U-shaped double-wall socket and spigot type pipe joint and installing method thereof

A pipe interface, socket-type technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, passing element, etc., can solve the problems such as the lack of positioning of the rubber sealing ring, the increase of the drainage pipe flow, and the pollution of groundwater sources. , to reduce the contact area, increase the service life, and achieve good seismic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

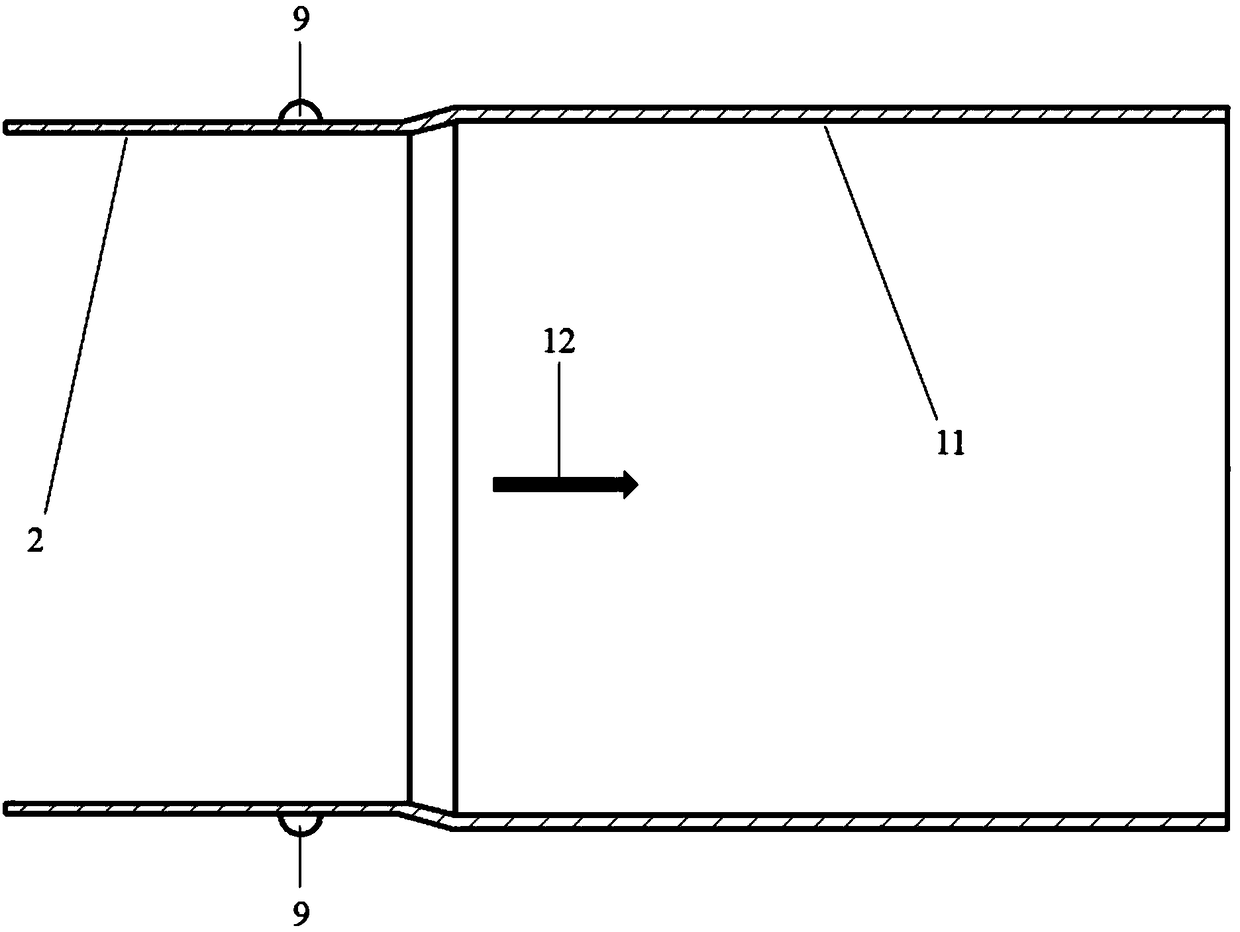

[0067] The U-shaped double-wall socket-type pipe joint of this embodiment is composed of three parts: a U-shaped double-wall socket end 1, a socket end 2 and a rubber sealing ring. The U-shaped slot 8 is formed by making the socket end 1 into a double-layer pipe wall, so that the width of the slot is consistent with the thickness of the pipe wall at the socket end 2. After installation, they fit together to form a good airtight performance; at the same time, the rubber seal The ring 4 is placed at the bottom of the U-shaped slot 8, and after being installed in place, the socket end 1 and the socket end 2 squeeze and compress the rubber sealing ring 4 to produce a double sealing effect. The inlet end of the inner side of the outer wall of the groove 5 is provided with a groove 7, which fits with the convex contact 9 on the outer wall of the socket end 2 during installation to form a lock to avoid axial slippage between the socket end 1 and the socket end 2. Strengthening ribs 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com