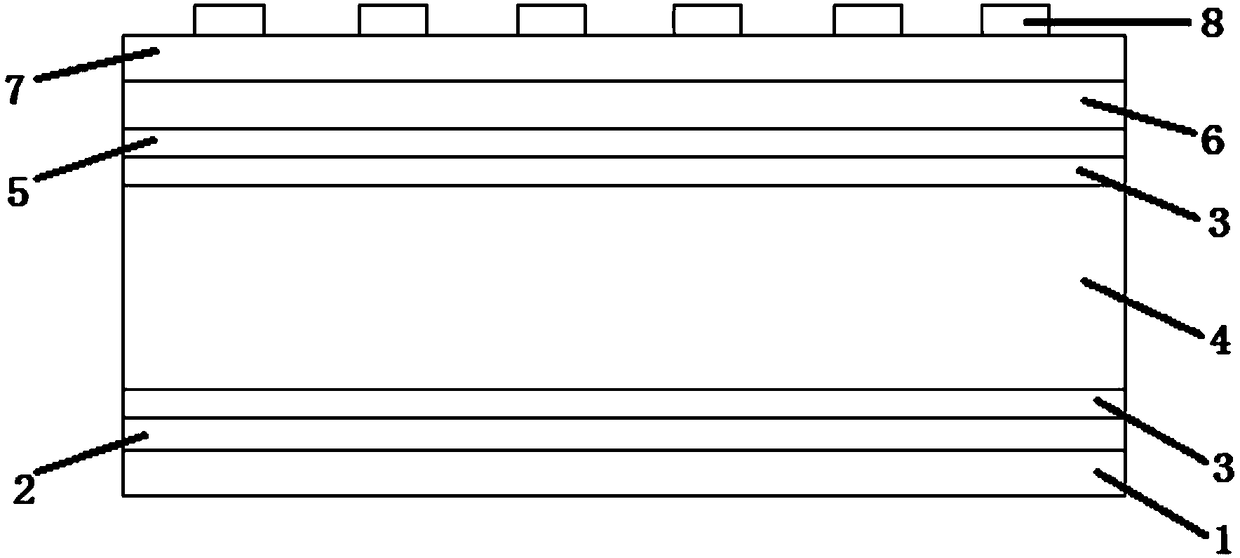

Silicon heterojunction solar cell and preparation method thereof

A solar cell and silicon heterojunction technology, applied in the field of solar cells, can solve the problems of difficult large-scale application, high cost, and low photoelectric conversion efficiency, and achieve the goals of easy industrial production, improved contact barrier, and improved photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A method for preparing a silicon heterojunction solar cell proposed in a specific embodiment of the present invention comprises the following steps:

[0025] (1) Carry out texturing treatment to n-type silicon chip, then soak in acidic solution to remove the natural silicon oxide layer on the surface of n-type silicon chip;

[0026] (2) Passivate the n-type silicon chip: spin-coat a mixed solution containing yttrium n-propoxide and hafnium n-propoxide on the upper surface of the n-type silicon chip, and dry it, then apply the n-type silicon chip on the n-type silicon chip The lower surface of the n-type silicon wafer is spin-coated with the above-mentioned mixed solution containing yttrium n-propoxide and hafnium n-propoxide, and then annealed for the first time to form a passivation film on the upper and lower surfaces of the n-type silicon wafer;

[0027] (3) Preparation of strontium chloride interface modification film: the upper surface of the n-type silicon wafer o...

Embodiment 1

[0036] A method for preparing a silicon heterojunction solar cell, comprising the following steps: (1) carrying out texturing treatment to an n-type silicon wafer, and then soaking in an acidic solution to remove the natural silicon oxide layer on the surface of the n-type silicon wafer; (2) ) Passivating the n-type silicon chip: spin-coating a mixed solution containing yttrium n-propoxide and hafnium n-propoxide on the upper surface of the n-type silicon chip, and drying it, then coating the n-type silicon chip The lower surface of the chip is spin-coated with the above-mentioned mixed solution containing yttrium n-propoxide and hafnium n-propoxide, and then annealed for the first time to form a passivation film on the upper and lower surfaces of the n-type silicon chip; (3) strontium chloride Preparation of interface modification film: spin-coat an aqueous solution containing strontium chloride on the upper surface of the n-type silicon wafer obtained in step (2), wherein the...

Embodiment 2

[0040] A method for preparing a silicon heterojunction solar cell, comprising the following steps: (1) carrying out texturing treatment to an n-type silicon wafer, and then soaking in an acidic solution to remove the natural silicon oxide layer on the surface of the n-type silicon wafer; (2) ) Passivating the n-type silicon chip: spin-coating a mixed solution containing yttrium n-propoxide and hafnium n-propoxide on the upper surface of the n-type silicon chip, and drying it, then coating the n-type silicon chip The lower surface of the chip is spin-coated with the above-mentioned mixed solution containing yttrium n-propoxide and hafnium n-propoxide, and then annealed for the first time to form a passivation film on the upper and lower surfaces of the n-type silicon chip; (3) strontium chloride Preparation of interface modification film: spin-coat an aqueous solution containing strontium chloride on the upper surface of the n-type silicon wafer obtained in step (2), wherein the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com