Method and tool for mounting assembly type ceramic tiles

An installation method and technology of installation tools, which can be applied to buildings, building structures, etc., can solve the problems of limited construction quality and efficiency, individual bricklayer technical level, noise pollution, and difficulty in ensuring construction quality and efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

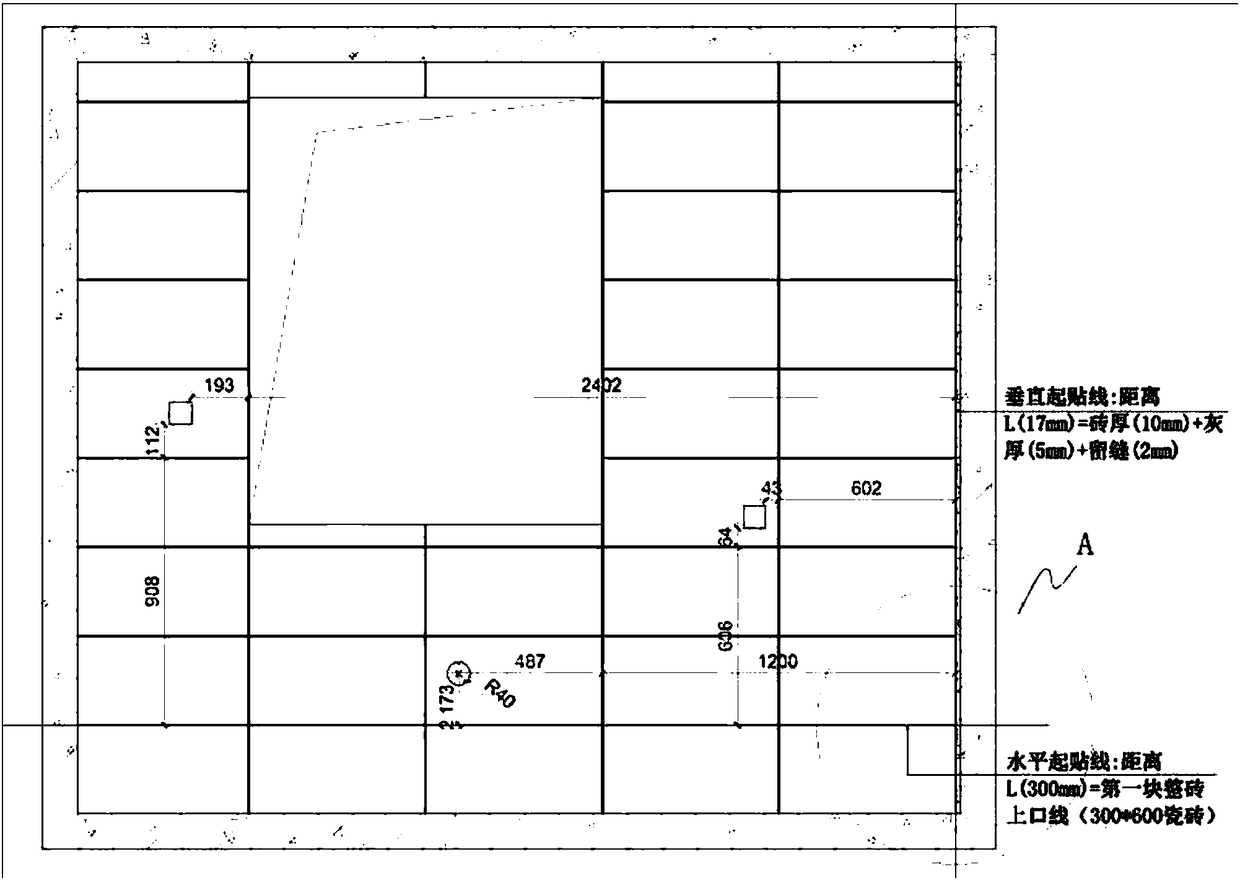

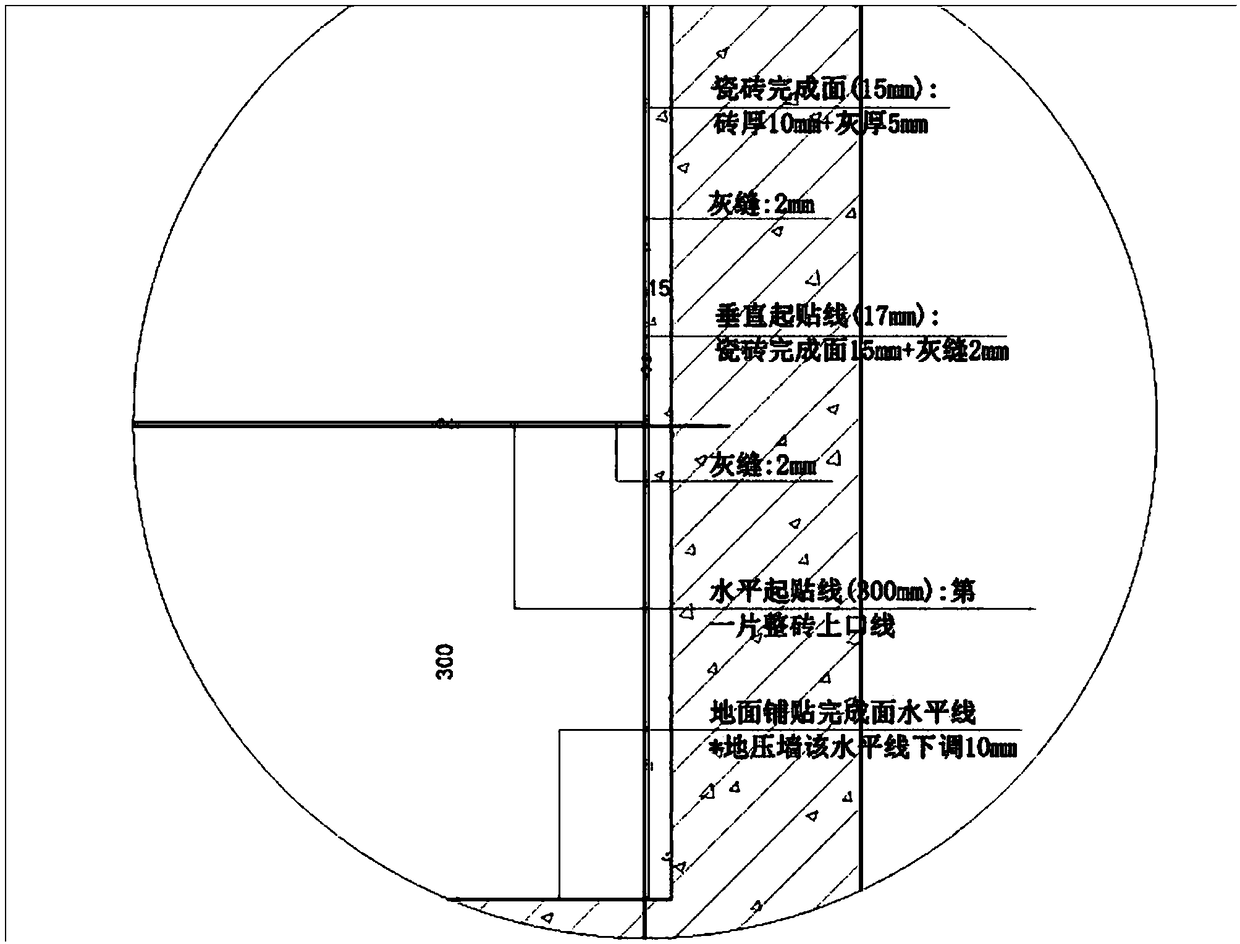

[0033] ginseng figure 1 and figure 2 As shown, taking the laying of kitchen wall and floor tiles as an example, the installation methods of prefabricated tiles include:

[0034] 1) Surveyors survey and measure.

[0035] Before paving, the site should be inspected first, and the indicators such as flatness, verticality, and squareness of the yin and yang angles of the base layer should be inspected.

[0036] 2) Leveling the bricklaying infrastructure (leveling the wall and ground).

[0037] For the leveling treatment of the walls and ground bases that do not meet the standards, this work is completed by the master leveling bricklayer. After the leveling is completed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com