Er-doped fluorophosphate tellurite glass fiber for fabricating high-power wideband fiber amplifier

An erbium fluoride tellurate, fiber amplifier technology, applied in lasers, cladding fibers, optical waveguides, etc., can solve problems such as reducing the water resistance of glass and affecting applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

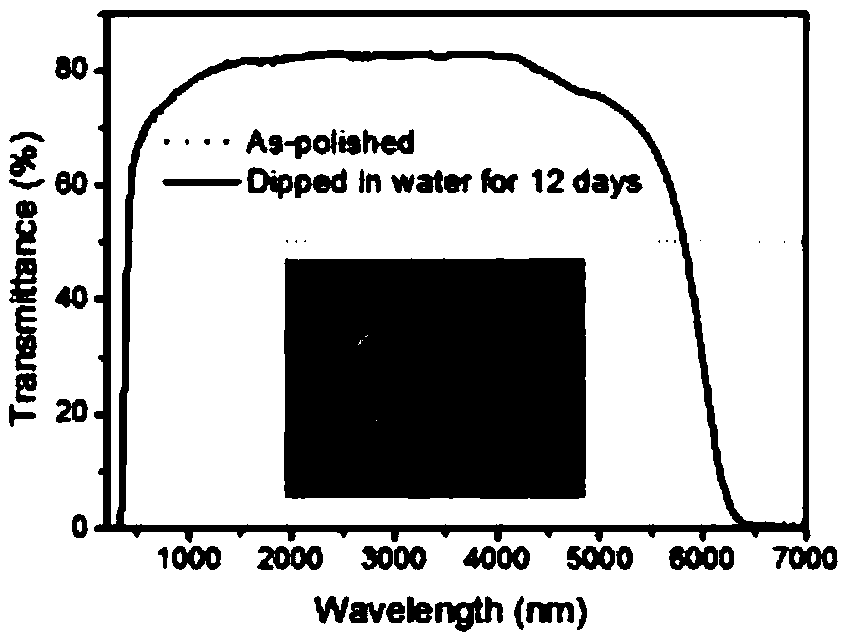

[0036] Preparation of fluorotellurite glass

[0037] The first step: according to the molar ratio of TeO 2 :BaF 2 :Y 2 o 3 (TBY)=70:20:10 Take by weighing 15g of raw materials, put the weighed raw materials into an agate mortar and grind for 30 minutes to make the raw materials evenly mixed; place the mixed raw materials in a 20ml platinum crucible and put Melt in an electric furnace heated to 950°C; after 30 minutes, place the molten TBY glass in a preheated mold, and after the glass is cooled and formed, place it in an electric furnace heated to 380°C for heat preservation and annealing; after 3 hours, close Electric furnace power supply; take it out after the furnace temperature has cooled to room temperature, and the above process is completed in the glove box. The prepared fluorotellurite glass was ground and polished to ~2.5 mm for measurement. Polished samples such as figure 2 shown in the inset.

[0038] Water Resistance Test

[0039] Use spectrophotometer UV3...

Embodiment 2

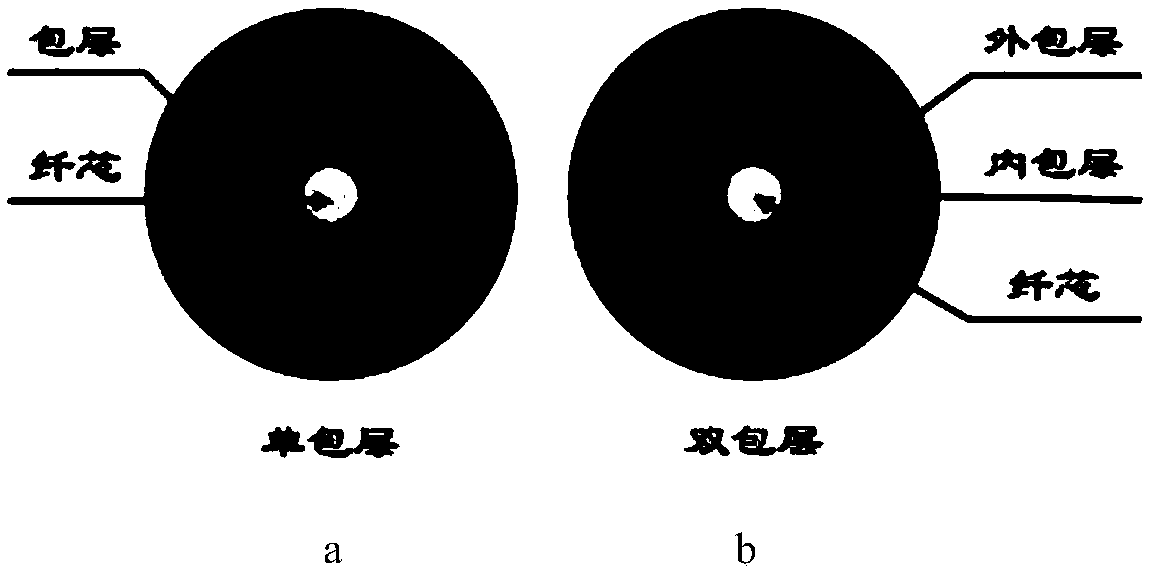

[0041] Preparation of erbium-doped fluorotellurite glass fiber and its application in broadband optical amplifier;

[0042] The first step: according to the molar ratio of TeO 2 :BaF 2 :Y 2 o 3 :Er 2 o 3 (TBYE)=70:20:9.5:0.5 and TeO 2 :BaF 2 :Y 2 o 3(TBY-65)=65:25:10 Weigh 15g of raw materials respectively, put the weighed raw materials into an agate mortar and grind for 30 minutes, so that the raw materials are evenly mixed; place the mixed raw materials in a 20ml platinum crucible and Put it into an electric furnace that has been heated to 950°C for melting; after 30 minutes, take out the molten TBY-65 glass liquid and pour it into a preheated copper mold (cylinder), and lift the mold up quickly to let the The cooled molten glass flows out from the bottom of the mold to form a glass tube; then the molten TBYE glass is taken out and poured into the glass tube, and after the glass is cooled and formed, it is placed in an electric furnace heated to 400°C for heat prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com