Formation process of lithium ion battery with lithium nickel cobalt manganese oxide

A technology for lithium ion batteries and lithium nickel cobalt manganese oxide, which is applied in the field of nickel cobalt lithium manganate lithium ion battery formation technology, can solve the problems of increased labor costs, influence on the appearance of batteries, and long formation methods, and achieves dense and uniform improvement. properties, avoid polarization and bulging, improve battery electrical performance and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

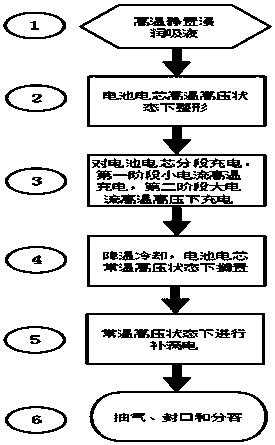

[0018] In this embodiment, a nickel-cobalt-manganese lithium-ion battery formation process, the specific steps are as follows:

[0019] Step 1: Inject electrolyte into the battery and put it aside for 4 hours under high temperature vacuum, so that the pole piece and diaphragm are quickly and fully infiltrated;

[0020] Step 2: Put the battery after the high temperature put aside in the integrated forming equipment that integrates the sectional variable pressure control system, the temperature control system, the time control system, and the forming charge and discharge function. The temperature is 50℃ and the pressure is 0.7Mpa. Reshape the battery core for 1 hour under high pressure to ensure the battery core is flat and make the interface between the positive and negative plates react well;

[0021] Step 3: Charge in two stages. In the first stage, the battery is charged to 30% SOC with a low current of 0.2C at a high temperature, and in the second stage, the battery is charged to ...

Embodiment 2

[0027] In this embodiment, a nickel-cobalt-manganese lithium-ion battery formation process, the specific steps are as follows:

[0028] Step 1: Inject electrolyte into the battery and put it aside for 5 hours under high temperature vacuum to make the pole piece and diaphragm quickly and fully wetted;

[0029] Step 2: Put the battery that has been left at a high temperature into an integrated forming equipment that integrates sub-variable pressure control system, temperature control system, time control system, and forming charge and discharge function at a temperature of 55°C and a pressure of 0.8Mpa. Carry out cell core shaping for 1.5 hours under the state to ensure the cell core is flat and make the positive and negative plate interface react well;

[0030] Step 3: Charge in two stages. In the first stage, the battery is charged to 30% SOC with a low current of 0.25C at a high temperature, and in the second stage, the battery is charged to a high current of 0.75C and charged to 65...

Embodiment 3

[0035] In this embodiment, a nickel-cobalt-manganese lithium-ion battery formation process, the specific steps are as follows:

[0036] Step 1: Inject electrolyte into the battery and put it aside for 6 hours under high temperature vacuum to make the pole piece and diaphragm quickly and fully wetted;

[0037] Step 2: Put the battery that has been left at high temperature in an integrated forming equipment that integrates sub-variable pressure control system, temperature control system, time control system, and forming charge and discharge function at a temperature of 60°C and a pressure of 0.9Mpa. Reshape the battery core for 2 hours in the state to ensure that the battery core is flat and make the interface between the positive and negative plates react well;

[0038] Step 3: Charge in two stages. In the first stage, the battery is charged to 30% SOC with a low current of 0.3C at a high temperature, and in the second stage, the battery is charged to a high current of 1C and charged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com