High-transparent ultraviolet-blocking energy-saving membrane and solution phase transfer preparation method

A technology of energy-saving film and transparent violet, which is applied in the field of highly transparent UV-blocking energy-saving film and its preparation, can solve the problems of reducing the service life of the film, yellowing, etc., and achieve the effects of low production cost, small environmental pollution, and remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

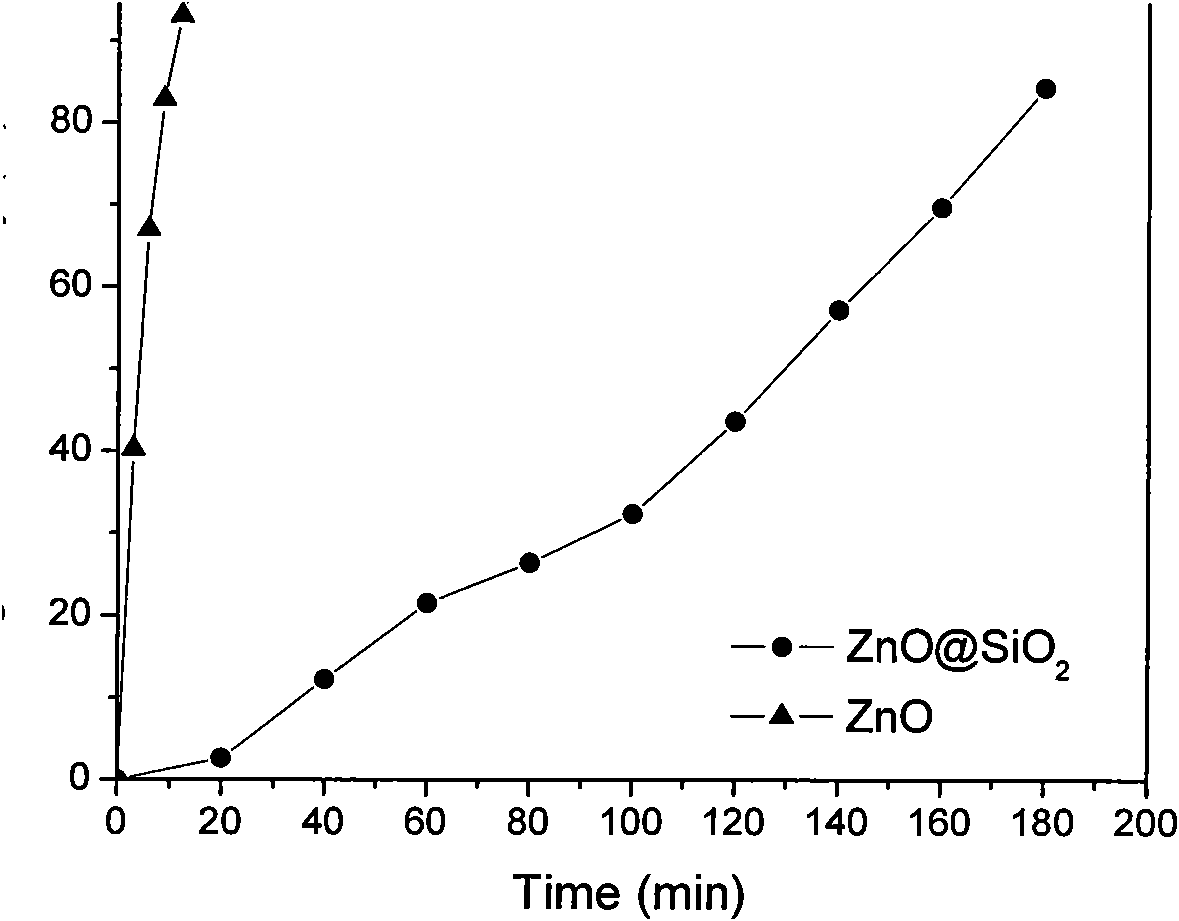

Embodiment 1

[0048] 1) The initial dispersion system of methanol solution of zinc oxide nanoparticles with core-shell structure, after centrifugation and washing, is transferred to absolute ethanol, and magnetically stirred and ultrasonically dispersed to form ethanol dispersion of zinc oxide nanoparticles with core-shell structure liquid; the concentration of the core-shell structure zinc oxide nanoparticles in the dispersion is 5.88wt%, in the shape of a long rod with a diameter of about 50nm;

[0049] 2) Take 16ml of the dispersion in step 1), add 4ml of absolute ethanol, and mix evenly with magnetic stirring. After ultrasonic treatment for 4 hours, add 0.8g PVB powder, mix evenly with magnetic stirring, and ultrasonically disperse for 0.5h to prepare the film-making stock solution . The obtained film-making stock solution system is shown in Table 1-1;

[0050]

[0051] Table 1-1

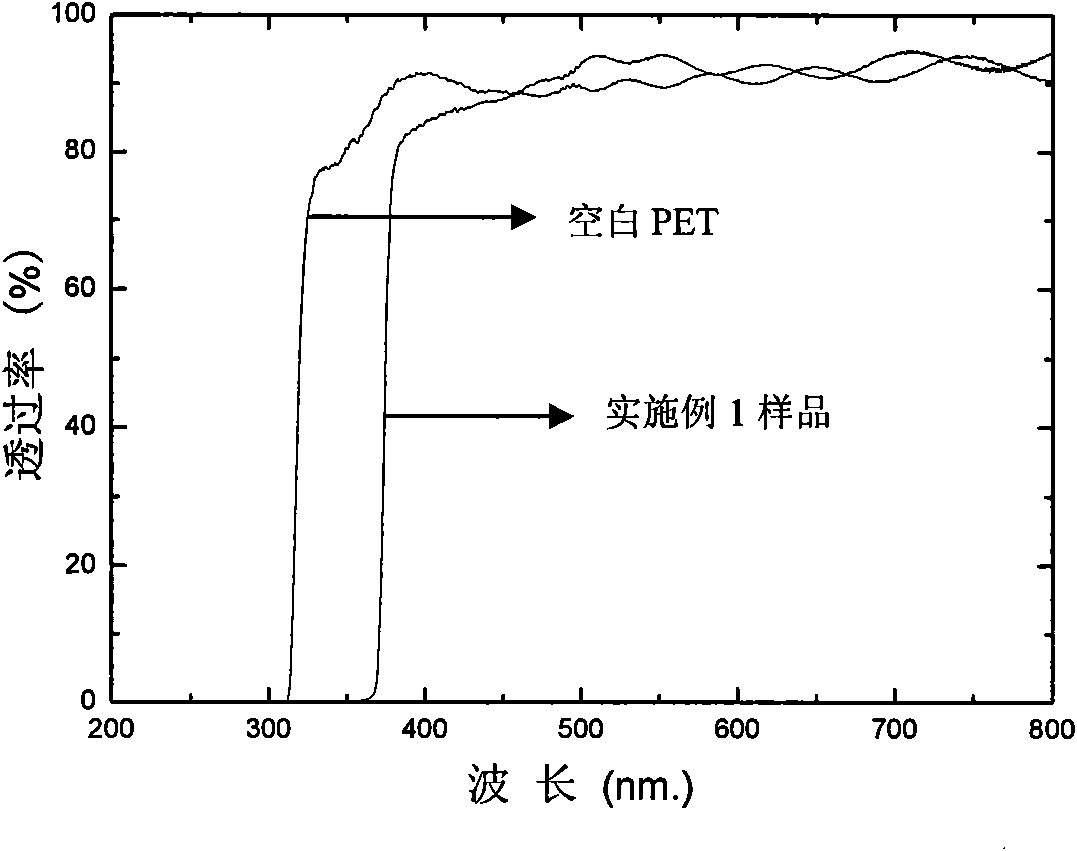

[0052] 3) Select the PET substrate for film formation: after the PET substrate is pretreated with de...

Embodiment 2

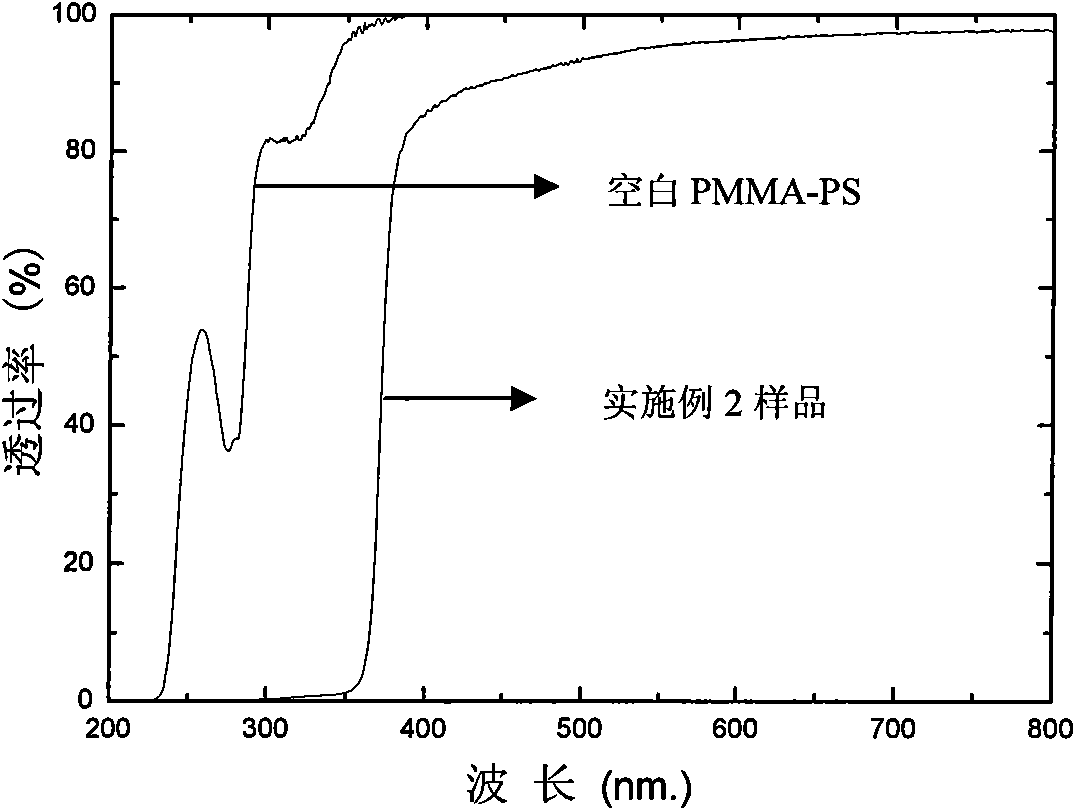

[0056] 1) Centrifuge and wash the initial dispersion system of ZnO nanoparticles with core-shell structure in n-hexane, then transfer it to toluene, and ultrasonically disperse to make a toluene dispersion of core-shell structure ZnO nanoparticles. The core-shell structure in the dispersion is Zinc oxide nanoparticles with a concentration of 5wt% are spherical in shape with a particle size of 10-20nm;

[0057] 2) Take toluene, PMMA-PS copolymer, and the core-shell structure zinc oxide nanoparticle toluene dispersion in step 1) respectively according to the ratio of Table 2-1, and magnetically stir and ultrasonically disperse and mix evenly to obtain the film-making stock solution ;

[0058]

[0059] table 2-1

[0060] 3) Casting the film-forming stock solution obtained in step 2) into a mold for direct molding, and the thickness of the obtained film is 300 μm. The optical performance test results are shown in Table 2-2.

[0061]

[0062] Table 2-2

Embodiment 3

[0064] 1) Centrifuge and wash the initial dispersion system of ZnO nanoparticles with core-shell structure in n-hexane, transfer it to ethyl acetate, and disperse it by ultrasonic to make a dispersion liquid of zinc oxide nanoparticles with core-shell structure in ethyl acetate. The concentration of zinc oxide nanoparticles with a core-shell structure is 5wt%, which is spherical and has a particle size of 10-20nm;

[0065] 2) Measure ethyl acetate, AC-PU copolymer, and the core-shell structure zinc oxide nanoparticle ethyl acetate dispersion in step 1) according to the ratio of Table 2-1 respectively, after magnetic stirring, ultrasonic dispersion and mixing , adding the surface-treated indium tin oxide (ITO) ethyl acetate dispersion liquid to the above solution, stirring evenly to obtain the film-making stock solution of ZnO / indium tin oxide (ITO) / AC-PU;

[0066]

[0067] Table 3-1

[0068] 3) Coating the film-forming stock solution obtained in step 2) on a PET substrate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com