Low inclusion pipeline steel production method

A production method and low-inclusion technology, which is applied in the production field of low-inclusion pipeline steel, can solve problems such as excessive B-type inclusions, adverse effects on product quality and enterprise benefits, and failure of flaw detection, so as to reduce oxidation or oxygen content , Saving process costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

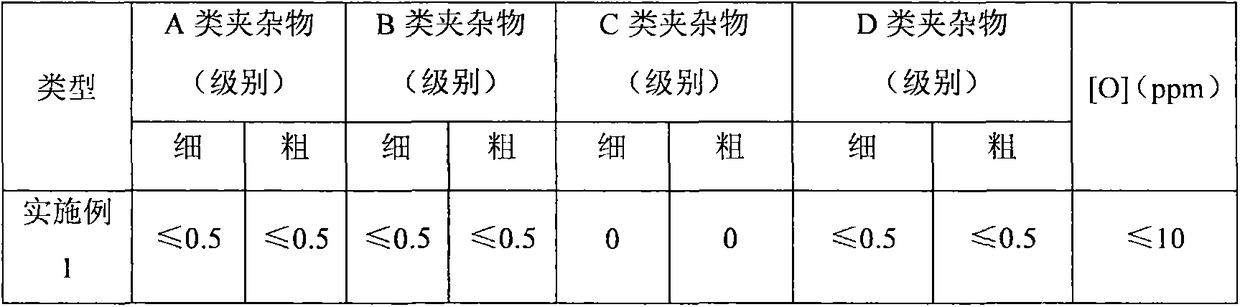

Examples

Embodiment 1

[0046] The production method of low-inclusion pipeline steel is characterized in that the composition of pipeline steel is C 0.062%, Si 0.25%, Mn 1.75%, P≤0.015%, S≤0.005%, Nb 0.07%, Ti 0.010%, Al≤0.050 %, Cr 0.5%, Mo0.55%, Ni 0.2%, Cu 0.15%, W 0.005%, Zr 0.0001%, Ta 0.0001%, rare earth (Sc+Y) 0.0001%, Sc:Y mass ratio is 4:1, B 0.0001%, N 0.001%, and the balance is Fe and unavoidable impurity elements.

[0047] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the core steps are as follows:

[0048](1) KR molten iron pretreatment desulfurization: oxygen blowing time is 20-22min, oxygen supply intensity is 10000-13000m3 / h, S content of molten iron before treatment is ≤0.03%, desulfurizer addition is 14-15kg / t, iron after treatment The sulfur content in the water is ≤0.001%; the mass of lime powder in the desulfurizer accounts for 90-95%, and the mag...

Embodiment 2

[0056] The production method of low-inclusion pipeline steel is characterized in that: the composition of pipeline steel is C 0.063%, Si 0.27%, Mn 1.76%, P≤0.015%, S≤0.005%, Nb 0.08%, Ti 0.011%, Al≤0.050 %, Cr 0.6%, Mo0.58%, Ni 0.22%, Cu 0.18%, W 0.007%, Zr 0.0002%, Ta 0.001%, rare earth (Sc+Y) 0.0002%, Sc:Y mass ratio is 5:1, B 0.0002%, N 0.003%, and the balance is Fe and unavoidable impurity elements.

[0057] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the core steps are as follows:

[0058] (1) KR molten iron pretreatment desulfurization: oxygen blowing time is 20-22min, oxygen supply intensity is 10000-13000m3 / h, S content of molten iron before treatment is ≤0.03%, desulfurizer addition is 14-15kg / t, iron after treatment The sulfur content in the water is ≤0.001%; the mass of lime powder in the desulfurizer accounts for 90-95%, and the m...

Embodiment 3

[0066] The production method of low-inclusion pipeline steel is characterized in that: the composition of pipeline steel is C 0.065%, Si 0.3%, Mn 1.78%, P≤0.015%, S≤0.005%, Nb 0.095%, Ti 0.012%, Al≤ 0.050%, Cr 0.65%, Mo0.6%, Ni 0.25%, Cu 0.19%, W 0.008%, Zr 0.0004%, Ta 0.005%, rare earth (Sc+Y) 0.0005%, Sc:Y mass ratio is 5:1 , B 0.0005%, N 0.005%, and the balance is Fe and unavoidable impurity elements.

[0067] The process route includes: ratio preparation → hot metal pretreatment desulfurization → converter smelting → LF refining → RH refining → continuous casting → rolling → coiling; the core steps are as follows:

[0068] (1) KR molten iron pretreatment desulfurization: oxygen blowing time is 20-22min, oxygen supply intensity is 10000-13000m3 / h, S content of molten iron before treatment is ≤0.03%, desulfurizer addition is 14-15kg / t, iron after treatment The sulfur content in the water is ≤0.001%; the mass of lime powder in the desulfurizer accounts for 90-95%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com