High-elasticity flame-retardant floor mat and preparation method thereof

A floor mat and high-elasticity technology, which is applied in the field of high-elastic flame-retardant floor mats and its preparation, to achieve the effects of reducing trauma, simple preparation process, and improving high-elastic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

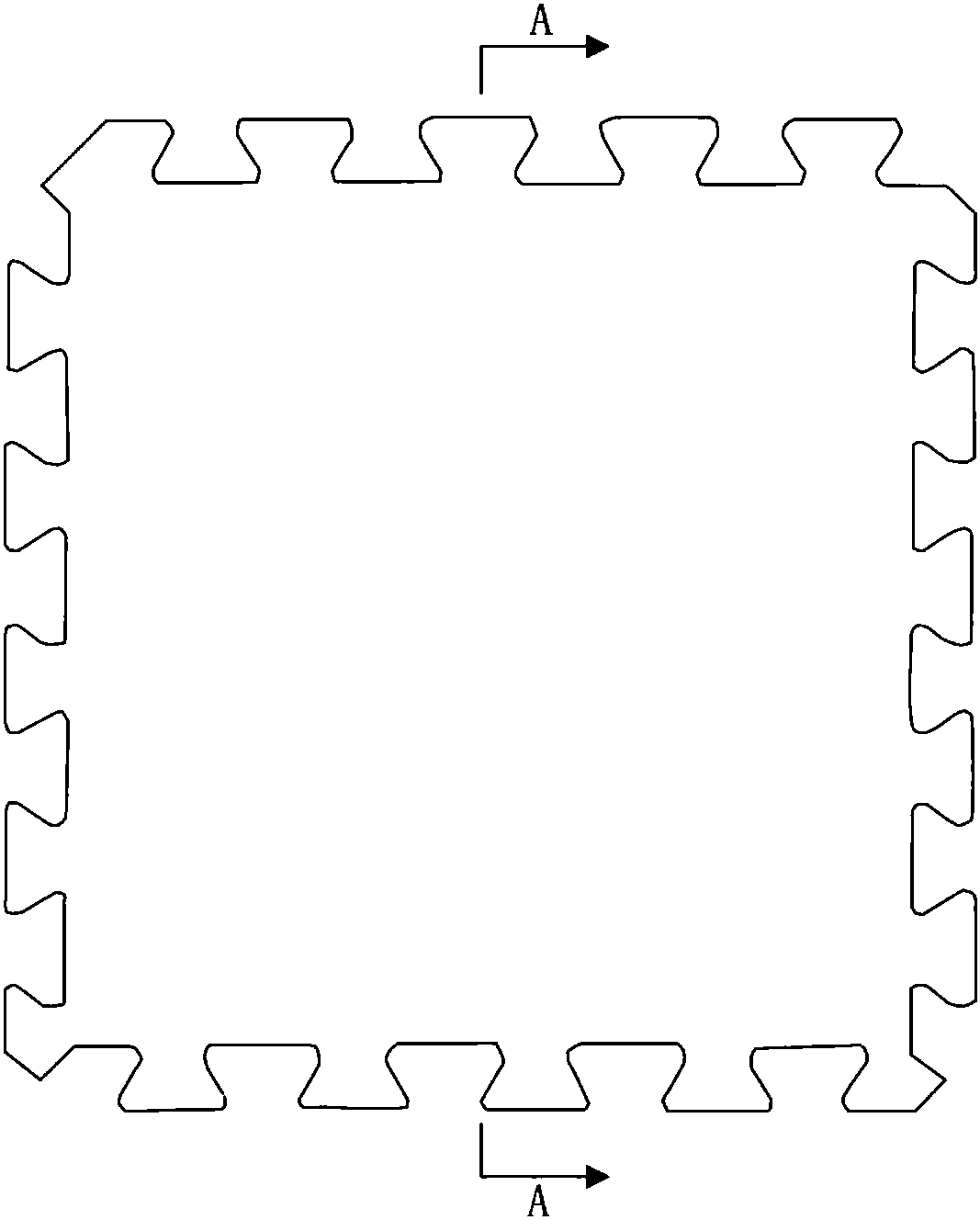

Image

Examples

Embodiment 1

[0034] The preparation method of the high-elasticity flame-retardant floor mat comprises the following steps:

[0035] (1) Preparation of foamed plastic layer

[0036] Weigh the following raw materials by weight: 90 parts of polyvinyl chloride, 69 parts of ethylene-vinyl acetate copolymer, 70 parts of phenolic resin, 30 parts of EVA toughening resin and 21 parts of peroxylauroyl, 75 parts of plasticizer, 17 parts of foaming agent, 13 parts of flame retardant and 6 parts of color masterbatch;

[0037] The above-mentioned polyvinyl chloride, ethylene-vinyl acetate copolymer, phenolic resin, EVA toughening resin and peroxylauroyl peroxide are added in the mixer and stirred, and the mixture is uniformly stirred to form a thin paste;

[0038] Add uniformly mixed color masterbatch, plasticizer and foaming agent mixture to the thin paste mixture, control the stirring speed at 500-800r / min, and stir for 20min to obtain a paste mixture;

[0039] Send the paste mixture into the scrape...

Embodiment 2

[0049] The preparation method of the high-elasticity flame-retardant floor mat comprises the following steps:

[0050] (1) Preparation of foamed plastic layer

[0051] Weigh the following raw materials by weight: 100 parts of polyvinyl chloride, 90 parts of ethylene-vinyl acetate copolymer, 80 parts of phenolic resin, 55 parts of EVA toughening resin, 35 parts of peroxylauroyl, 90 parts of plasticizer, 25 parts of foaming agent, 28 parts of flame retardant and 8 parts of color masterbatch;

[0052] The above-mentioned polyvinyl chloride, ethylene-vinyl acetate copolymer, phenolic resin, EVA toughening resin and peroxylauroyl peroxide are added in the mixer and stirred, and the mixture is uniformly stirred to form a thin paste;

[0053] Add uniformly mixed color masterbatch, plasticizer and foaming agent mixture to the thin paste mixture, control the stirring speed at 800r / min, and stir for 20min to obtain a paste mixture;

[0054] The paste mixture was sent into the scraper ...

Embodiment 3

[0064] The preparation method of the high-elasticity flame-retardant floor mat comprises the following steps:

[0065] (1) Preparation of foamed plastic layer

[0066] Weigh the following raw materials by weight: 80 parts of polyvinyl chloride, 55 parts of ethylene-vinyl acetate copolymer, 75 parts of phenolic resin, 40 parts of EVA toughening resin, 35 parts of peroxylauroyl, 85 parts of plasticizer, 21 parts of foaming agent, 23 parts of flame retardant and 7 parts of color masterbatch;

[0067] The above-mentioned polyvinyl chloride, ethylene-vinyl acetate copolymer, phenolic resin, EVA toughening resin and peroxylauroyl peroxide are added in the mixer and stirred, and the mixture is uniformly stirred to form a thin paste;

[0068] Add uniformly mixed color masterbatch, plasticizer and foaming agent mixture to the thin paste mixture, control the stirring speed at 500r / min, and stir for 20min to obtain a paste mixture;

[0069] The paste mixture was sent into the scraper c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com