Formation and aging combined method of soft package lithium ion battery and soft package lithium ion battery

A technology of ion battery and lithium ion, which is applied in the direction of secondary battery charging/discharging, secondary battery, electrochemical generator, etc., and can solve the problems affecting the cycle performance and long process of lithium ion battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

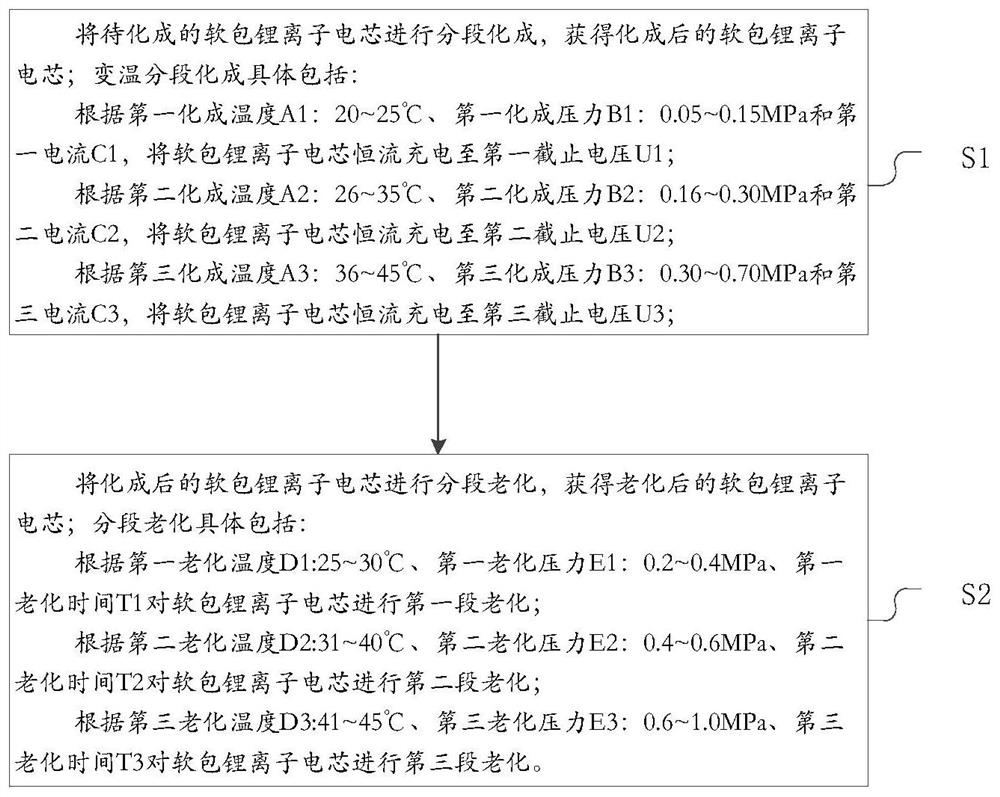

Method used

Image

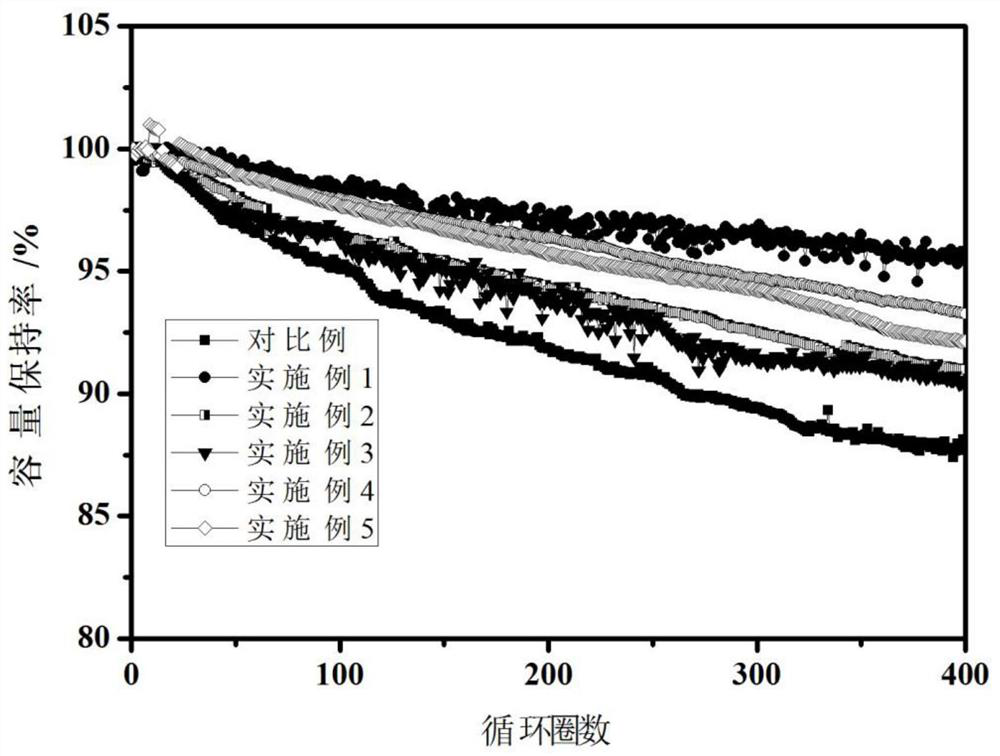

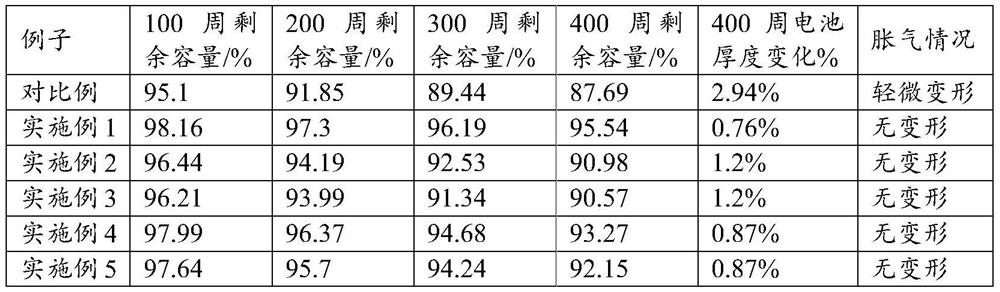

Examples

Embodiment 1

[0064] Place the battery in the formation-aging integrated device to perform formation according to the following three stages of formation:

[0065] (1) Set the fixture temperature to 20°C and the fixture pressure to 0.05MPa. After the temperature and pressure reach the set value, let it stand for 5 minutes, and then charge it to 3.45V with a constant current of 0.05C;

[0066] (2) Set the temperature of the fixture to 30°C, the pressure of the fixture to 0.2MPa, raise the temperature, increase the pressure, let the temperature and pressure reach the set value, let it stand for 5 minutes, and then charge it with a constant current of 0.1C to 3.8V;

[0067] (3) Set the temperature of the fixture to 40°C, the pressure of the fixture to 0.4MPa, raise the temperature, increase the pressure, let the temperature and pressure reach the set value and let it stand for 5 minutes, and then charge it to 3.95V with a constant current of 0.2C;

[0068] The aging steps are as follows:

[0...

Embodiment 2

[0074] Place the battery in the formation-aging integrated device to perform formation in the following three stages:

[0075] (1) Set the fixture temperature to 20°C and the fixture pressure to 0.1MPa. After the temperature and pressure reach the set value, let it stand for 5 minutes, and then charge it to 3.25V with a constant current of 0.05C;

[0076] (2) Set the temperature of the fixture to 30°C, the pressure of the fixture to 0.3MPa, raise the temperature, increase the pressure, let the temperature and pressure reach the set value and let it stand for 5 minutes, and then charge it to 3.65V with a constant current of 0.1C;

[0077] (3) Set the temperature of the fixture to 40°C, the pressure of the fixture to 0.7MPa, raise the temperature and increase the pressure, let the temperature and pressure reach the set value and let it stand for 5 minutes, then charge it with a constant current of 0.2C to 3.95V;

[0078] The aging steps are as follows:

[0079] (1) Set the fixt...

Embodiment 3

[0084] Place the battery in the formation-aging integrated device to perform formation in the following three stages:

[0085] (1) Set the fixture temperature to 25°C and the fixture pressure to 0.05MPa. After the temperature and pressure reach the set value, let it stand for 5 minutes, and then charge it to 3.45V with a constant current of 0.05C;

[0086] (2) Set the fixture temperature to 35°C, the fixture pressure to 0.2MPa, raise the temperature and increase the pressure, let the temperature and pressure reach the set value and let it stand for 5 minutes, then charge it with a constant current of 0.1C to 3.8V;

[0087] (3) Set the temperature of the fixture to 45°C, the pressure of the fixture to 0.4MPa, raise the temperature and increase the pressure, let the temperature and pressure reach the set value and let it stand for 5 minutes, then charge it to 4.1V with a constant current of 0.2C;

[0088] The aging steps are as follows:

[0089] (1) Set the fixture temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com