Microbial fermented feed for reducing odor of pig manures of black pigs and preparation method thereof

A technology of microbial fermentation and microbial preparation, which is applied in the field of microbial fermented feed and its preparation to reduce the odor of black pig manure, can solve the problem of not fundamentally eliminating odor molecules such as ammonia, the increase of soil nitrate content, and the utilization of nutrients. To achieve the effect of improving intestinal digestive capacity, accelerating growth and fattening, and improving digestive function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

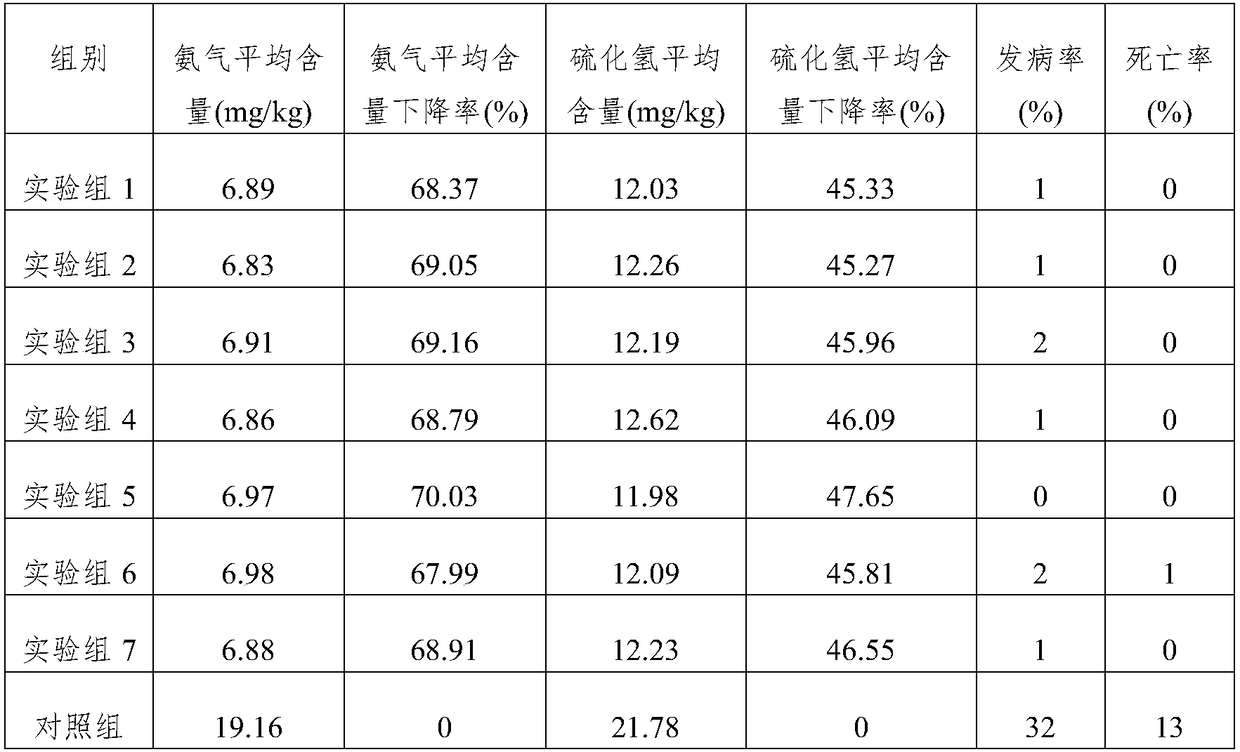

Examples

Embodiment 1

[0028] A microbial fermented feed for reducing the odor of black pig manure, made of the following raw materials in parts by weight: 105 parts of dry lotus root powder, 105 parts of pumpkin powder, 105 parts of potato powder, 100 parts of cassava powder, 100 parts of acorn powder, bran 60 parts of slag, 80 parts of peel, 55 parts of soybean meal, 55 parts of fish meal, 55 parts of bone meal, 55 parts of shellfish powder, 65 parts of crop straw, 85 parts of tea dregs, 85 parts of traditional Chinese medicine dregs, 30 parts of compound enzyme, 45 parts of microbial preparation, Brown sugar 50 parts.

[0029] Further, the microbial preparation is a mixture of Bacillus cereus, yeast, Enterococcus faecalis, nitrifying bacteria, lactic acid bacteria, and Aspergillus oryzae, and their ratio = 1:1:1:1:1:1; the compound The enzyme is a mixture of amylase, cellulase, pectinase, galactase, phytase and protease, and their ratio = 1:2:1:1:1:1; the tea dregs are black tea, green tea , whi...

Embodiment 2

[0035] A microbial fermented feed for reducing the odor of black pig manure, made of the following raw materials in parts by weight: 165 parts of dry lotus root powder, 165 parts of pumpkin powder, 165 parts of potato powder, 160 parts of cassava powder, 160 parts of acorn powder, bran 100 parts of slag, 120 parts of peel, 105 parts of soybean meal, 105 parts of fish meal, 105 parts of bone meal, 105 parts of shellfish powder, 125 parts of crop straw, 125 parts of tea dregs, 125 parts of traditional Chinese medicine dregs, 40 parts of compound enzyme, 55 parts of microbial preparation, 70 parts of brown sugar.

[0036] Further, the microbial preparation is a mixture of Bacillus cereus, yeast, Enterococcus faecalis, nitrifying bacteria, lactic acid bacteria, and Aspergillus oryzae, and their ratio = 1:1:1:1:1:1; the compound The enzyme is a mixture of amylase, cellulase, pectinase, galactase, phytase and protease, and their ratio = 1:3:1:1:1:1; the tea dregs are black tea, gree...

Embodiment 3

[0042] A microbial fermented feed for reducing the odor of black pig manure, made of the following raw materials in parts by weight: 115 parts of dry lotus root powder, 115 parts of pumpkin powder, 115 parts of potato powder, 110 parts of cassava powder, 110 parts of acorn powder, bran 65 parts of slag, 85 parts of fruit peel, 60 parts of soybean meal, 60 parts of fish meal, 60 parts of bone meal, 60 parts of shellfish powder, 75 parts of crop straw, 90 parts of tea dregs, 90 parts of traditional Chinese medicine dregs, 31 parts of compound enzyme, 46 parts of microbial preparation, Brown sugar 52 parts.

[0043] Further, the microbial preparation is a mixture of Bacillus cereus, yeast, Enterococcus faecalis, nitrifying bacteria, lactic acid bacteria, and Aspergillus oryzae, and their ratio = 1:1:1:1:1:1; the compound The enzyme is a mixture of amylase, cellulase, pectinase, galactase, phytase, and protease, and their ratio = 1:2.2:1:1:1:1; the tea dregs are black tea, green t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com