Adhesive for potting of integrated circuit board and preparation method thereof

A technology for integrated circuit boards and adhesives, applied in the direction of adhesives, adhesive additives, adhesive types, etc., can solve problems affecting the stability and reliability of integrated circuit boards, poor flame retardancy, and difficult heat dissipation, etc. The method is simple and easy to implement, the effect of improving performance stability and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

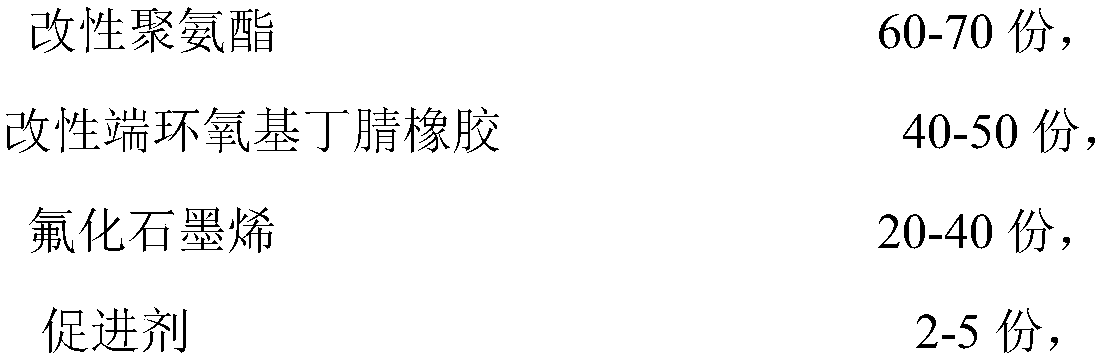

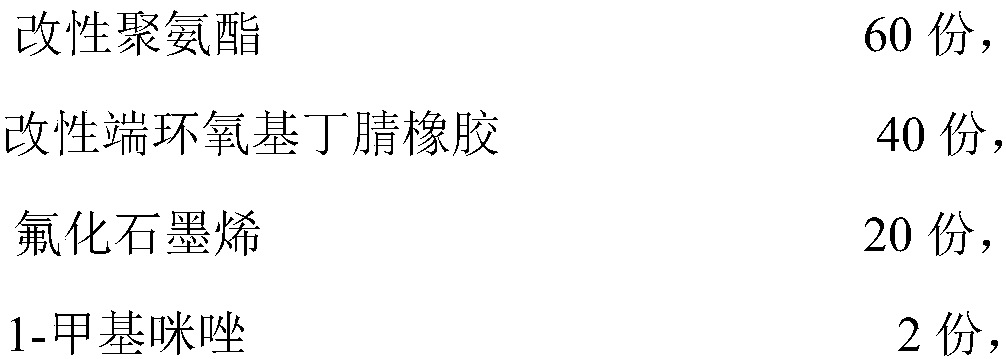

[0023] An adhesive for encapsulating integrated circuit boards, comprising the following raw materials calculated in parts by weight:

[0024]

[0025] The preparation method of the modified polyurethane comprises the following steps: dissolving 40 g of polyurethane in 200 g of dimethyl sulfoxide, and adding 10 g of silane coupling agent KH560 and 30 g of tetrabutylammonium bromide to it, and stirring and reacting at 110° C. After 5 hours, wash with water 5 times, then dewater with anhydrous magnesium sulfate, filter and remove the solvent by rotary evaporation at 50°C;

[0026] The preparation method of the modified epoxy-terminated nitrile rubber comprises the steps of adding 30 g of epoxy-terminated nitrile rubber into 100 g of ethanol, and adding 1,3,5,7-tetrakis(4-amino) Phenyl)adamantane 10g, at 60°C

[0027] The reaction was stirred under low temperature for 6 hours, and then the solvent was removed by rotary evaporation at 50°C.

Embodiment 2

[0029] An adhesive for encapsulating integrated circuit boards, comprising the following raw materials calculated in parts by weight:

[0030]

[0031] The preparation method of the modified polyurethane comprises the following steps: dissolving 45 g of polyurethane in 230 g of N-methylpyrrolidone, and adding 13 g of silane coupling agent KH560 and 30 g of tetrabutylammonium bromide to it, and stirring at 113° C. React for 6 hours, then wash with water 6 times, then remove water with anhydrous magnesium sulfate, filter and remove solvent by rotary evaporation at 53°C;

[0032] The preparation method of described modified epoxy-terminated nitrile rubber comprises the steps of: adding 35 g of epoxy-terminated nitrile rubber in 120 g of isopropanol, and adding 1,3,5,7-tetrakis (4 -Aminophenyl)adamantane 10g, stirred and reacted at 65°C for 7 hours, and then removed the solvent by rotary evaporation at 53°C.

Embodiment 3

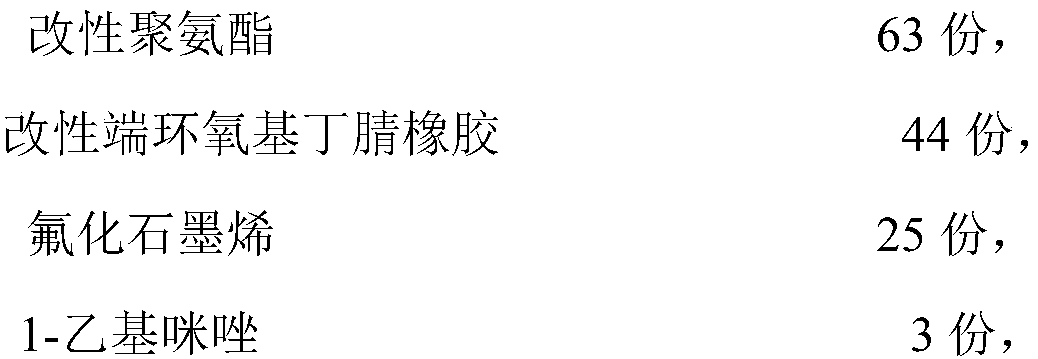

[0034] An adhesive for encapsulating integrated circuit boards, comprising the following raw materials calculated in parts by weight:

[0035]

[0036] The preparation method of the modified polyurethane comprises the following steps: dissolving 50 g of polyurethane in 270 g of N,N-dimethylformamide, and adding 17 g of silane coupling agent KH560 and 30 g of tetrabutylammonium bromide to it, Stir and react at 116°C for 7 hours, then wash with water for 7 times, then use anhydrous magnesium sulfate to remove water, filter and spin evaporate at 57°C to remove the solvent;

[0037] The preparation method of described modified epoxy-terminated nitrile rubber comprises the steps of: adding 40 g of epoxy-terminated nitrile rubber in 135 g of dichloromethane, and adding 1,3,5,7-tetrakis (4 -Aminophenyl)adamantane 10g, stirred and reacted at 72°C for 7.2 hours, and then removed the solvent by rotary evaporation at 56°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com