A kind of treatment method of combined drying of strawberries

A processing method and combined drying technology, which are used in the preservation of fruits/vegetables by dehydration, preservation of fruits and vegetables, food science, etc., can solve the problems of loss of volatile aroma substances, sour taste, poor appearance, etc., and reduce the loss of nutrients. , the effect of reducing sugar loss and improving nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

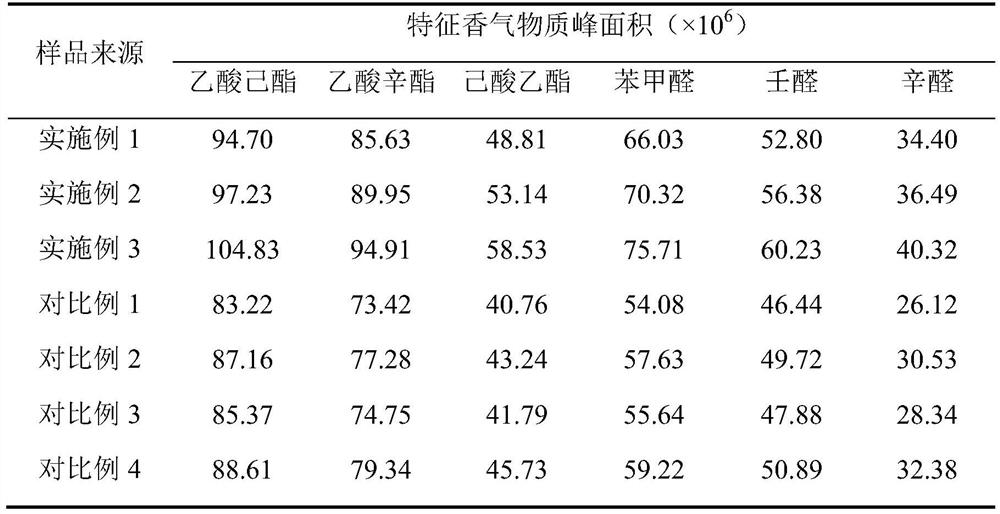

Examples

Embodiment 1

[0024] 1) Choose fresh and undamaged red strawberries that are 8-9 years old, have the same size, and have an acidity pH of 3.8-4.4;

[0025] 2) Remove the stems of the strawberries selected in step 1), clean them, and remove the spoils such as worms, eggs, mud and sand attached to the surface of the strawberries; remove surface debris;

[0026] 3) put the strawberries that have been removed of impurities in step 2) into a compound enzymatic hydrolysis solution of 0.15% cellulase, 0.20% pectinase and 0.10% papain by the quality of the removed strawberries, and enzymolyze at 37° C. for 30 minutes;

[0027] 4) Step-by-step sugaring:

[0028] (1) Put the strawberries enzymatically hydrolyzed in step 3 into an isomalt solution with a mass fraction of 15%, with a solid-to-liquid ratio of 1:10, and use 100w ultrasonic impregnation for 5 minutes,

[0029] (2) Continue to impregnate for 5 minutes under 0.05Mpa vacuum condition,

[0030] (3) Continue to soak for 5 minutes under the u...

Embodiment 2

[0036] Embodiment 2, with embodiment 1, the difference is,

[0037] 3) put the strawberries removed from impurities in step 2) into a compound enzymatic hydrolysis solution of 0.20% cellulase, 0.25% pectinase and 0.15% papain by the quality of the removed strawberries, and perform enzymolysis at 37° C. for 60 minutes;

[0038] 4) Step-by-step sugaring:

[0039] (1) Put the strawberries enzymatically hydrolyzed in step 3 into the isomalt solution with a mass fraction of 20%, the ratio of solid to liquid is 1:20, and use 150w ultrasonic impregnation for 10min,

[0040] (2) Continue to impregnate for 10min under 0.10Mpa vacuum condition,

[0041] (3) Continue to soak for 10 minutes under the ultra-high pressure condition of 300Mpa, then take it out, drain and place it flat on the material tray;

[0042] 6) Put the material plate containing the pre-frozen strawberries in step 5) into the sample rack, insert the eutectic point sensor into the center of the strawberries, cover wit...

Embodiment 3

[0044] Embodiment 3, with embodiment 1, the difference is,

[0045] 3) Put the strawberries removed from impurities in step 2) into a compound enzymatic hydrolysis solution of 0.25% cellulase, 0.30% pectinase and 0.20% papain by the quality of the removed strawberries, and perform enzymolysis at 37° C. for 90 minutes;

[0046] 4) Step-by-step sugaring:

[0047] (1) Put the strawberries enzymatically hydrolyzed in step 3 into an isomalt solution with a mass fraction of 25%, the ratio of solid to liquid is 1:30, and 200w ultrasonic impregnation is used for 15min,

[0048] (2) Continue to impregnate for 15min under 0.15Mpa vacuum condition,

[0049] (3) Continue to soak for 15 minutes under the ultra-high pressure condition of pressure 400Mpa, then take it out, drain and place it flat on the material tray;

[0050] 6) Put the material tray of pre-frozen strawberries in step 5) into the sample rack, insert the eutectic point sensor into the center of the strawberries, cover with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com