Biological fermentation product for preventing and treating colitis and preparation method thereof

A technology of biological fermentation and colitis, applied in the field of bioengineering, can solve problems such as short research time, and achieve the effect of high viable bacteria, increased polysaccharide content, and growth promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

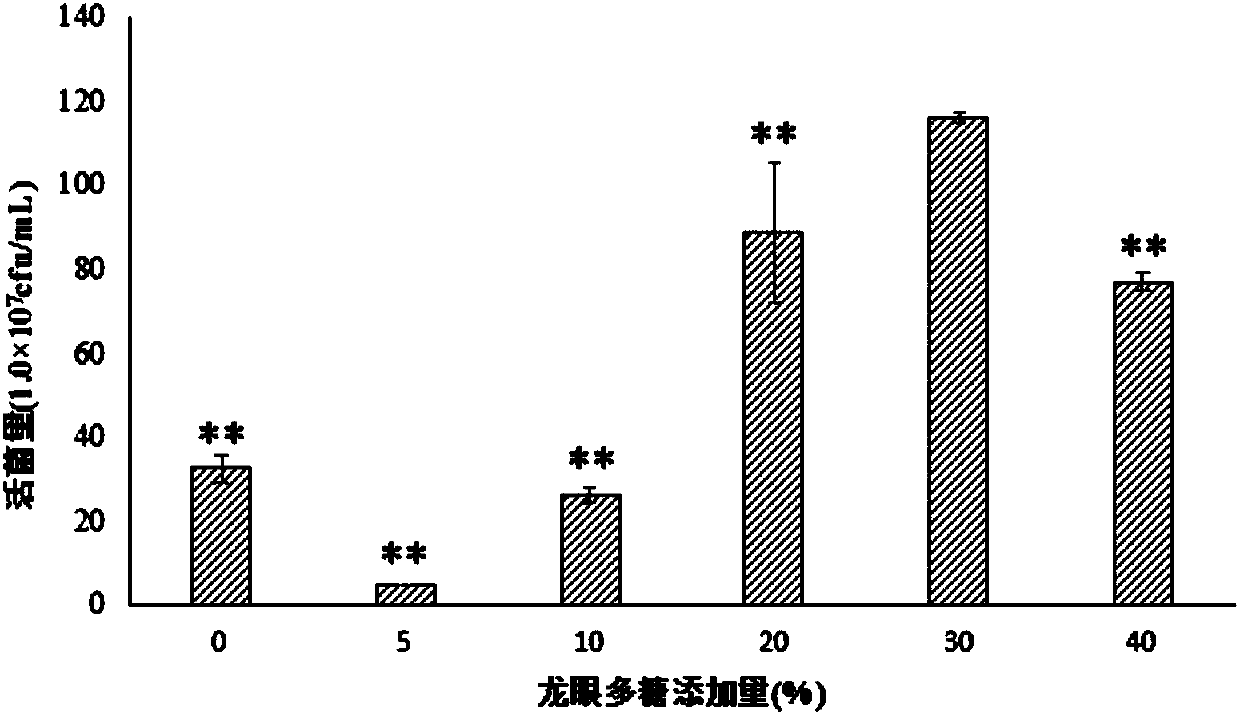

[0052] The fermentation process of embodiment 1 clostridium butyricum fermented longan

[0053] (1) Extraction method of longan extract

[0054] Take dried longan, mash and homogenate, mix water and longan pulp according to the liquid-to-solid ratio of 15ml:1g, and homogenize to obtain longan pulp slurry. Under the condition that the hydrolysis time was 187.0min, the enzyme hydrolysis extraction experiment was carried out on a shaker with a rotation speed of 120r / min. After the extraction, the enzyme was inactivated in a water bath at 80°C for 10 minutes. Filter through eight layers of gauze, discard the residue, and obtain the supernatant. The supernatant was concentrated under reduced pressure to 40% of the original volume to obtain the longan extract.

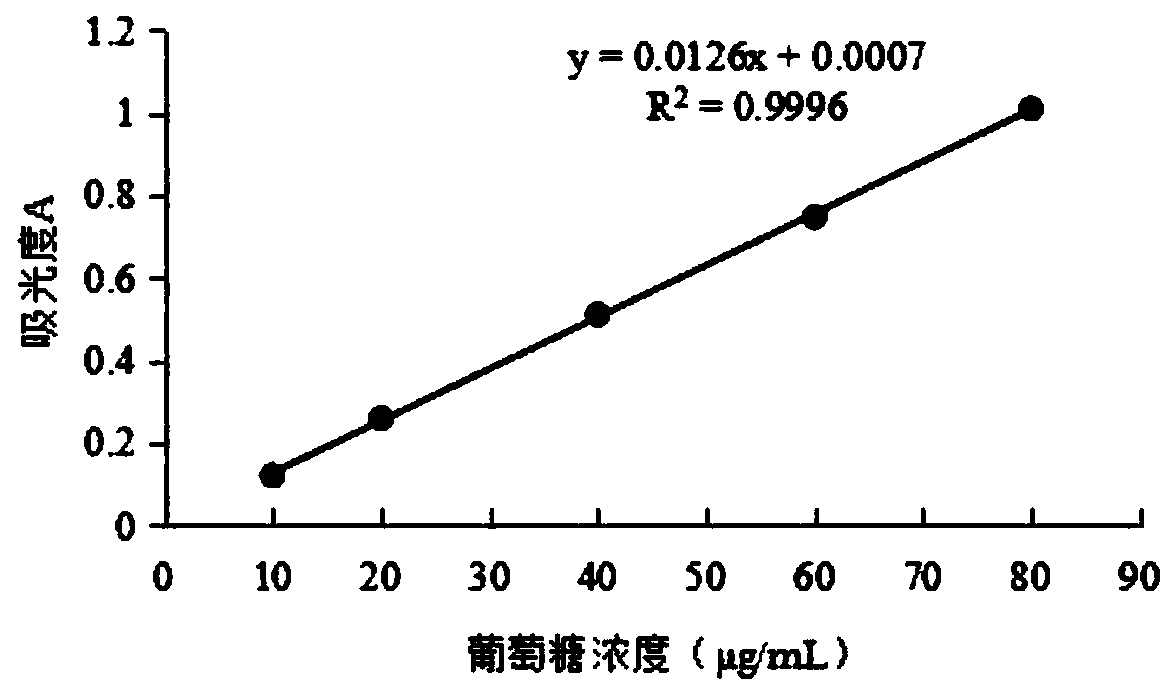

[0055] (2) Standard curve creation

[0056]Accurately weigh 100mg of dried glucose, dissolve it with deionized water and set the volume in a 100mL volumetric flask to obtain a 1mg / mL glucose standard solution. Accuratel...

Embodiment 2

[0069] The fermentation process of embodiment 2 clostridium butyricum fermentation longan

[0070] (1) Extraction method of longan extract

[0071] Take dried longan, mash and homogenate, mix water and longan pulp according to the liquid-to-material ratio of 20ml:1g, and homogenize to obtain longan pulp slurry, the amount of cellulase added is 2% w / v, the enzymolysis temperature is 60.0°C, and the enzyme Under the condition that the hydrolysis time was 210min, the enzyme hydrolysis extraction experiment was carried out on a shaker with a rotational speed of 120r / min. After the extraction, the enzyme was inactivated in a water bath at 80°C for 10 minutes, filtered through eight layers of gauze, and the residue was discarded to obtain the supernatant. The supernatant was concentrated under reduced pressure to 30% of the original volume to obtain a longan extract.

[0072] (2) Standard curve creation

[0073] Accurately weigh 100mg of dried glucose, dissolve it with deionized ...

Embodiment 3

[0085] The fermentation process of embodiment 3 clostridium butyricum fermented longan

[0086] (1) Extraction method of longan extract

[0087] Take dried longan, mash and homogenate, mix water and longan pulp according to the liquid-to-material ratio of 16ml:1g, and homogenize to obtain longan pulp slurry, the amount of cellulase added is 1.5% w / v, the enzymolysis temperature is 45.0°C, and the enzyme Under the condition of the hydrolysis time of 180min, the enzymolysis extraction experiment was carried out on a shaker with a rotation speed of 120r / min. After the extraction, the enzyme was inactivated in a water bath at 80°C for 10 minutes, filtered through eight layers of gauze, and the residue was discarded to obtain the supernatant. The supernatant was concentrated under reduced pressure to 30% of the original volume to obtain a longan extract.

[0088] (2) Standard curve creation

[0089] Accurately weigh 100mg of dried glucose, dissolve it with deionized water and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com