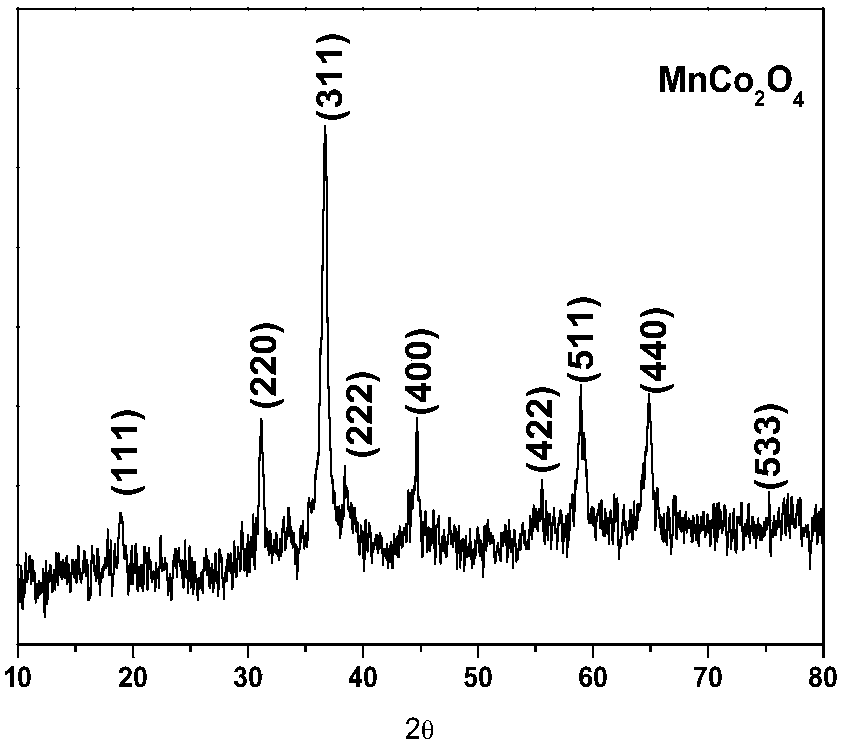

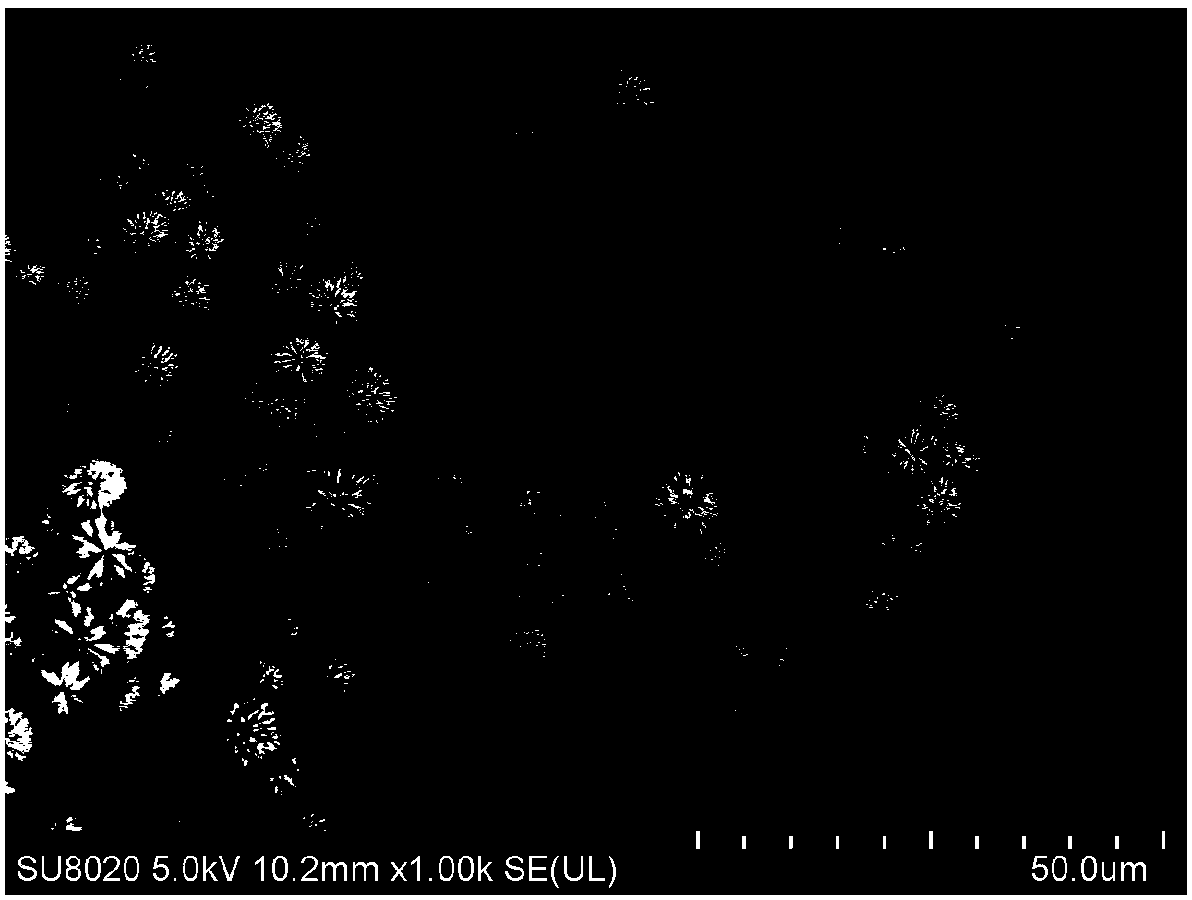

Three-dimensional structure carbon-coated manganese cobalt oxide nanowire material, preparation method and application

A nano-manganese cobalt oxide and three-dimensional structure technology, which is applied in nanotechnology, nanotechnology, structural parts, etc., can solve problems such as poor cycle stability, achieve controllable process, increase active sites, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] First place the copper foam in acetone, ethanol, and deionized water for 15 minutes, and then soak it in analytically pure hydrochloric acid (HCl, with a mass fraction of 36-38%) for two hours. Rinse with deionized water, and then ultrasonicate in 5% dilute hydrochloric acid solution and deionized water for 15 minutes respectively. After cleaning, freeze in a freeze dryer for 12 hours and dry for 12 hours. Cobalt nitrate hexahydrate 0.5mml (Co(NO 3 ) 2 ·6H 2 O, 99%), manganese nitrate 1mml (Mn(NO 3 ) 2 , 10mml urea (CH 4 N 2 O, 99.5%) and 0.5mml ammonium fluoride (NH 4 F, 96%) was dissolved in 40 ml of high-purity deionized water (18.25 MΩ·cm-1), and stirred by a magnetic stirrer for 30 minutes to form a pink transparent solution. Fix the copper foam on the bottom of the polytetrafluoroethylene liner, pour the above solution into a 50ml polytetrafluoroethylene liner, and put the liner into a stainless steel reaction kettle. The whole stainless steel reaction ket...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com