Monolithic oxidation catalyst for VOCs and preparation method of oxidation catalyst

An oxidation catalyst, integrated technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve the problem of affecting performance, large heat capacity, reducing catalyst performance, etc. problems, to achieve the effects of improving stability and durability, optimizing the preparation process, and excellent treatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

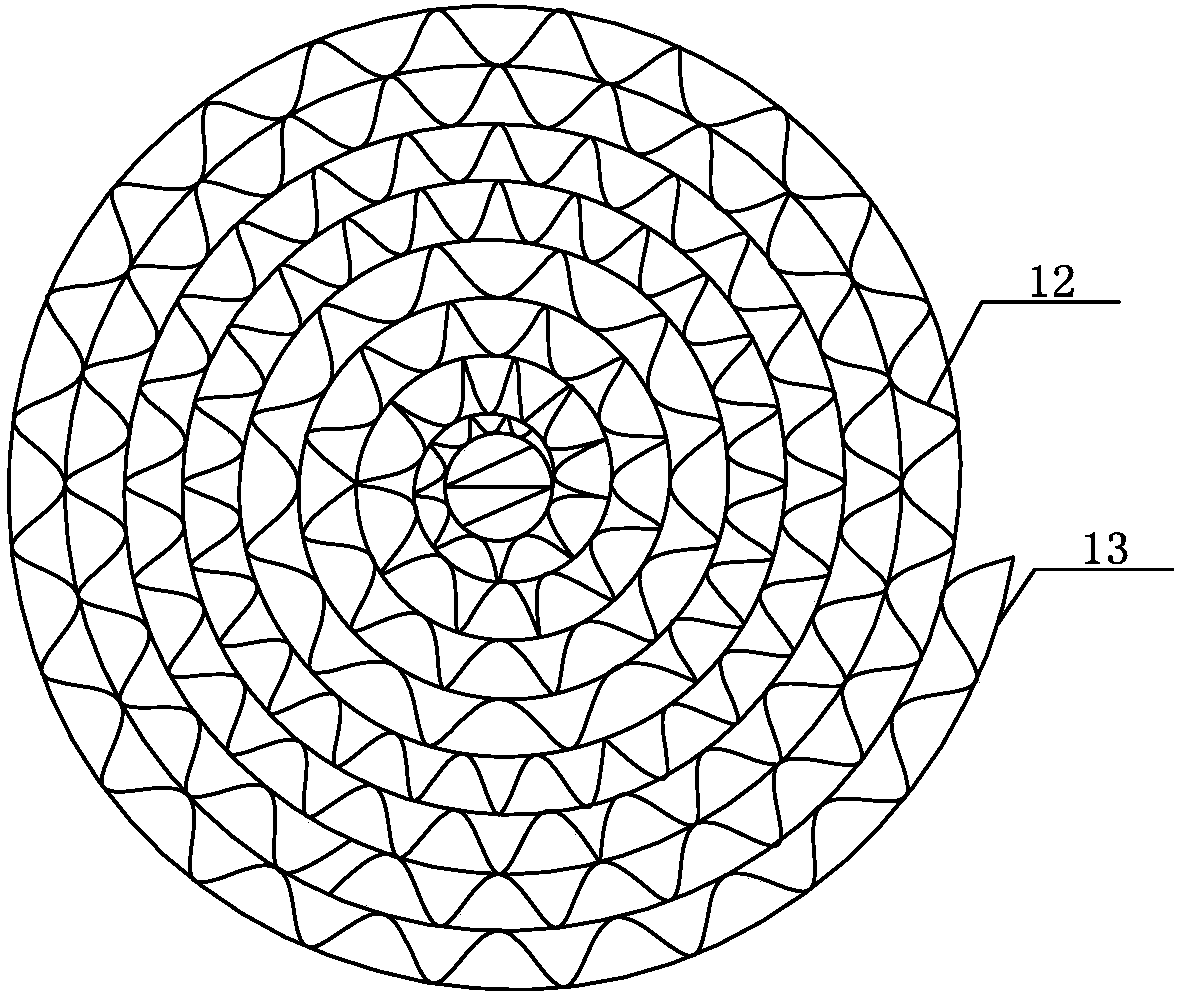

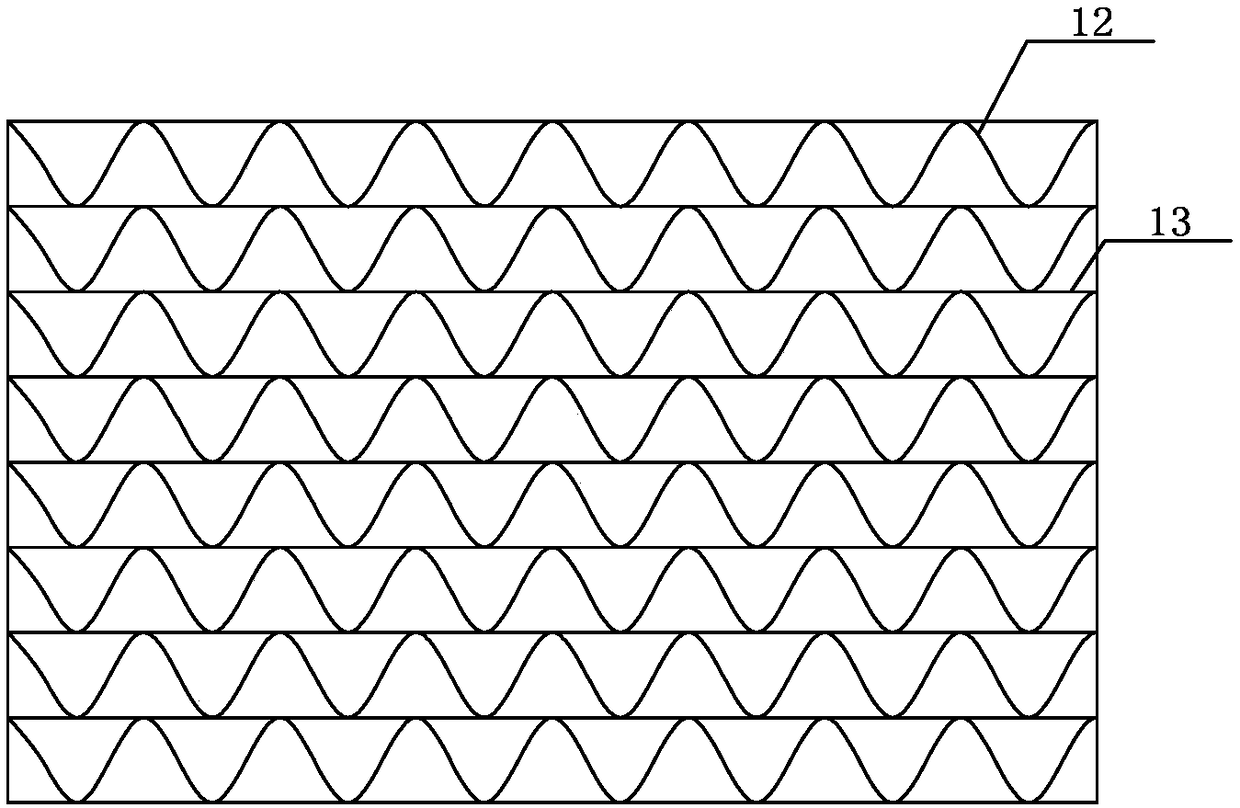

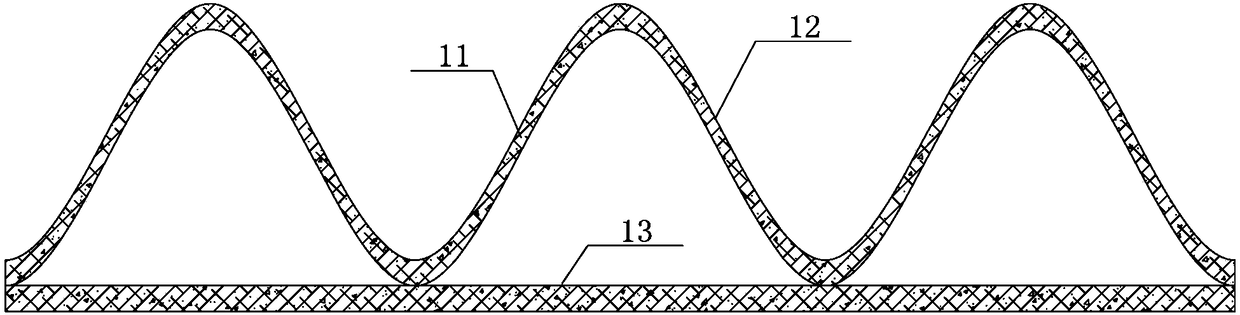

[0044] Carrier: integral carrier of ceramic fiber substrate, inch

[0045] 0.45g Na 2 CO 3 Mix with 290mL of deionized water, add 2.4g of PEG and 24g of aluminum sol (20wt%), and stir to obtain a mixed solution. Add 86.8g active Al successively 2 o 3 , 24.8g cerium-zirconium oxygen storage material, 6.2g La 2 o 3 and 6.2g Y 2 o 3 , stirred well and with HNO 3 Adjust pH=3-4, add 4g Pd(NO 3 ) 2 Continue ball milling for 1 h to obtain coating slurry.

[0046] The slurry is coated on the carrier by a vacuum coating machine, coated for 2-3 minutes and vacuum purged, dried with hot air at 120° C. for 30 minutes, and calcined in an air atmosphere at 500° C. for 4 hours to obtain a monolithic VOCs oxidation catalyst. The coating amount of the coating layer on the catalyst was 123 g / L, and the loading amount of the noble metal was 0.61 g / L Pd.

Embodiment 2

[0048] Carrier: integral carrier of ceramic fiber substrate, inch

[0049] 0.39g Na 2 CO 3 Mix with 290mL of deionized water, add 1.8g of PEG and 18g of aluminum sol (20wt%), and stir to obtain a mixed solution.

[0050] Add 86.8g active Al successively 2 o 3 , 24.8g cerium-zirconium oxygen storage material, 6.2g La 2 o 3 and 6.2g Y 2 o 3 , stirred well and with HNO 3 Adjust pH=3-4, add 2.8g Pd(NO 3 ) 2 and 1.2g Pt(NO 3 ) 2 , continue ball milling for 1 h to obtain coating slurry.

[0051] The slurry is coated on the carrier by a vacuum coating machine, coated for 2-3 minutes and vacuum purged, dried with hot air at 120° C. for 30 minutes, and calcined in an air atmosphere at 500° C. for 4 hours to obtain a monolithic VOCs oxidation catalyst. The coating weight of the coating on the catalyst was 128 g / L, and the noble metal loadings were 0.44 g / L Pd and 0.18 g / L Pt.

Embodiment 3

[0053] Carrier: glass fiber substrate monolithic carrier, inch

[0054] 0.52g Na 2 CO 3 , 24.96g Mn(NO 3 ) 2 Mix with 290mL of deionized water, add 1.8g of PEG and 6g of pseudo-boehmite, and stir to obtain a mixed solution. Add 24.8g active Al successively 2 o 3 , 86.8g cerium-zirconium oxygen storage material, 6.2g La 2 o 3 and 6.2gY 2 o 3 , stirred well and with HNO 3 Regulate pH=3-4, add 2.8g Pd(NO 3 ) 2 and 1.2g Pt(NO 3 ) 2 , continue ball milling for 1 h to obtain coating slurry.

[0055] The slurry is coated on the carrier by a vacuum coating machine, coated for 2-3 minutes and vacuum purged, dried with hot air at 120° C. for 30 minutes, and calcined in an air atmosphere at 500° C. for 4 hours to obtain a monolithic VOCs oxidation catalyst. The coating amount of the coating on the catalyst is 134g / L, and MnO in the coating 2 The loading is 5wt%, and the noble metal loading is 0.47g / L Pd and 0.2g / L Pt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com