Nonaqueous electrolyte secondary battery, method for manufacturing nonaqueous electrolyte secondary battery

A non-aqueous electrolyte and secondary battery technology, which is applied in the direction of non-aqueous electrolyte battery electrodes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., and can solve the problems that cannot be applied unchanged as it is

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] [Preparation of non-aqueous electrolyte solution]

[0060] In a mixed solvent composed of 30% by volume of ethylene carbonate (EC), 30% by volume of ethylmethyl carbonate (EMC) and 40% by volume of dimethyl carbonate (DMC) as the nonaqueous solvent of the nonaqueous electrolytic solution, Add LiPF in a way to reach 1mol / L 6 They are mixed as an electrolyte salt, and then 3.0 to 3.75% by mass of cyclohexylbenzene is added to the mixed solvent and mixed to prepare an electrolytic solution.

[0061] [Creation of conductive path]

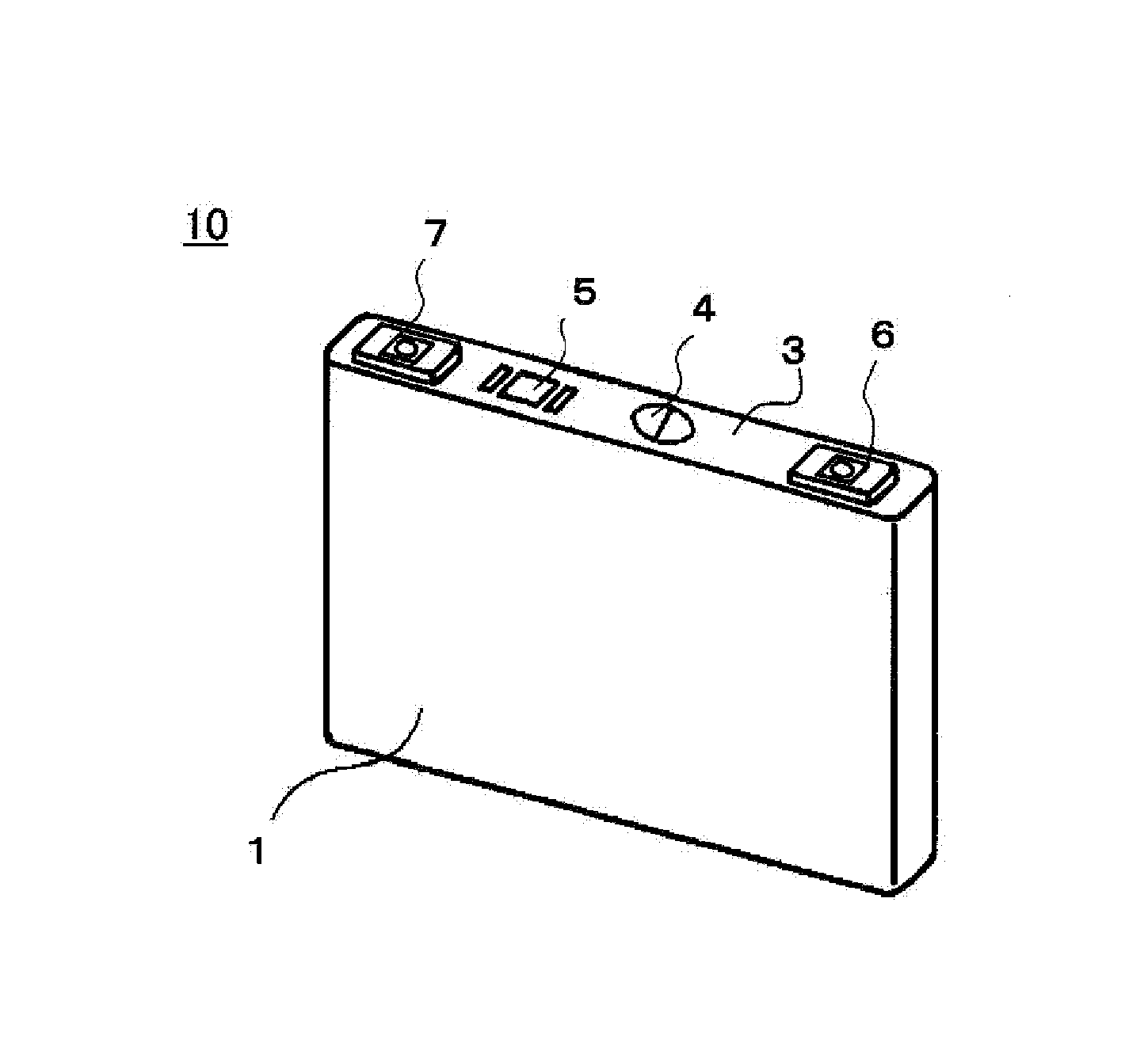

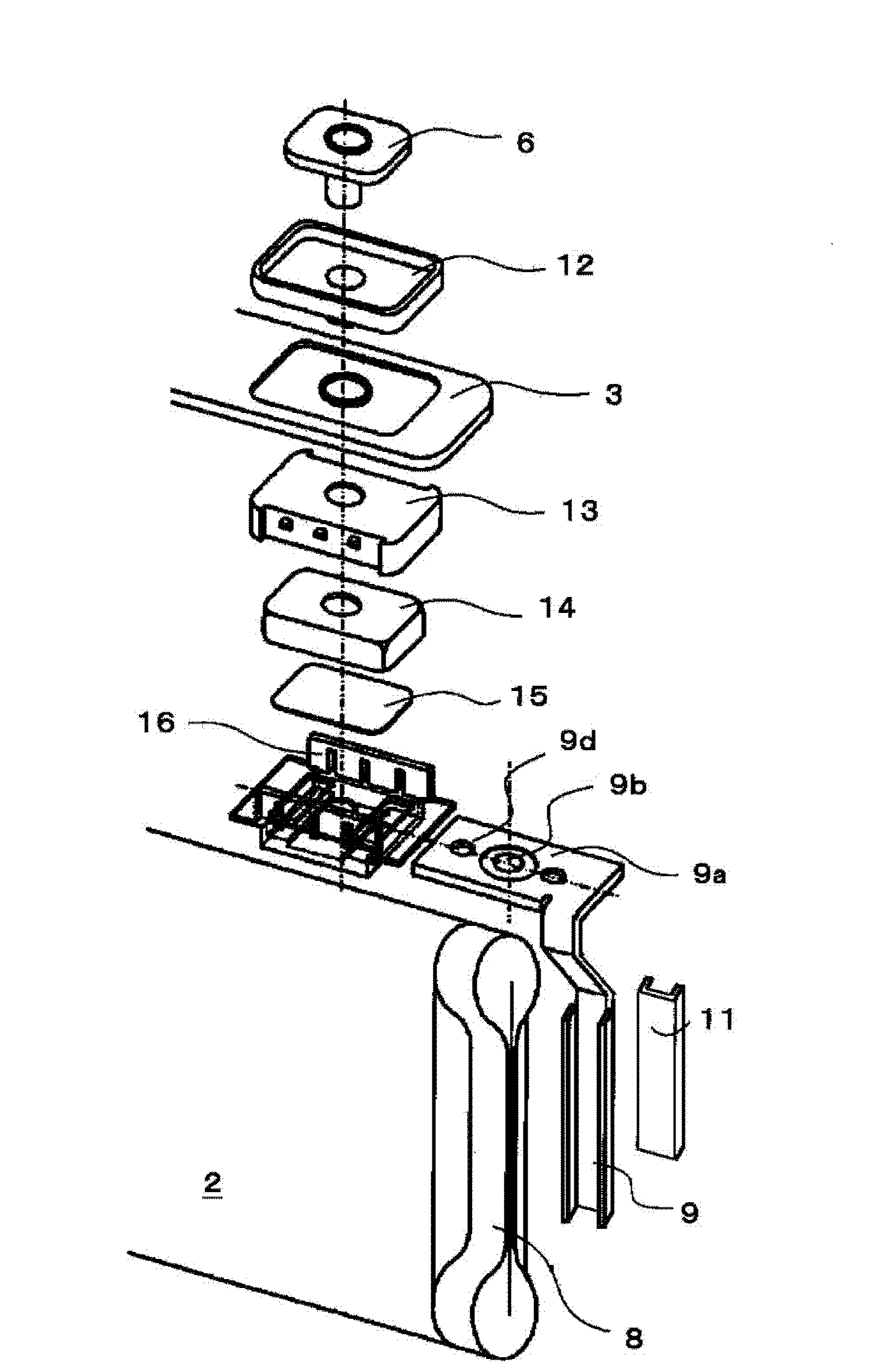

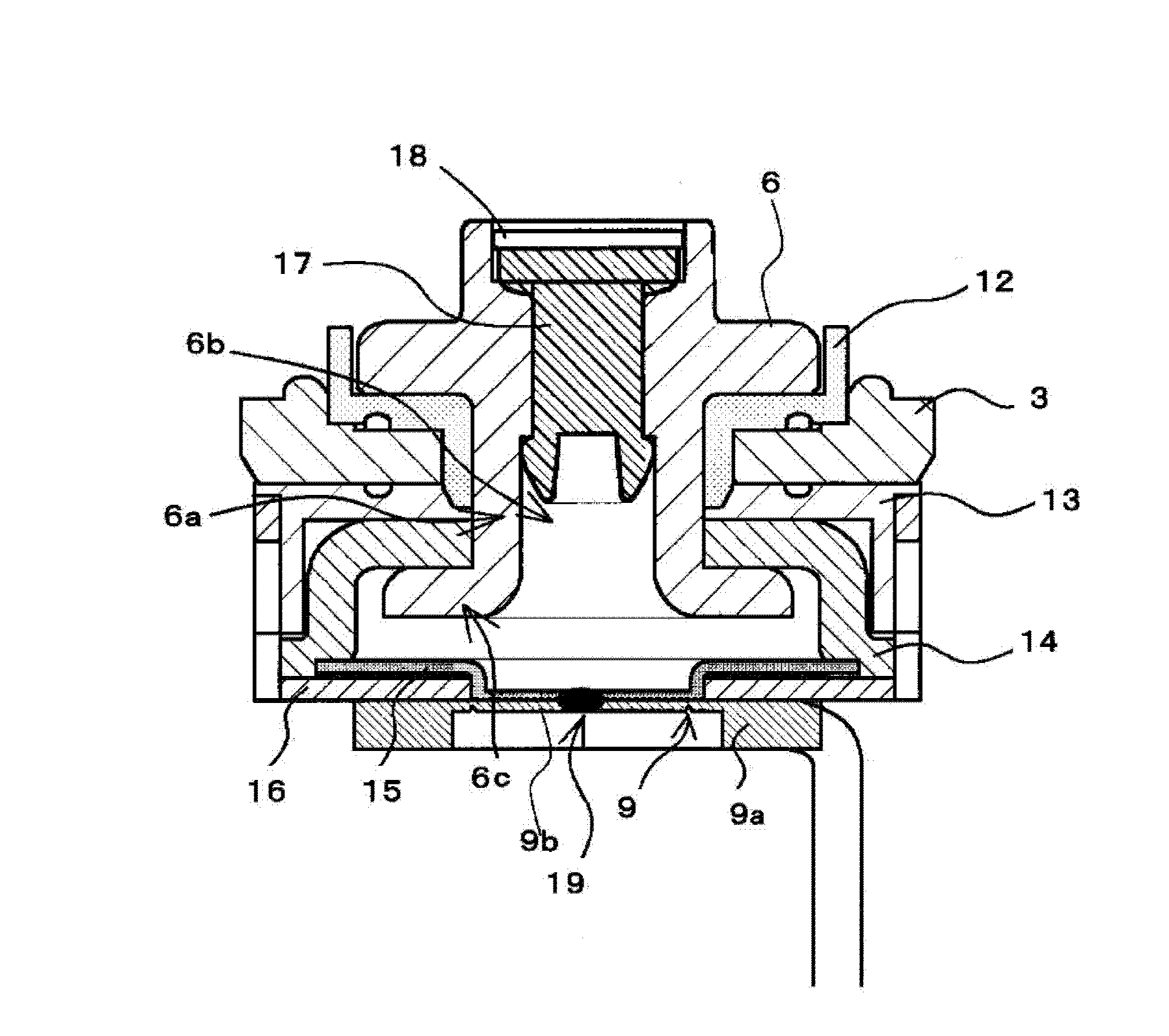

[0062] A description will be given of a procedure for fabricating a conductive path on the positive electrode side provided with a current blocking mechanism. First, resin gaskets 12 are arranged on the upper surface of the sealing plate 3 made of aluminum, and insulating members 13 made of resin and conductive members 14 made of aluminum are arranged on the lower surface of the sealing plate 3. The cylindrical portion 6a of the positive elect...

Embodiment 1

[0071] The non-aqueous electrolytic solution prepared as described above is made so that the amount of cyclohexylbenzene present inside the outer packaging body is 2.85 g / m with respect to the formation area of the positive electrode active material layer in the positive electrode core surface 2 The method is to inject from the liquid injection hole provided in the sealing body, and then seal the liquid injection hole with a blind rivet. Thereafter, charge with a constant current of 25A to a given voltage, and after reaching the given voltage, carry out constant voltage charging at this voltage, charge until the termination current is 0.25A, and set the battery's depth of charge (SOC) to 60%. Thereafter, an aging treatment at 75° C. for 22 hours was performed to manufacture the prismatic lithium ion secondary battery of Example 1. And, the sum of the regions where the positive electrode active material layer is formed in the front and back of the positive electrode core is s...

Embodiment 2

[0073] Except that the non-aqueous electrolytic solution prepared as described above is made so that the amount of cyclohexylbenzene present inside the outer packaging body is 3.06 g / m with respect to the formation area of the positive electrode active material layer in the surface of the positive electrode core body 2 The prismatic lithium-ion secondary battery of Example 2 was produced in the same manner as in Example 1, except that it was injected from the liquid injection hole provided in the sealing body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com