A concrete admixture for inhibiting transport of erosive media in marine environments

A concrete admixture and marine environment technology, applied in the field of concrete admixtures, can solve the problem of not fundamentally inhibiting the transmission of erosive media, and achieve the effects of inhibiting the transmission of erosive media, reducing electric flux, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

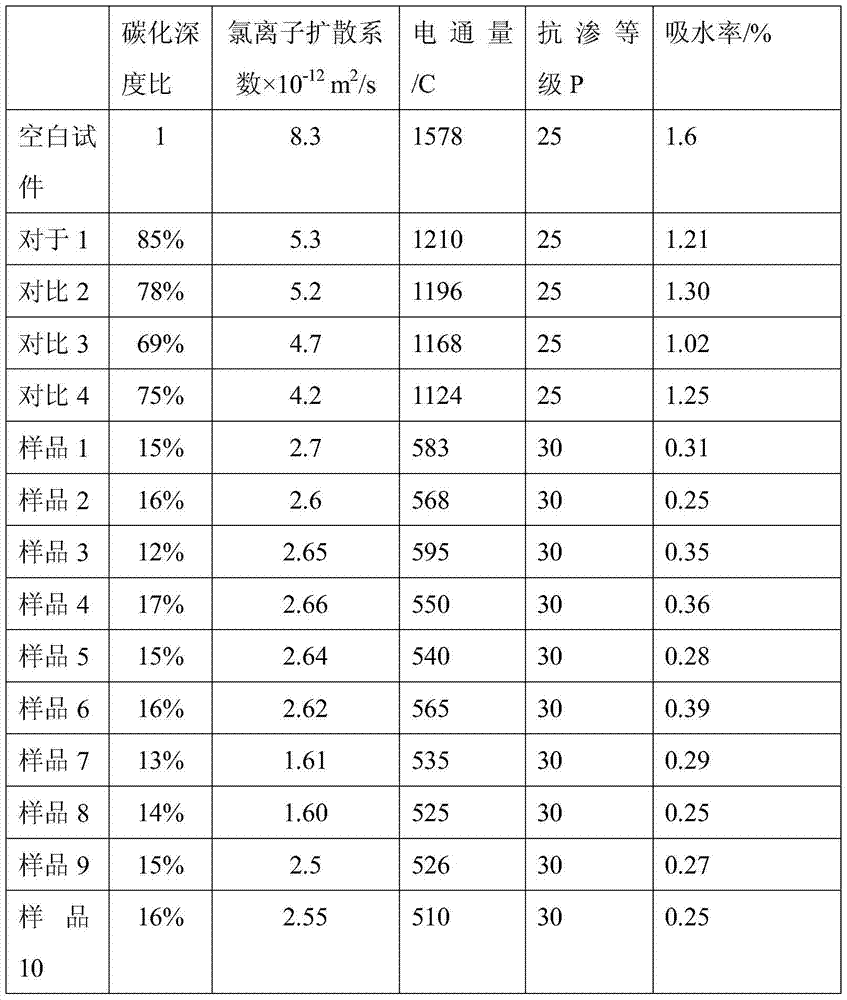

Examples

Embodiment 1

[0029] 1) Preparation of amino-modified polyether polysiloxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 75 g of hydrogen-containing silicone oil, 3 g of allyl glycidyl ether, and 220 g of allyl polysiloxane in sequence. Oxyethylene polyoxypropylene ether, stirred with N2 for 10 minutes, heated up to 90°C, added dropwise a platinum catalyst to react for 4 hours to obtain a polyether / epoxy silicone oil intermediate. Then drop into ethylenediamine at a ratio of 1.05: 1.00 to the epoxy group molar ratio of amine and polyether / epoxy silicone oil intermediate to continue the reaction for 4h. The weight ratio is 8: 2) and the mixed solvent is washed to remove impurities to obtain a viscous liquid.

[0030] 2) Preparation of polypropylmethylsilsesquioxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 140ml of methyltriethoxysilane, 60ml of propyltriethoxysilane, 0.0 1mol / L hydrochloric acid 2...

Embodiment 2

[0033] 1) Preparation of amino-modified polyether polysiloxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 85g of hydrogen-containing silicone oil, 3.5g of allyl glycidyl ether, and 240g of allyl glycidyl ether in sequence. Polyoxyethylene polyoxypropylene ether, stirred with N2 for 10 minutes, heated up to 90°C, added dropwise a platinum catalyst to react for 4 hours to obtain a polyether / epoxy silicone oil intermediate. Then drop into ethylenediamine at a ratio of 1.05: 1.00 to the epoxy molar ratio of amine and polyether / epoxy silicone oil intermediate to continue the reaction for 4h. The weight ratio is 9: 1) and the mixed solvent is washed to remove impurities to obtain a viscous liquid.

[0034] 2) Preparation of polypropylmethylsilsesquioxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 140ml of methyltriethoxysilane, 65ml of propyltriethoxysilane, 0.0 1mol / L hydrochloric acid 20...

Embodiment 3

[0037] 1) Preparation of amino-modified polyether polysiloxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 100 g of hydrogen-containing silicone oil, 4 g of allyl glycidyl ether, and 225 g of allyl polysiloxane in sequence. Oxyethylene polyoxypropylene ether, stirred with N2 for 10 minutes, heated up to 90°C, added dropwise a platinum catalyst to react for 4 hours to obtain a polyether / epoxy silicone oil intermediate. Then drop into ethylenediamine at a ratio of 1.05: 1.00 to the epoxy group molar ratio of amine and polyether / epoxy silicone oil intermediate to continue the reaction for 4h. The mixed solvent with a weight ratio of 9:1 was washed to remove impurities to obtain a viscous liquid.

[0038] 2) Preparation of polypropylmethylsilsesquioxane: In a reaction vessel equipped with a stirrer, a reflux condenser, and a thermometer, add 140ml of methyltriethoxysilane, 60ml of propyltriethoxysilane, 0.0 1mol / L hydrochloric acid 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com