Method for preparing W-doped Al2O3 high-resistance membrane through atomic layer deposition

An atomic layer deposition and high-resistance technology, which is applied in coating, metal material coating process, gaseous chemical plating, etc. Excellent thermal stability, simple preparation process, and controllable deposition process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

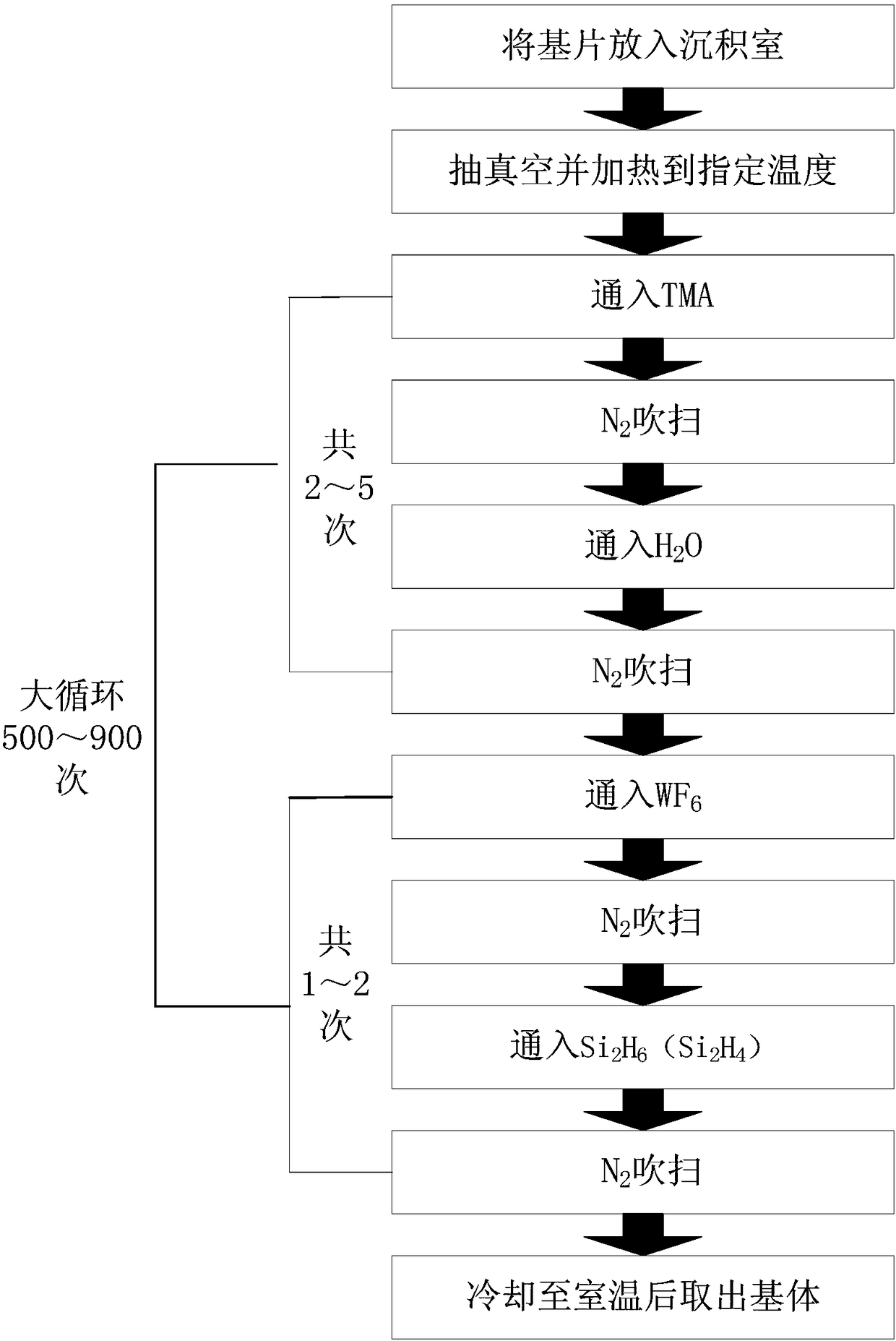

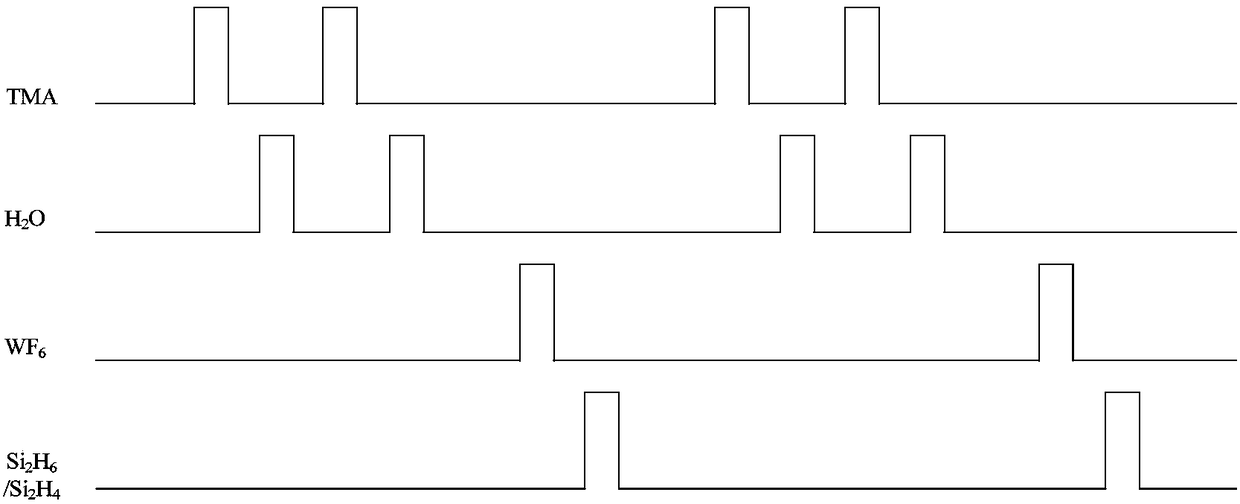

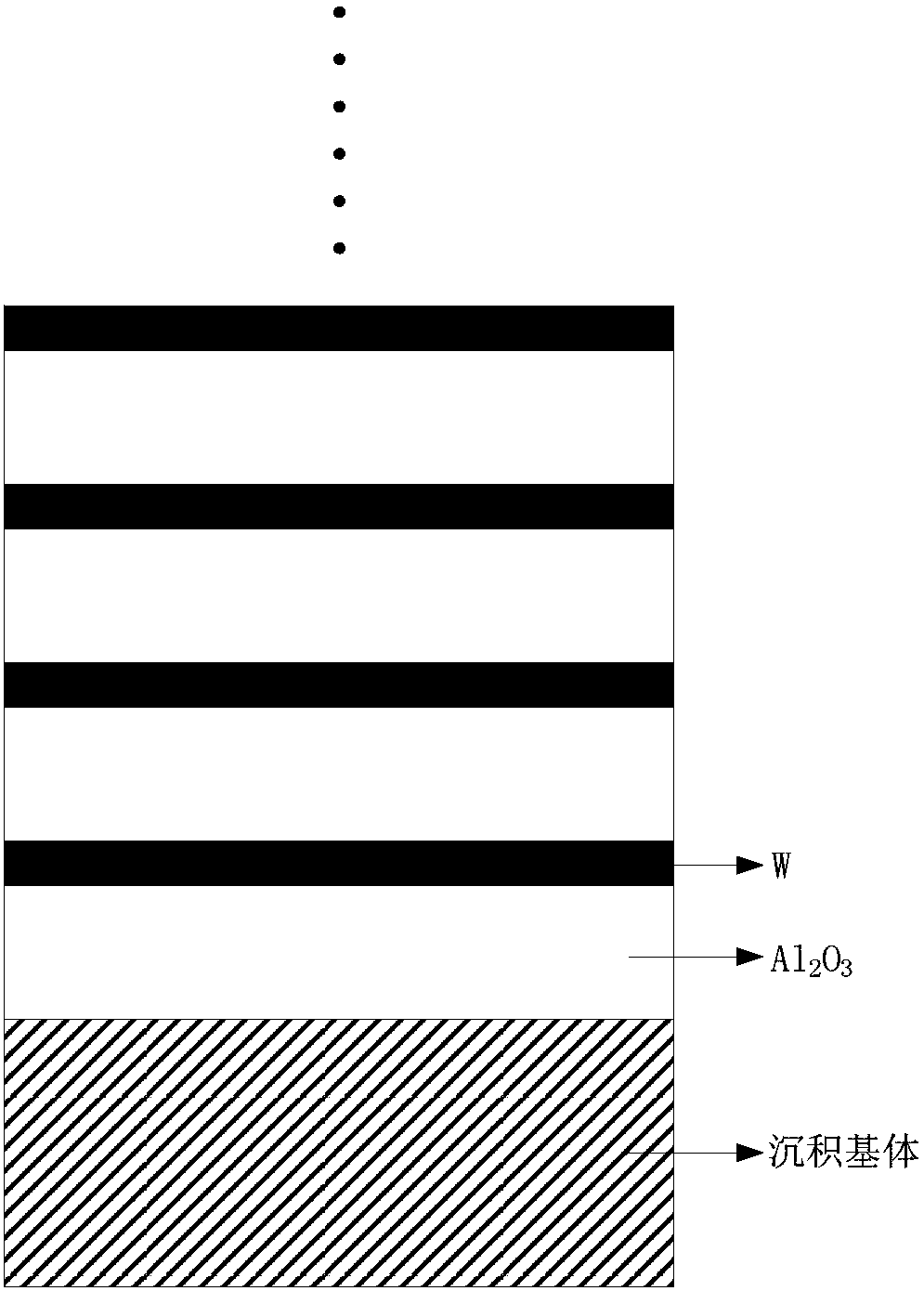

[0062] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 O 3 deposition, ie TMA / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 5 cycles, W deposition is performed once, that is, WF 6 / N 2 / Si 2 H 6 (Si 2 H 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 5 times Al 2 O 3 The deposition cycle and one W deposition constitute a large cycle. The deposition is stopped after 500 large cycles. After the temperature of the deposition chamber drops to room temperature, the deposition chamber is opened, and the deposited W-doped Al 2 O 3 substrate of the film.

Embodiment 2

[0064] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 O 3 deposition, ie TMA / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 4 cycles, W deposition is performed once, that is, WF 6 / N 2 / Si 2 H 6 (Si 2 H 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 4 times Al 2 O 3 The deposition cycle and one W deposition constitute a large cycle. The deposition is stopped after 580 large cycles. After the temperature of the deposition chamber drops to room temperature, the deposition chamber is opened and the deposited W-doped Al 2 O 3 substrate of the film.

Embodiment 3

[0066] Put the substrate into the atomic layer deposition chamber and evacuate to 10 -2 Pa~10 -5 Pa, and the substrate is heated to 200°C to start Al 2 O 3 deposition, ie TMA / N 2 / H 2 O / N 2 =(0.1s / 3s / 0.1s / 3s), after 3 cycles, W deposition is performed once, that is, WF 6 / N 2 / Si 2 H 6 (Si 2 H 4 ) / N 2 =(0.5s / 5s / 0.5s / 5s), 3 times Al 2 O 3 The deposition cycle and one W deposition constitute a large cycle. The deposition is stopped after 700 large cycles. After the temperature of the deposition chamber drops to room temperature, the deposition chamber is opened and the deposited W-doped Al 2 O 3 substrate of the film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com