Deoxygenation device and deoxygenation method for polymer solution

A polymer solution and glass catheter technology, applied in separation methods, chemical instruments and methods, liquid degassing, etc., can solve problems such as high oxygen content, hindering oxygen precipitation, high viscosity, etc., and achieve high oxygen removal efficiency and easy operation Convenient and thorough oxygen removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

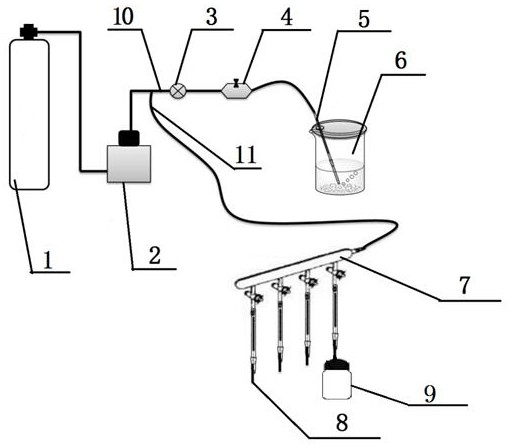

[0030] Embodiment 1 A kind of deoxygenation device of polymer solution

[0031] Including: gas source cylinder (1), buffer bottle (2), ball valve (3), gas flow meter (4), glass catheter (5), reagent bottle (6), gas distributor (7), puncture needle ( 8), narrow mouth glass bottle (9);

[0032] The gas source steel cylinder (1) is connected with the buffer bottle (2) through a rubber conduit, and the outlet of the buffer bottle (2) has two nozzles, namely the first nozzle (10) and the second nozzle ( 11);

[0033] Described first mouthpiece (10) connects an end of glass conduit (5) by silica gel tube; The other end of described glass conduit (5) is inserted in the reagent bottle (6); The described reagent bottle (6) The bottle mouth is sealed with a plastic film, and only vent holes are left at the glass conduit (5); the described spherical valve (3) and the gas flowmeter (4) are installed on the silicone tube before the glass conduit (5) successively;

[0034] The second noz...

Embodiment 2

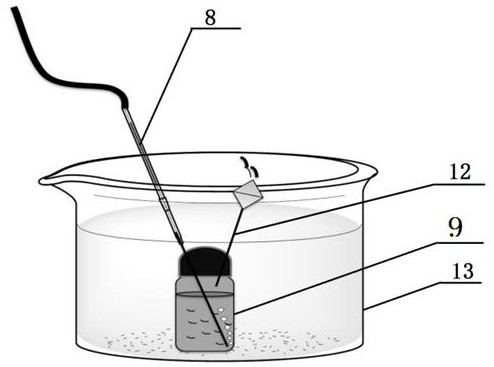

[0035] Embodiment 2 The insertion method and water bath method of the puncture needle on the narrow mouth bottle

[0036] The insertion method and water bath method of the puncture needle used in embodiment 1 on the narrow-mouth bottle are: the puncture needle (8) is inserted into the bottom of the narrow-mouth glass bottle (9) of the polymer solution after step S1 treatment is housed, and then Another puncture needle (12) is inserted above the liquid surface of the narrow-mouth glass bottle, and the whole bottle of the narrow-mouth glass bottle is immersed in the water bath cup to carry out water bath sealing.

Embodiment 3

[0037] Embodiment 3 A kind of oxygen removal method of the oxygen removal device of polymer solution

[0038] The oxygen removal method of the oxygen removal device using the polymer solution of Example 1 includes the following steps: S1 initial stage oxygen removal: at room temperature, the polymer solution is added to the reagent bottle, the gas source steel cylinder and the ball valve are opened, and the gas is passed through the glass catheter Pass inert gas into the bottom of the reagent bottle containing the polymer solution, the rate of passing inert gas is 0.2L / min; the time of ventilation is 1h, divide the treated polymer solution into narrow-mouthed glass bottles, and use rubber The plug and the aluminum cover are sealed in turn, and stored in a normal temperature water bath for later use;

[0039] S2 deep deoxygenation: at room temperature, open the gas source steel cylinder and the valve on the gas distributor in turn to blow out the inert gas from the puncture nee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com