Gum dipping device for capsule production line

A production line and glue dipping technology, which is applied in capsule delivery, drug delivery, and pharmaceutical formulations, etc., can solve the problems of varying capsule disintegration time, complex structure of the glue dipping device, and poor overall stability, achieving high glue dipping efficiency, Time and effort saving, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

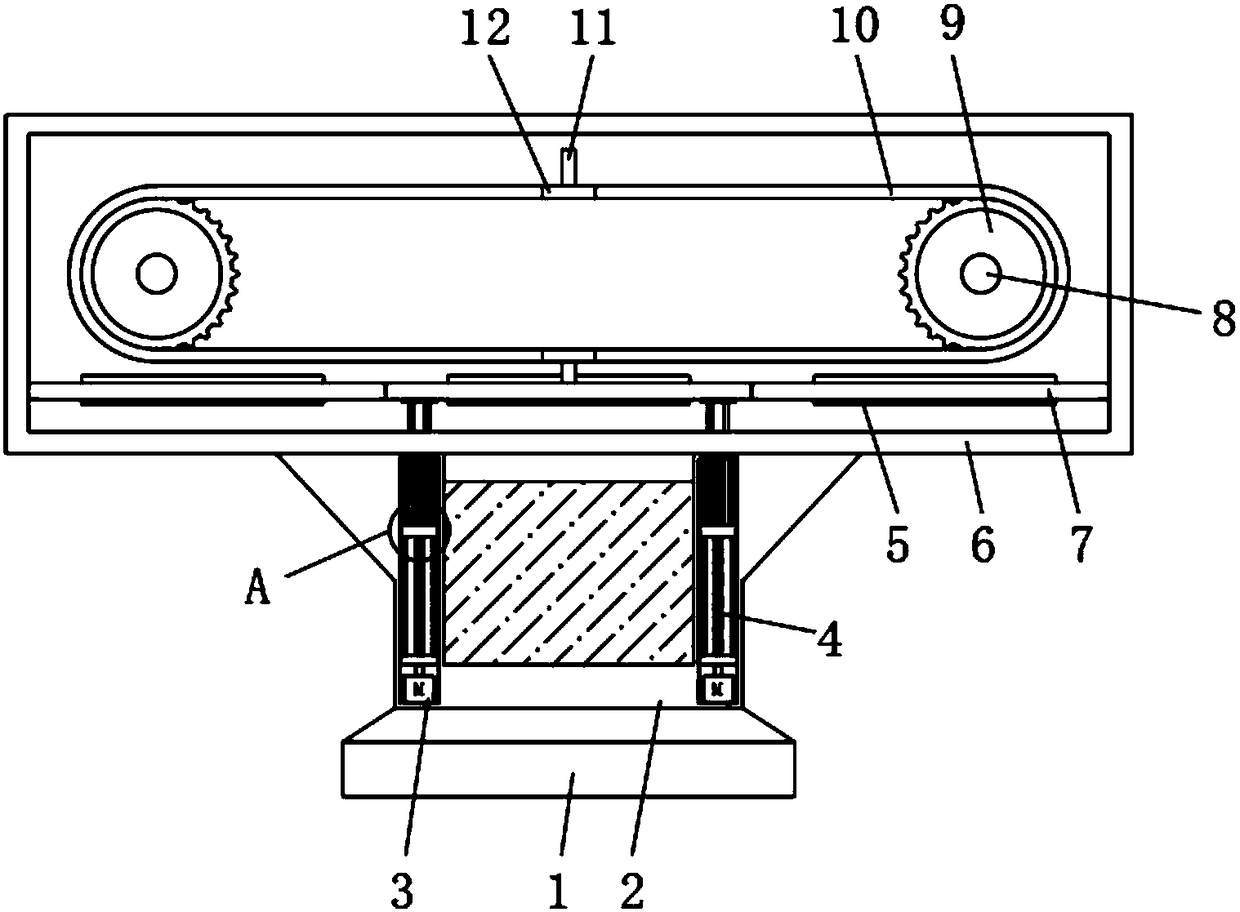

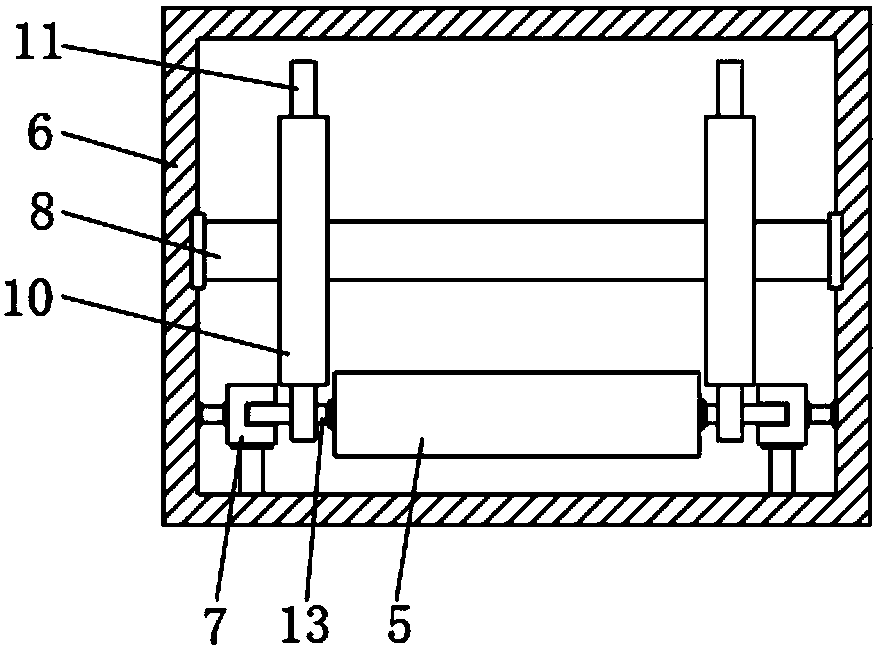

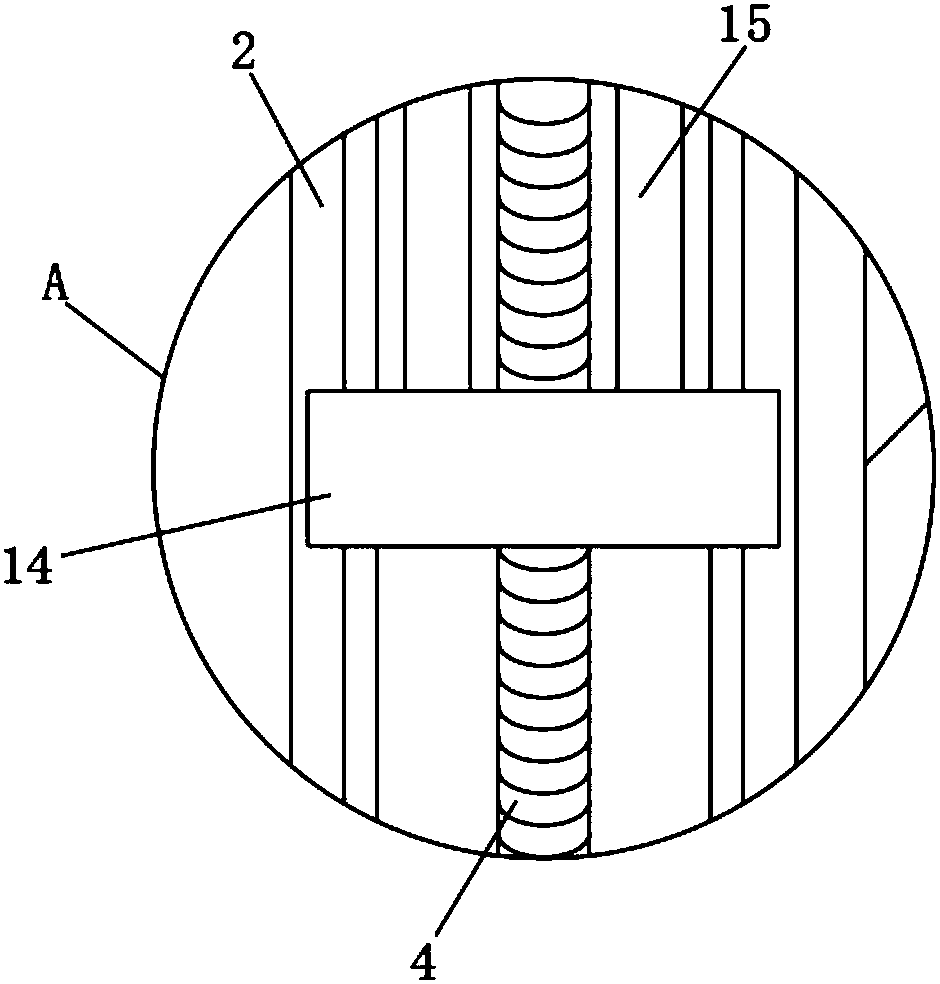

[0026] Embodiment 1: with reference to Figure 1-3 , the dipping device of the automatic capsule production line, including a base 1, the upper end of the base 1 is provided with a storage barrel 2 for placing liquid, and the upper end of the storage barrel 2 is fixedly connected with a protective cover 6, and the protective cover 6 is symmetrically rotated and connected with Two rotating shafts 8, each rotating shaft 8 is equipped with a gear 9 symmetrically, and the gear 9 on the same side of the two rotating shafts 8 is provided with a chain 10, and each chain 10 is provided with two moving blocks 12, Each moving block 12 has the same structure as the chain 10; the side of each moving block 12 away from the gear 9 is provided with a driving lever 11, which is used to make the placement frame 5 move on the sliding rod 7, and the driving rod 11 is located on the sliding rod 7 Between the shelf 5 and the side wall of the protective cover 6, two sliding rods 7 are symmetrically...

Embodiment 2

[0032] Embodiment 2: The performances of Embodiment 1 and commercially available common capsule shells were tested, and the obtained data are shown in the table below.

[0033] 1. Determination of transparency: the sample’s internal light reflection factor and the difference between the light reflection factor and the percentage of the internal light reflection factor are measured with a whiteness meter. The method refers to QB / T1913-2004.

[0034] 2. Measurement of softness: measured with a Shore hardness tester.

[0035] group

[0036] It can be seen from the above results that the capsule shell of the present invention can improve the weather resistance of the capsule shell, and when the drug effect is guaranteed at low temperature, it does not affect the life of the capsule shell and widens the scope of use of the capsule shell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com