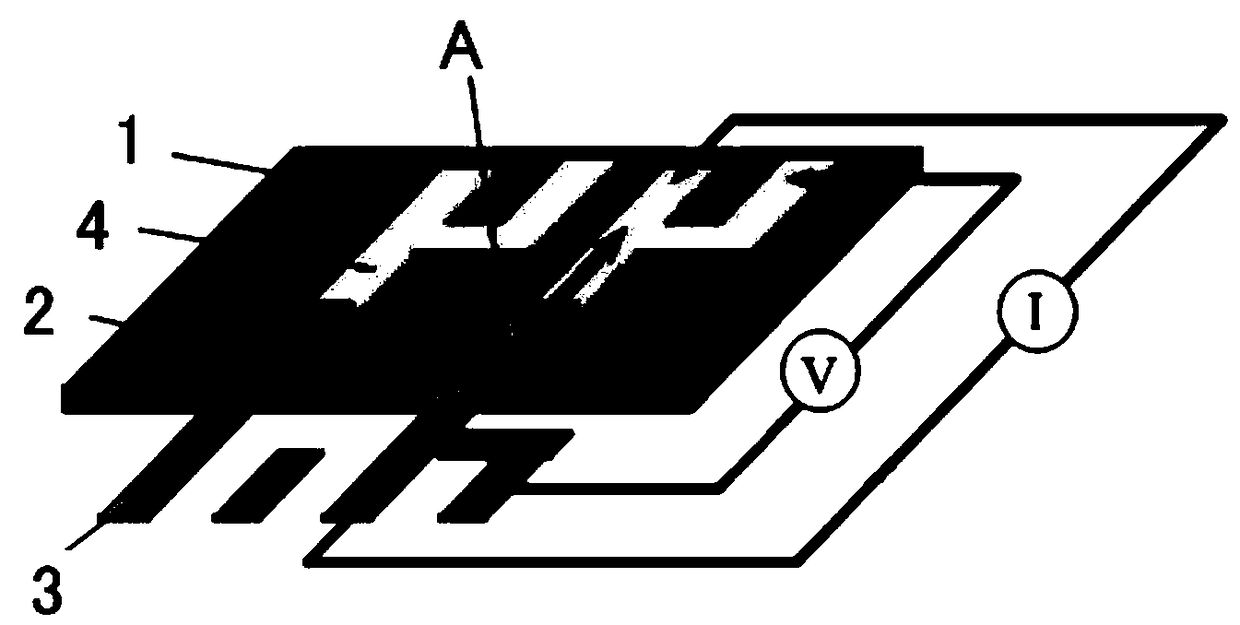

Anisotropic conductive film, connection method, and bonded body

An anisotropic, conductive connection technology, applied in the direction of conductive adhesive connection, connection, film/sheet adhesive, etc., can solve the problem that anisotropic conductive film cannot be obtained

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

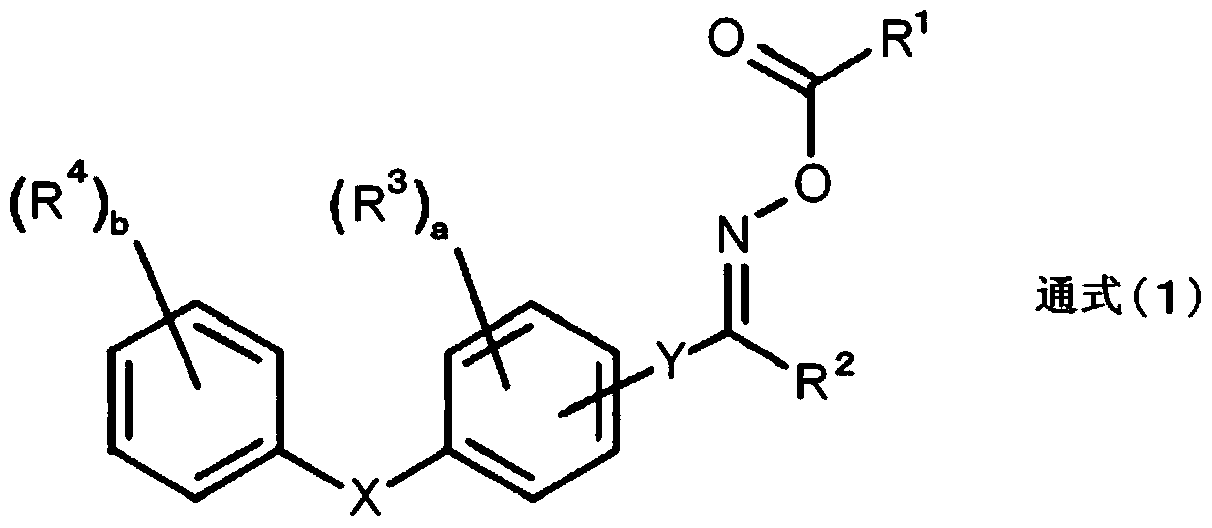

Method used

Image

Examples

Embodiment 1

[0133]

[0134] 47 parts by mass of phenoxy resin (trade name: PKFE, manufactured by Pakistan Industrial Co., Ltd.), 35 parts by mass of urethane acrylate (trade name: EBECRYL600, manufactured by Daicel Cytec Co., Ltd.), acrylic acid monomer (trade name: A -DCP, manufactured by Shin-Nakamura Chemical Industry Co., Ltd.) 5 parts by mass, silane coupling agent (trade name: KBM-503, manufactured by Shin-Etsu Chemical Industry Co., Ltd.) 2 parts by mass, oxime ester type photopolymerization initiator (trade name: Irugakyua OXE01, manufactured by BASF Corporation) 3 parts by mass, IRGALITE RED CBNL (manufactured by BASF Corporation, 0.5 mass % toluene solution has a transmittance of 63% of light at a wavelength of 365 nm and a transmittance of 20% of light at a wavelength of 400 nm) 0.5 parts by mass, and 6 parts by mass of conductive particles (trade name: AUL704, manufactured by Sekisui Chemical Co., Ltd., average particle diameter: 4 μm) were uniformly mixed. Coat the mixed co...

Embodiment 2

[0150]

[0151] Except having changed 3 mass parts of oxime ester type photoinitiators into 6 mass parts in Example 1, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0152] Evaluation was performed in the same manner as in Example 1. Table 1 shows the results.

Embodiment 3

[0154]

[0155] Except having changed 3 mass parts of oxime ester type photoinitiators into 1 mass part in Example 1, it carried out similarly to Example 1, and obtained the anisotropic conductive film.

[0156] Evaluation was performed in the same manner as in Example 1. Table 1 shows the results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com