comparative example 1 to 4

[0150]

[0151] As shown in the following Table 1, in Example 1, except not adding anthracene or changing other compounds, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0152] Evaluation was carried out in the same manner as in Example 1. The results are shown in Table 1.

[0153] [Table 1]

[0154]

[0155] In Examples 1-3, the result which was excellent in the conduction resistance was obtained both when it was exposed to a fluorescent lamp and when it was not exposed to a fluorescent lamp. In addition, the reaction rate after connection is high not only in the opening but also in the light-shielding part, and the adhesive strength is excellent.

[0156] Among them, both Examples 2 and 3 containing anthracene having a phenyl group as an additive exhibited particularly excellent adhesive strength.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com