Novel railway ballast cleaning method

A technology for track beds and railways, applied in track cleaning, cleaning methods, construction, etc., can solve problems such as endangering the safety of train operation, vehicle failure, damage to vehicle sensor electronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

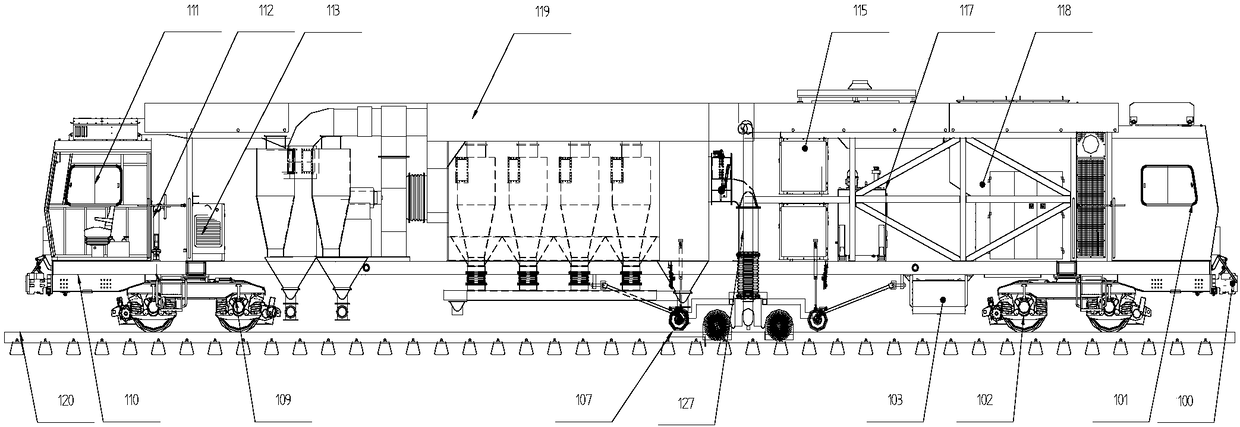

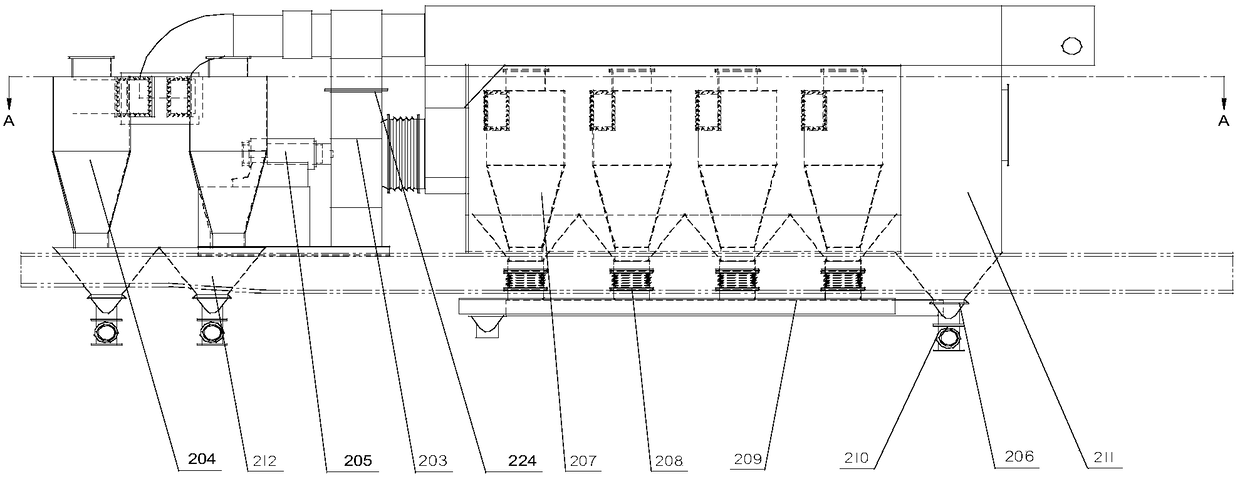

[0040] Embodiment 1.1: a kind of novel railway track bed decontamination method, it adopts a kind of novel railway track bed decontamination vehicle, such as figure 1 As shown, a front driver's cab 111 and a rear driver's cab 101 are respectively installed at both ends of the vehicle frame 110; a secondary dust removal and storage and transportation device 201 is installed behind the front driver's cab 111, and a dust suction fan 203 is connected to the rear of the secondary dust removal and storage and transportation device 201 , the dust suction blower 203 is connected behind the first-level dust removal and storage and transportation device 202, the hydraulic system 117 is installed behind the first-level dust removal and storage and transportation device 202, the power room 118 is installed on the front side of the rear driver's cab 101, and the engine is installed Inside the power room 118, power is provided for the whole vehicle. The bottom of the vehicle frame 110 is als...

Embodiment 12

[0047] Embodiment 1.2: A new type of method for cleaning railway track beds, the same as Embodiment 1.1, the difference is that: the front roller brush motor and the rear roller brush motor are turned on at the same time, and the dust suction fan, roller brush and screw conveyor are all turned on to The maximum speed, the operating speed of the vehicle is controlled below 5km / h. Adjust the air volume regulator to match the exhaust air volume and reverse air volume, so that the dust content of the exhaust air meets the discharge standard requirements, and ensure that 95% of the dirt on the surface of the track bed is collected after operation. This embodiment is applied to working conditions with more dirt, such as absorbing thicker sand or compacted coal dust.

Embodiment 13

[0048] Embodiment 1.3: A new type of method for cleaning railway track beds, the same as Embodiment 1.1, the difference is that only the front or rear brush motor is turned on according to the working direction, the speed of the roller brush motor uses the lowest set speed, and the dust is collected The fan is adjusted to a medium speed, and a reasonable working speed is matched according to the working situation. This embodiment is applied to working conditions with less dirt or less specific gravity of dirt particles, such as absorbing abrasive debris after rail grinding.

[0049] A new type of railway track bed cleaning vehicle described in the above embodiment adopts a new cleaning method combining brush sweeping and blowing and suction, which can remove the deposited dirt above the track bed plate, greatly improving the suction efficiency; the dust removal method of two-stage dust removal is adopted , improve the dust removal efficiency, not only can handle different dirt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com