Formula for metal borophosphate ammonium salt flame-retardant and smoke-suppressing wood-plastic composite material

A wood-plastic composite material and ammonium borophosphate technology are applied in the field of metal ammonium borophosphate fire-retardant and smoke-suppressing wood-plastic composite material formulation, which can solve the problem of adding a large amount of flame retardant, affecting the mechanical properties of wood-plastic materials, and preventing flame retardant. The problem of low smoke suppression efficiency, etc., achieves the effects of low addition amount, excellent adsorption effect, and high flame retardant and smoke suppression efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

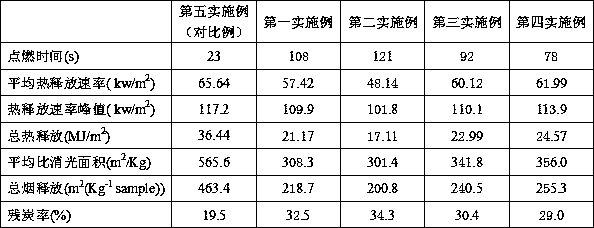

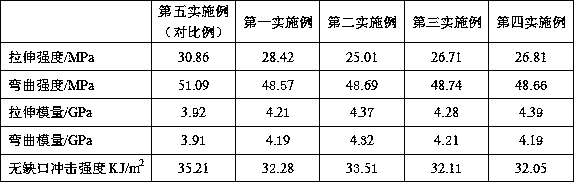

[0017] Below in conjunction with embodiment the present invention will be further described, but the present invention is not limited to these examples, under the premise of departing from the gist of the present invention, any improvement made falls within the protection scope of the present invention.

[0018] According to the invention, a metal borophosphate ammonium salt flame-retardant and smoke-suppressing wood-plastic composite material formula is made of the following raw materials in parts by weight: 100-300 parts of thermoplastic, 100-600 parts of wood fiber, and 0-6 parts of stabilizer , 0.75-20 parts of lubricant, 4.5-80 parts of coupling agent, 5-15 parts of flame retardant and smoke suppressant of metal borophosphate ammonium salt.

[0019] Further, the thermoplastics are polyethylene, polypropylene, polystyrene and polyvinyl chloride thermoplastic resins or waste plastics, which are formed by mixing the above-mentioned one kind of plastics, or the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com