Coupled adhesive tape

A tape and couplet technology, applied in the direction of adhesives, film/sheet adhesives, etc., can solve the problems of easy adhesion of adhesives to the surface of objects, poor adhesion of adhesives, residual adhesives, etc. , to achieve the effect of retaining the impact response characteristics, improving the microscopic pore structure and increasing the density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

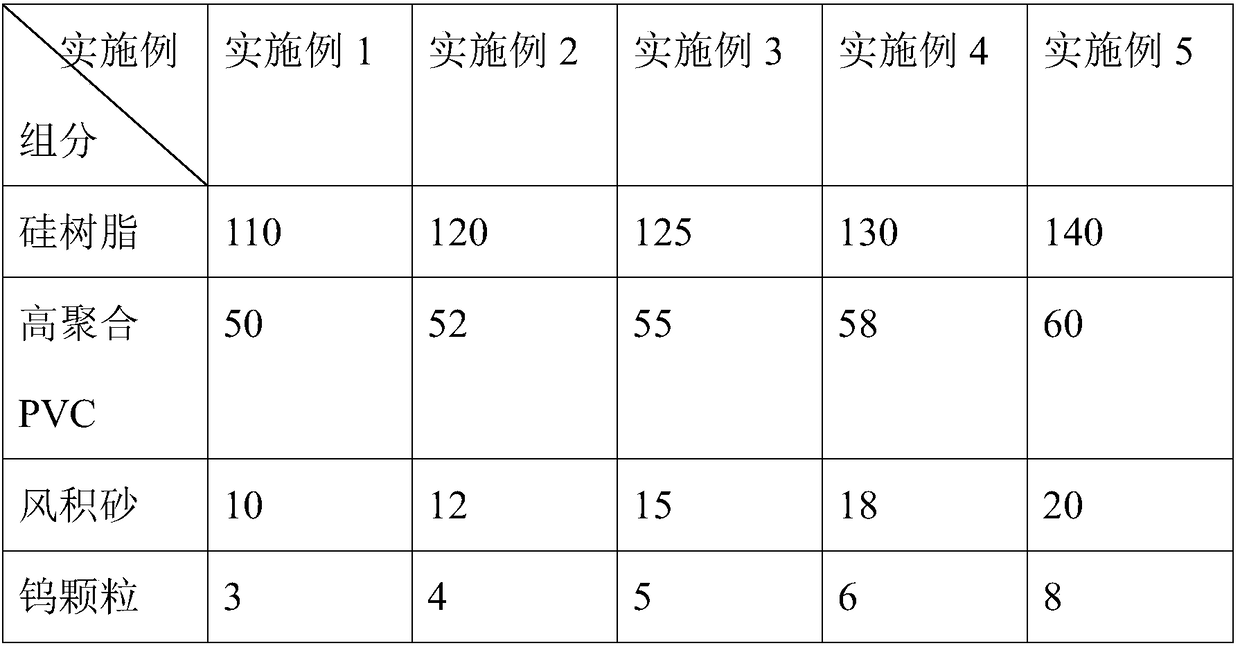

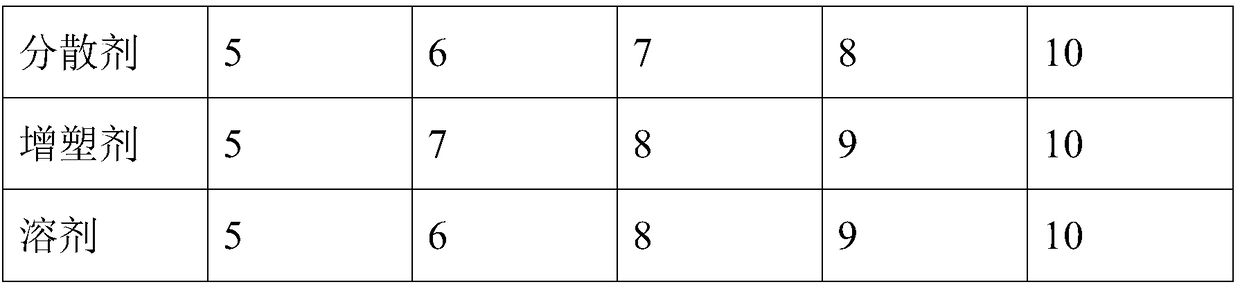

[0028] Reaction synthesis: take silicone resin and PVC according to the antithetical adhesive tape composition in the embodiment 1 of table 1, pour into the solvent and react and discharge; 0.12mm, the particle size of the tungsten particles is 0.25nm, the plasticizer is a mixture of dioctyl adipate and acetyl tributyl citrate, and the mass ratio of the two is 1:1, the reaction The synthesis temperature is 130°C, the time is 2h, and it is carried out under the protection of nitrogen;

[0029] Glue making: add aeolian sand, tungsten particles, dispersant and plasticizer to the discharged solution, stir and mix to obtain rubber;

[0030] Molding: Coat the rubber material on the PET film, cure it in an 80°C constant temperature oven for 2 minutes, cover it with a release film, and bake it in a 40°C constant temperature oven for 2 days to obtain a semi-finished product of the couplet tape base; the thickness of the PET film is 100 μm, the thickness of the release film is 30 μm; ...

Embodiment 2

[0033]Reaction synthesis: take silicone resin and PVC according to the antithetical adhesive tape composition in the embodiment 2 of table 1, pour into the solvent and react and discharge; the degree of polymerization of the high polymer PVC is 2670, and the particle size of the aeolian sand is 0.13mm, the particle size of the tungsten particles is 0.27nm, the plasticizer is a mixture of dioctyl adipate and acetyl tributyl citrate, and the mass ratio of the two is 1.05:1, the reaction The synthesis temperature is 135°C, the time is 2.2h, and it is carried out under the protection of nitrogen;

[0034] Glue making: add aeolian sand, tungsten particles, dispersant and plasticizer to the discharged solution, stir and mix to obtain rubber;

[0035] Molding: Coat the rubber material on the PET film, cure it in a constant temperature oven at 82°C for 2.2 minutes, cover it with a release film, and bake it in a constant temperature oven at 42°C for 2.2 days to obtain a semi-finished p...

Embodiment 3

[0038] Reaction synthesis: take silicone resin and PVC according to the antithetical adhesive tape composition in the embodiment 3 of table 1, pour into the solvent and react and discharge; 0.135mm, the particle size of the tungsten particles is 0.3nm, the plasticizer is a mixture of dioctyl adipate and acetyl tributyl citrate, and the mass ratio of the two is 1.1:1, the reaction The synthesis temperature is 140°C, the time is 2.5h, and it is carried out under the protection of nitrogen;

[0039] Glue making: add aeolian sand, tungsten particles, dispersant and plasticizer to the discharged solution, stir and mix to obtain rubber;

[0040] Molding: Coat the rubber material on the PET film, cure it in a constant temperature oven at 85°C for 2.5 minutes, cover it with a release film, and bake it in a constant temperature oven at 45°C for 2.5 days to obtain a semi-finished product of the couplet tape base; the thickness of the PET film is 110 μm, and the thickness of the release...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com