Method for reducing viscosity of heavy oil

A heavy oil and catalyst technology, applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as short start-up period, difficult operation, manual decoking, etc., to reduce the tendency of polymerization coke, and reduce harsh operation Degree, the effect of inhibiting polymerization coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Preparation of basic catalyst support

[0018] Get 300 grams of magnesium nitrate, polyethylene glycol (the purpose of adding polyethylene glycol is to promote the uniform distribution of catalyst active components, increase the surface area of catalyst, and improve the number of active centers. In the roasting process, it can be decomposed and converted into water and CO 2 and remove) 50 grams, completely dissolved in ion-free water, fully stirred and mixed, and dried at 110°C (the main purpose of drying is to remove the water in the solution, and the active components in the solution are adsorbed on the inner and outer surfaces of the carrier, and are in a solid state , the physical properties have not changed. After roasting, chemical changes will occur, and the salts will decompose into oxides) for 8 hours. After 24 hours, the temperature was uniformly lowered to room temperature to obtain a basic catalyst carrier. The particles of the catalyst carrier are crushe...

Embodiment 2

[0020] Preparation of basic catalyst

[0021] 1. Weigh 150.0 grams of the catalyst precursor ZT, dissolve it in ion-free water with nickel nitrate, ammonium molybdate, and boric acid, and prepare a mixed aqueous solution. Preheat the aqueous solution to 60°C, and add the prepared catalyst carrier , impregnated, stirred continuously for 1.5 hours, and stood still for 12 hours. After the impregnation, the temperature was raised to 120°C for drying, and the drying was completed at a constant temperature of 120°C for 12 hours; The catalyst CAT-C with basic carrier was obtained. MoO in the catalyst 3 The content of NiO is 10.6wt%, the content of NiO is 3.6wt%, and the content of B is 2.5wt%.

Embodiment 3

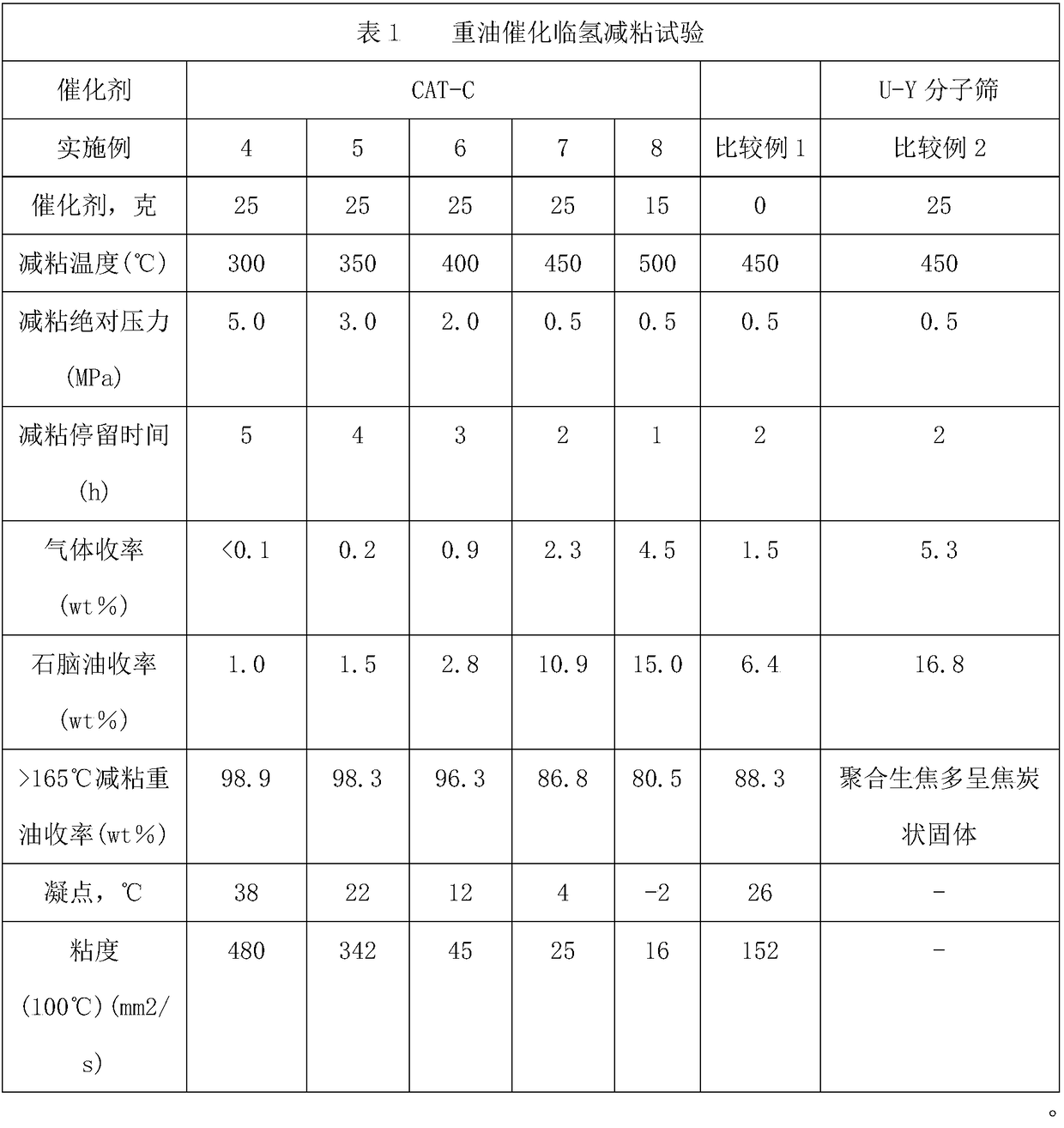

[0023] Evaluation of Hydrogen Application of Heavy Oil + Catalyst

[0024] The catalyst evaluation device is a 1000ml stainless steel kettle-type magnetic sealed stirring device. Take 25 grams of catalyst CAT-C, 500 grams of heavy oil, 380°C-600°C fraction, freezing point 86°C, total sulfur content 2.65wt%, 100°C viscosity 920mm 2 / s, add the catalyst and heavy oil into the reactor, after the seal pressure test is qualified, replace the reaction system with nitrogen for 3 times, start to raise the temperature, the temperature rise rate is 10°C / min, the temperature rises to 150°C, turn on the stirring device, the speed is 400rpm, Supplement hydrogen to the reaction system to 3.0MPa, continue to uniformly raise the temperature to 450°C, control the reaction pressure to 6.0MPa, stabilize for 3 hours, cool to 60°C, reduce the pressure to normal pressure, take out the reaction product, and carry out fractional distillation, of which the gas product is 2.1wt %, gasoline fraction 12....

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| dew point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com