High-activity functional diatom mud and preparation method thereof

A functional, diatom mud technology, applied in separation methods, chemical instruments and methods, climate sustainability, etc., can solve problems such as insufficient hardness, waste of resources, and increased production costs, and can solve the problems of insufficient hardness, powder loss, resource loss, etc. Not to be wasted, to ensure the effect of reasonable utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

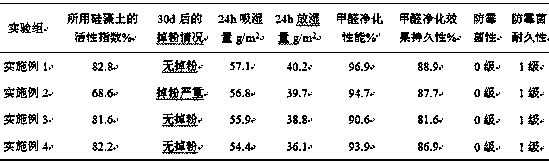

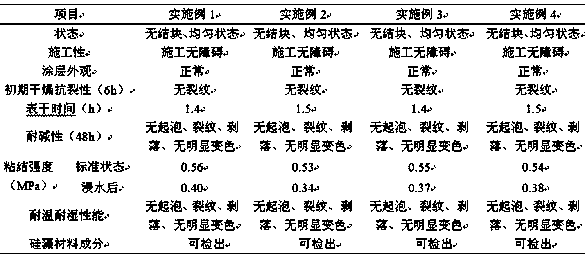

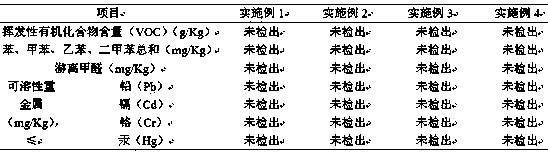

Examples

Embodiment 1

[0014] 1) Add 150 mesh of second and third grade diatomite to 60% sulfuric acid for acid leaching for 3 hours and then place it in a high temperature furnace. The anaerobic heat activation temperature is 600°C and the heat activation time is 2 hours. After cooling to room temperature, it will be activated. After the diatomaceous earth;

[0015] 2) After mixing 20mol of zinc nitrate and 1mol of citric acid, add 200mol of distilled water. Stir it evenly, and at the same time slowly drop in 20mol of absolute ethanol, then slowly drop in 2mol of ammonia water, then add 0.05mol of polyethylene glycol, and then ultrasonically treat for 60min, then put it in 80℃ water temperature Stir with magnetic flow for 5 h to obtain a suspension; mix the activated diatomaceous earth with the suspension at a molar ratio of 4:1. Mix evenly, let stand for 1 hour, dry, grind, and calcinate in a high-temperature furnace at 600°C for 2 hours to obtain diatomite / nanometer zinc oxide composite photocat...

Embodiment 2

[0018] This embodiment selects the diatomite on the market to prepare diatom ooze, is blank control group

[0019] 1) Select diatomite (calcined at a temperature above 1000°C) commonly used in the market as the functional filler;

[0020] 2) After mixing 25mol of zinc nitrate and 1mol of citric acid, add 230mol of distilled water. Stir it evenly, and at the same time slowly drop in 30mol of absolute ethanol, then slowly drop in 5mol of ammonia water, then add 0.03mol of polyethylene glycol, and then ultrasonically treat for 60min, then put it in 80℃ water temperature Stir with magnetic current for 2 hours to obtain a suspension; mix the activated diatomaceous earth with the suspension at a molar ratio of 6:1. Mix evenly, let stand for 4 hours, dry, grind, and calcinate in a high-temperature furnace at 600°C for 2 hours to obtain diatomite / nanometer zinc oxide composite photocatalytic material powder;

[0021] 3) Combine 25kg of the diatomite / nanometer zinc oxide composite ph...

Embodiment 3

[0023] In this example, the diatomaceous earth loaded with nano-zinc oxide in the common method is used to prepare diatom ooze

[0024] 1) Add 180-mesh diatomite to 40% sulfuric acid for pickling for 2 hours and place it in a high-temperature furnace. The anaerobic heat activation temperature is 600 ° C, and the heat activation time is 2 hours. After cooling to room temperature, it will be activated. After the diatomaceous earth;

[0025] 2) After mixing 25mol of zinc nitrate and 1mol of citric acid, add 280mol of distilled water. Stir it evenly, and at the same time slowly drop in 40mol of absolute ethanol, then slowly drop in 3mol of ammonia water, then add 0.05mol of polyethylene glycol, and then ultrasonically treat for 60min, then put it in 100℃ water temperature Stir with magnetic flow for 2 h to obtain a suspension; mix the activated diatomaceous earth with the suspension at a molar ratio of 5:1. Mix evenly, stand still for 5 hours, dry, grind, and calcinate in a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com