Ammonium-sulfate-coated urea nitrogen fertilizer, ammonium-sulfate-coated urea sustained-controlled release fertilizer and their preparation and application

A technology of coating urea and ammonium sulfate, which is applied in the direction of urea compound fertilizer, application, nitrogen fertilizer, etc., can solve the problems of poor controllability of fertilizer release rate, limit the application of food crops, and poor control of film thickness, so as to improve the utilization rate of nitrogen fertilizer , lower concentration, lower ammonia volatilization loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) 25 parts of ammonium sulfate are mixed with water to obtain a saturated solution of ammonium sulfate;

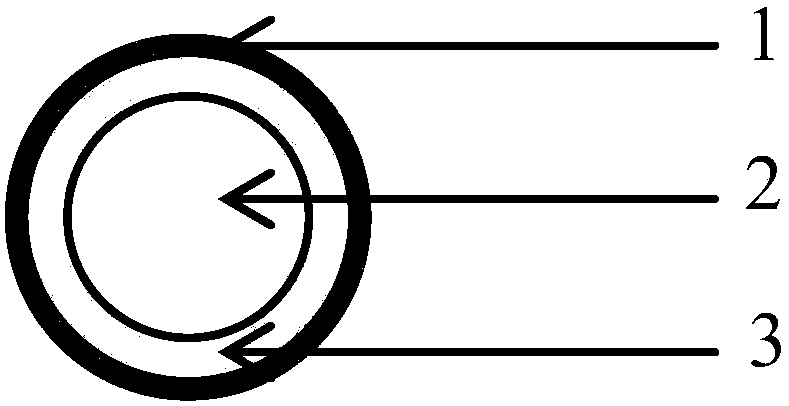

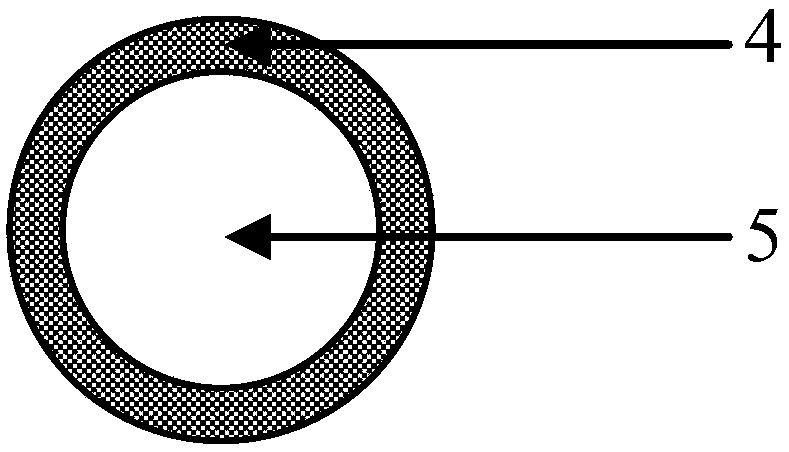

[0050] (2) Place 75 parts of urea granules in a stirring dryer at 60°C, and in a stirring state at 60 rpm, spray the saturated ammonium sulfate solution prepared in step (1) in the stirring dryer to make the aqueous solution of ammonium sulfate uniform Coated on the surface of urea granules (with a particle size of 3-4mm), the spraying speed of the ammonium sulfate aqueous solution should be such that the surface of the urea is wet but does not produce water accumulation; Sieve to obtain the ammonium sulfate-coated urea nitrogen fertilizer with urea as the inner core and the ammonium sulfate layer coated outside the inner core (the structure schematic diagram is shown in figure 1 ).

[0051] The ammonium sulfate coated urea nitrogen fertilizer that the present embodiment makes is suitable for sticky heavy soil; Its concrete application method is:

[0052] Winter...

Embodiment 2

[0057] (1) 20 parts of ammonium sulfate are mixed with water to obtain a saturated solution of ammonium sulfate;

[0058] (2) 80 parts of urea granules are placed in a stirring dryer at 50° C., and in a stirring state at 60 rpm, the saturated ammonium sulfate solution prepared in step (1) in the stirring dryer is sprayed to make the aqueous solution of ammonium sulfate uniform Coated on the surface of urea granules (with a particle size of 3-4mm), the spraying speed of the ammonium sulfate aqueous solution should be such that the surface of the urea is wet but does not produce water accumulation; Sieve to obtain ammonium sulfate-coated urea nitrogen fertilizer with urea as the inner core and an ammonium sulfate layer outside the inner core.

[0059] The ammonium sulfate-coated urea nitrogen fertilizer prepared in this example is suitable as a base fertilizer and suitable for loam soil; suitable crops include winter wheat, summer corn, vegetables, fruit trees, vegetables and ot...

Embodiment 3

[0064] (1) 15 parts of ammonium sulfate are mixed with water to obtain a saturated solution of ammonium sulfate;

[0065] (2) 85 parts of urea granules are placed in a stirring dryer at 70° C., and in a stirring state at 60 rpm, the saturated ammonium sulfate solution prepared in step (1) in the stirring dryer is sprayed to make the aqueous solution of ammonium sulfate uniform Coated on the surface of urea granules (with a particle size of 3-4mm), the spraying speed of the ammonium sulfate aqueous solution should be such that the surface of the urea is wet but does not produce water accumulation; Sieve to obtain ammonium sulfate-coated urea nitrogen fertilizer with urea as the inner core and an ammonium sulfate layer outside the inner core.

[0066] The ammonium sulfate-coated urea nitrogen fertilizer prepared in this example is suitable as a base fertilizer, and is suitable for sandy loam soil. In sandy loam soil, it is better to apply 10-15 cm into the soil. Suitable crops ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com