Automatic control circulating type peanut oil aflatoxin degrading machine

A technology of aflatoxin and peanut oil is applied in the field of automatic control cycle type peanut oil aflatoxin degrading machine, which can solve the problems of large volume of multi-stage degrading machine, increase production cost, affect oil quality and the like, and achieve easy popularization and application. , Guarantee quality, improve the effect of sterilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

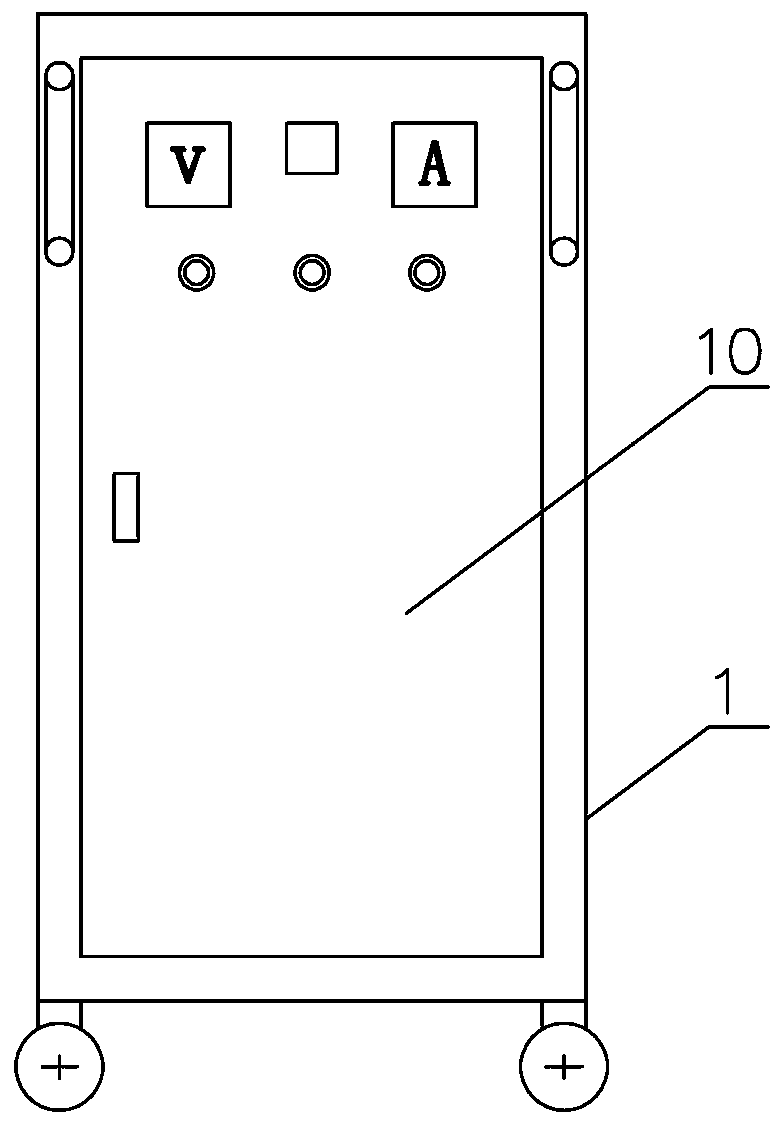

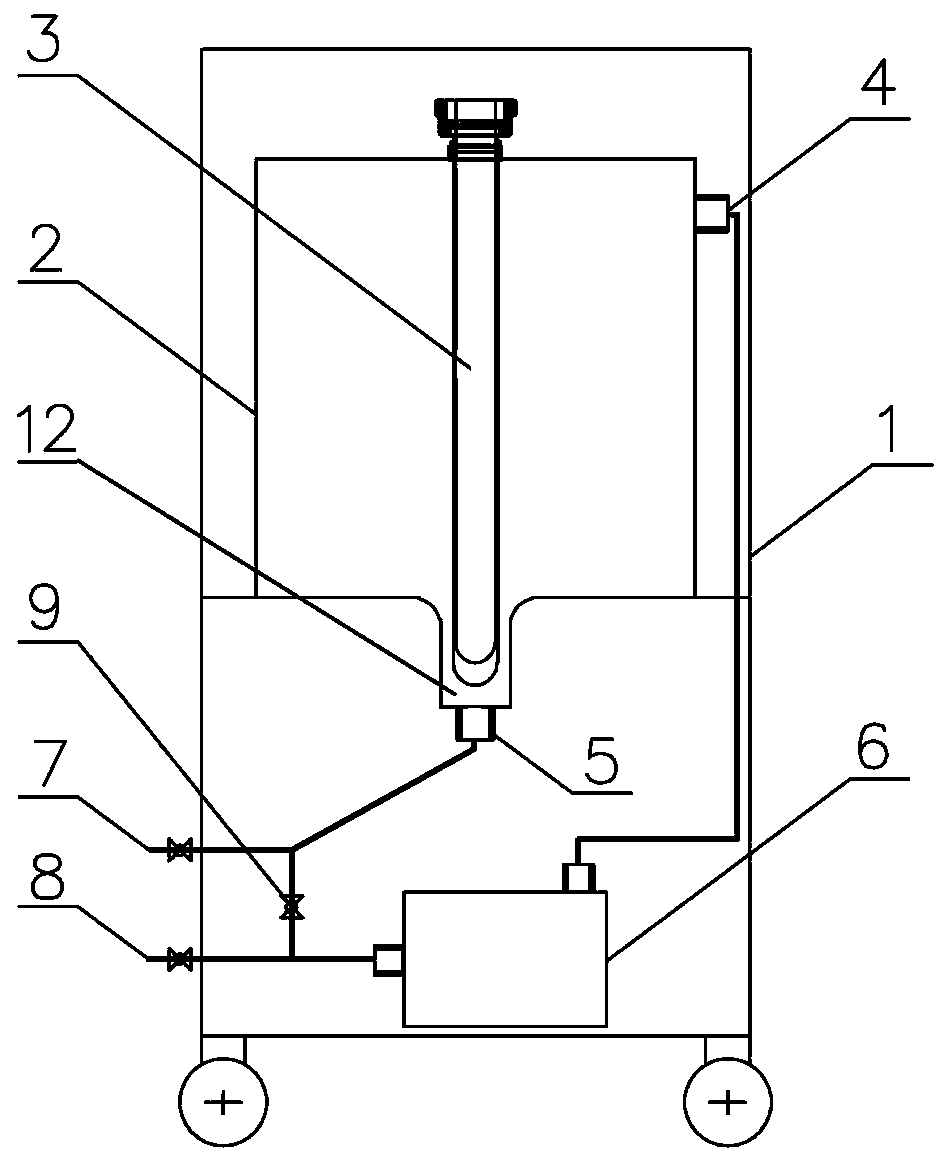

[0027] figure 1 It is a schematic diagram of the front panel and control cabinet of the automatic control circulation peanut oil aflatoxin degradation machine, figure 2 It is a schematic diagram of the internal structure. The oil storage tank is provided with an inlet and an outlet. The oil storage tank is equipped with an ultraviolet lamp. The barrel outlet is respectively connected to the oil outlet of the chassis and the regulating valve, and the other end of the regulating valve is connected to the oil supply pump; on the front panel of the chassis, there is a control cabinet, which is electrically connected to the oil supply pump and the ultraviolet lamp.

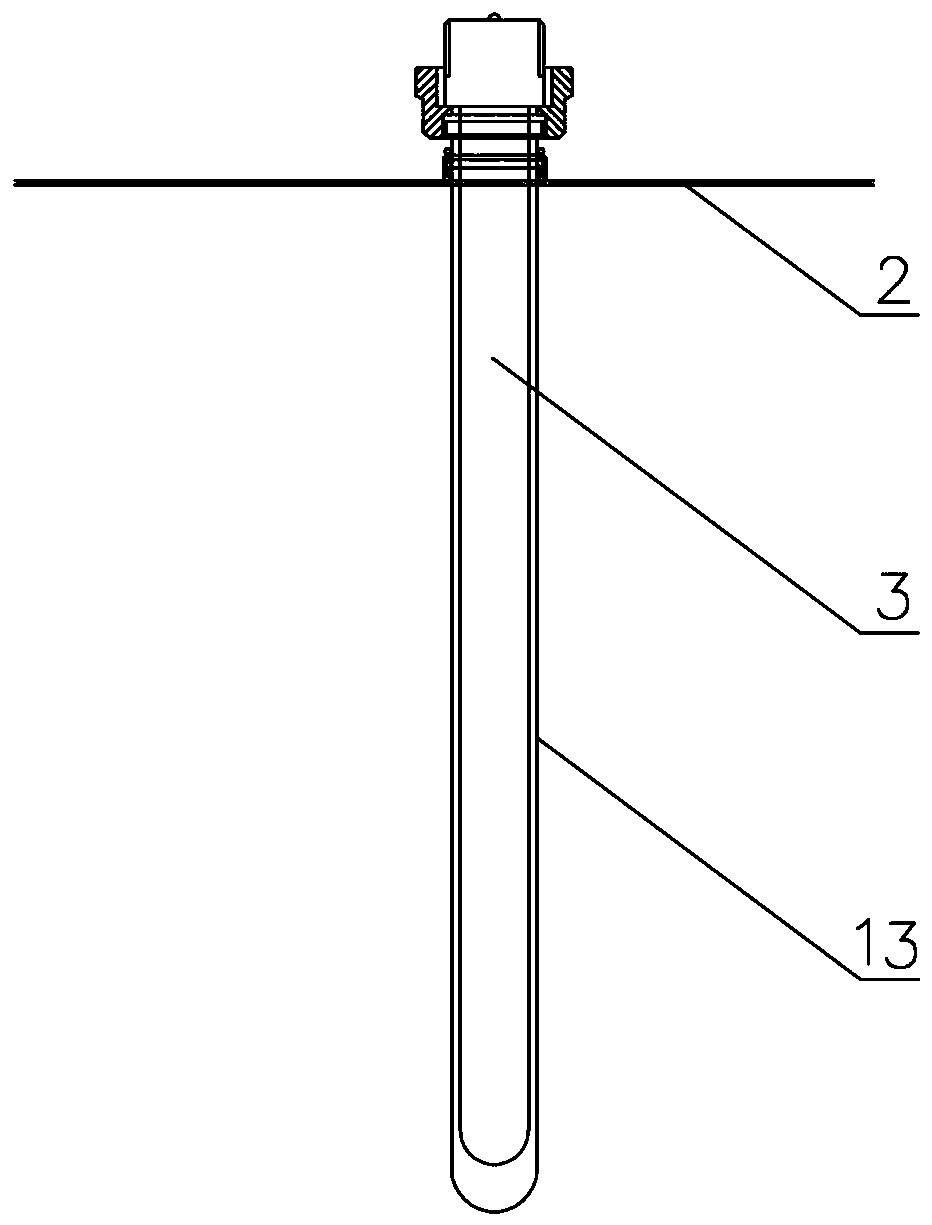

[0028] The oil storage barrel is cylindrical and made of food-grade polished stainless steel. The ultraviolet lamp is set at the axis of the cylindrical oil storage barrel, and the outlet of the oil storage barrel is set below the axis of the oil storage barrel. A double-layer quartz glass casing is placed on the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com