Functional lithium-sulfur battery diaphragm and preparation method thereof

A lithium-sulfur battery, functional technology, applied in the field of lithium-sulfur battery diaphragm and its preparation, can solve the problems of lithium-sulfur battery actual capacity reduction, hindering electrons, ion transport electrochemical reaction, attenuation, etc., to achieve high-efficiency chemical adsorption and physical Barrier, suppression of shuttle effect, effect of high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

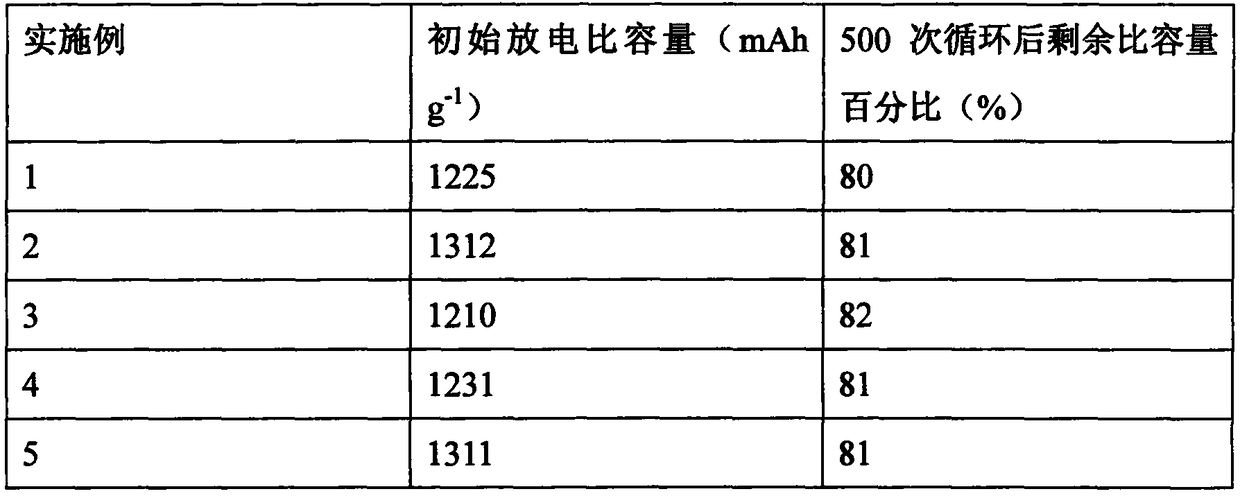

Examples

Embodiment 1

[0029] A functional lithium-sulfur battery separator is a nanofiber membrane formed by electrospinning a fluorine-containing polyimide resin material polymerized from a fluorine-containing diamine monomer and a dianhydride monomer.

[0030] The preparation method of the above-mentioned functional lithium-sulfur battery diaphragm is as follows:

[0031] Step 1: Prepare highly soluble fluorine-containing polyimide resin material: Add 0.96g of fluorine-containing diamine monomer 6FDA and 0.69g of dianhydride mono ODPA, 14.5mL reaction solvent NMP and 0.5ml catalyst isoquinoline, stirred at room temperature under the protection of nitrogen until the monomer was completely dissolved, using the stepwise heating method, slowly raised the temperature to 80°C for 2h, 120°C for 4h, 200°C Maintained for 10h to obtain a polymer solution.

[0032] The second step: slowly add the obtained polymer solution into the syringe, the diameter of the needle (ie spinneret) closely connected with th...

Embodiment 2

[0035] A functional lithium-sulfur battery separator is a nanofiber membrane formed by electrospinning a fluorine-containing polyimide resin material polymerized from a fluorine-containing diamine monomer and a dianhydride monomer.

[0036] The preparation method of the above-mentioned functional lithium-sulfur battery diaphragm is as follows:

[0037] Step 1: Prepare highly soluble fluorine-containing polyimide resin material: Add 0.85 g of fluorine-containing diamine monomer 2,2-bis[4 -(4-Aminophenylthio)phenyl]hexafluoropropane and 0.71g dianhydride monomer PMDA, 15.5mL reaction solvent NMP and 0.5ml catalyst triethylamine, stir at room temperature under nitrogen protection until the monomer is completely dissolved , using a stepwise heating method, the temperature was gradually raised to 80°C for 2h, 120°C for 4h, and 200°C for 10h to obtain a polymer solution.

[0038] Step 2: Slowly add the obtained polymer solution into the syringe, the diameter of the needle (ie spinn...

Embodiment 3

[0041] A functional lithium-sulfur battery separator is a nanofiber membrane formed by electrospinning a fluorine-containing polyimide resin material polymerized from a fluorine-containing diamine monomer and a dianhydride monomer.

[0042] The preparation method of the above-mentioned functional lithium-sulfur battery diaphragm is as follows:

[0043] Step 1: Prepare highly soluble fluorine-containing polyimide resin material: Add 0.73g of fluorine-containing diamine monomer 2,2-dihydroxybenzene into a 50mL three-necked flask equipped with mechanical stirring, reflux condenser and nitrogen inlet and outlet Base hexafluoropropane and 0.52g dianhydride monomer BPDA, 17mL reaction solvent NMP and appropriate amount of catalyst isoquinoline 0.2ml, stir at room temperature under nitrogen protection until the monomer is completely dissolved, adopt stepwise heating method, slowly raise the temperature to 80°C and maintain 2h, maintained at 120°C for 4h, and maintained at 200°C for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com