A Method for Reducing Internal Cracks in Temperature Sensitive Large Length-to-Diameter Ratio PBX Forming

A temperature-sensitive, large aspect ratio technology, applied in non-explosive/non-thermal agent components, explosives, non-explosive fillers/gelling agents/thickeners, etc., can solve penetrating cracks, grain heat, force Problems such as uneven distribution, weapon detonation performance, mechanical performance and safety performance, etc., achieve the effect of reducing cooling temperature and reducing thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

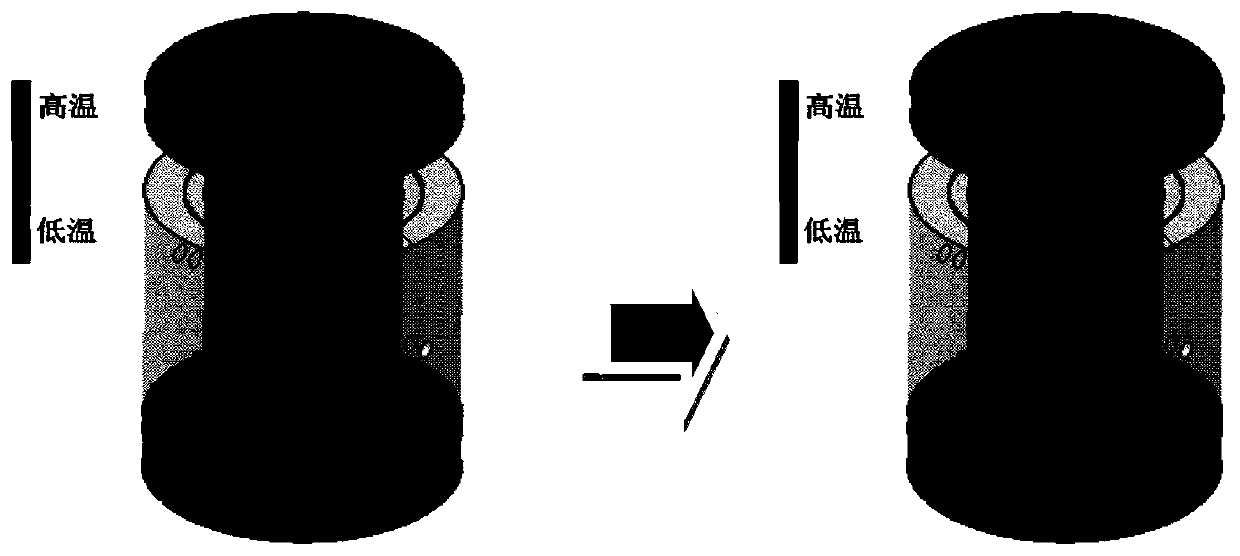

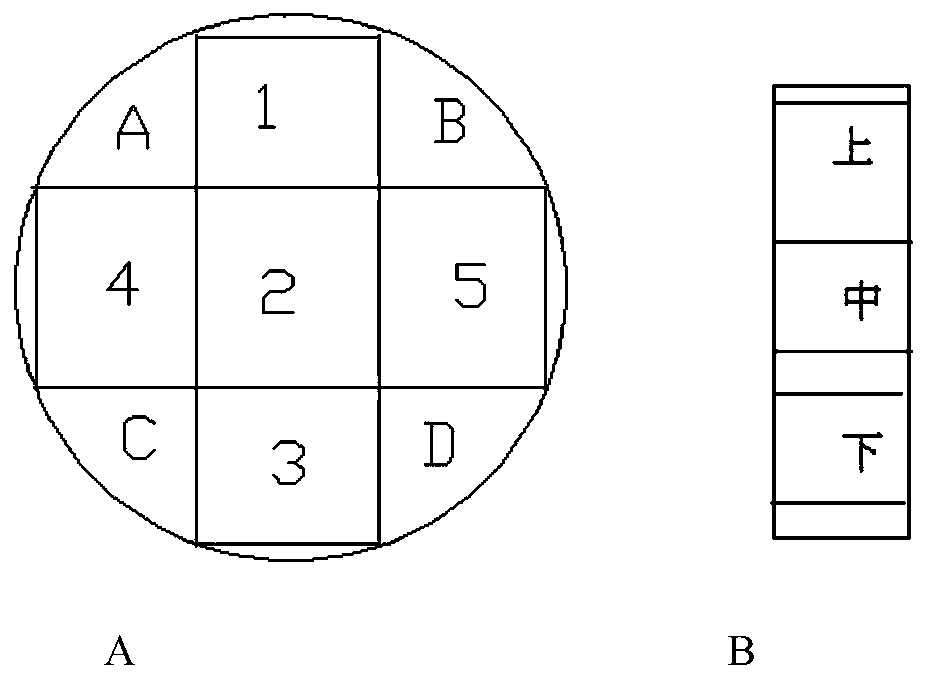

[0024] as attached figure 1 As shown, it is a schematic diagram of a conventional device for the compression molding process. The top is the upper punch, the middle is the mold sleeve, and the bottom is the base. figure 1 The left side shows the temperature characteristics of the existing conventional compression molding process. It can be seen that the temperature gradually increases from the base to the upper punch. figure 1 As shown on the right, the temperature of the base is higher than the temperature of the die sleeve, the temperature of the die sleeve is higher than the temperature of the upper punch, the temperature difference between the adjacent base temperature and the temperature of the die sleeve, the temperature of the die sleeve and the temperature of the upper punch, that is, the temperature gradient Greater than 5°C, not high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com