Low-shrinkage alkali-activated cementing material and preparation method thereof

A cementitious material, low shrinkage alkali technology, applied in cement production and other directions, can solve the problems of reduced relative humidity, reduced free moisture, large autogenous shrinkage, etc., to reduce early autogenous shrinkage, improve compressive strength, and small autogenous shrinkage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

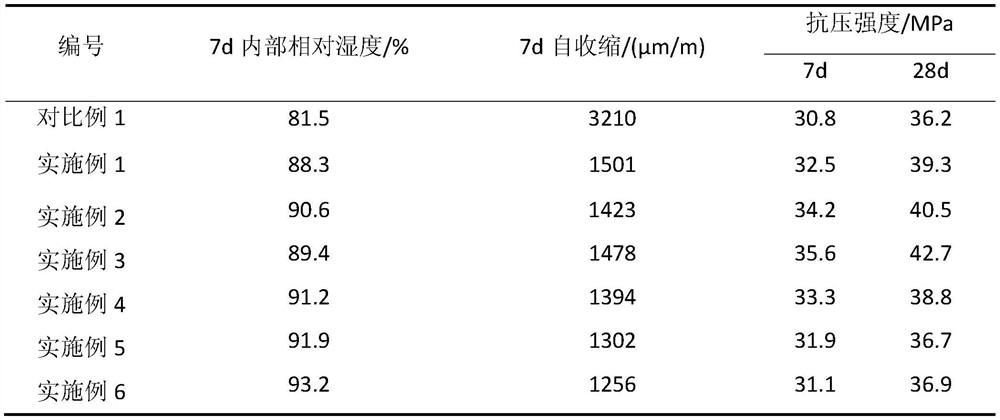

Examples

Embodiment 1

[0027] A low-shrinkage alkali-activated pulp cleaning material, the specific preparation method steps are as follows:

[0028] 1) Take by weight 200 parts of fly ash, 600 parts of mineral powder, biomass incineration ash (rice husk ash, pore size 8-56nm, SiO 2 The content is 87.2%, Na 2 O and K 2 O total content 18%) 200 parts, put into ball mill together and carry out ball milling, make specific surface area reach 0.298m 2 / g, to obtain the gelled material;

[0029] 2) Add 139 parts of alkali activator (obtained by mixing industrial water glass and sodium hydroxide, with a modulus of 1.0), 6 parts of water reducer and 320 parts of water into 1000 parts of gelling material obtained in step 1), the water-binder ratio 0.4, slowly stirred at a speed of 140±5r / min for 30s, then stirred rapidly at a speed of 285±5r / min for 60s to obtain a low-shrinkage alkali-activated cementitious material slurry;

[0030] 3) Place the low-shrinkage alkali-activated gelling material slurry obt...

Embodiment 2

[0032] A low-shrinkage alkali-activated pulp cleaning material, the specific preparation method steps are as follows:

[0033] 1) Take by weight 100 parts of fly ash, 700 parts of mineral powder, biomass incineration ash (peanut shell ash, pore size 5-50nm, SiO 2 The content is 85.3%, Na 2 O and K 2 O total content 18%) 200 parts, put into ball mill together and carry out ball milling, make specific surface area reach 0.312m 2 / g, get the gelling material;

[0034] 2) 139 parts of alkali activators (obtained by mixing industrial water glass and sodium hydroxide, the modulus is 1.0, the dosage of water glass is Na 2 O is calculated as 3% of the amount of gelling material), 7 parts of water reducer and 320 parts of water are added to 1000 parts of gelling material obtained in step 1), the water-binder ratio is 0.4, and the speed is 140 ± 5r / min Stir slowly for 30s , and then stir rapidly at a speed of 285±5r / min for 60s to obtain a low-shrinkage alkali-activated cementitious...

Embodiment 3

[0037] A low-shrinkage alkali-activated pulp cleaning material, the specific preparation method steps are as follows:

[0038] 1) Weigh 100 parts of fly ash, 800 parts of mineral powder, biomass incineration ash (wheat straw ash, pore size 6-52nm, SiO 2 The content is 86.5%, Na 2 O and K 2 O total content 18%) 100 parts, put into ball mill together and carry out ball milling, make specific surface area reach 0.336m 2 / g, to obtain the gelled material;

[0039] 2) 139 parts of alkali activators (obtained by mixing industrial water glass and sodium hydroxide, the modulus is 1.0, the dosage of water glass is Na 2 O is calculated as 3% of the amount of the gelling material), 8 parts of water reducer and 320 parts of water are added to 1000 parts of the gelling material obtained in step 1), the water-binder ratio is 0.4, and slowly stirred at a speed of 140±5r / min for 30s , and then stir rapidly at a speed of 285±5r / min for 60s to obtain a low-shrinkage alkali-activated cementi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com