Fiber reinforced thermal insulation concrete wall body

A thermal insulation concrete and fiber reinforced technology, applied in the field of fiber reinforced thermal insulation concrete walls, can solve problems such as damage and micro-cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

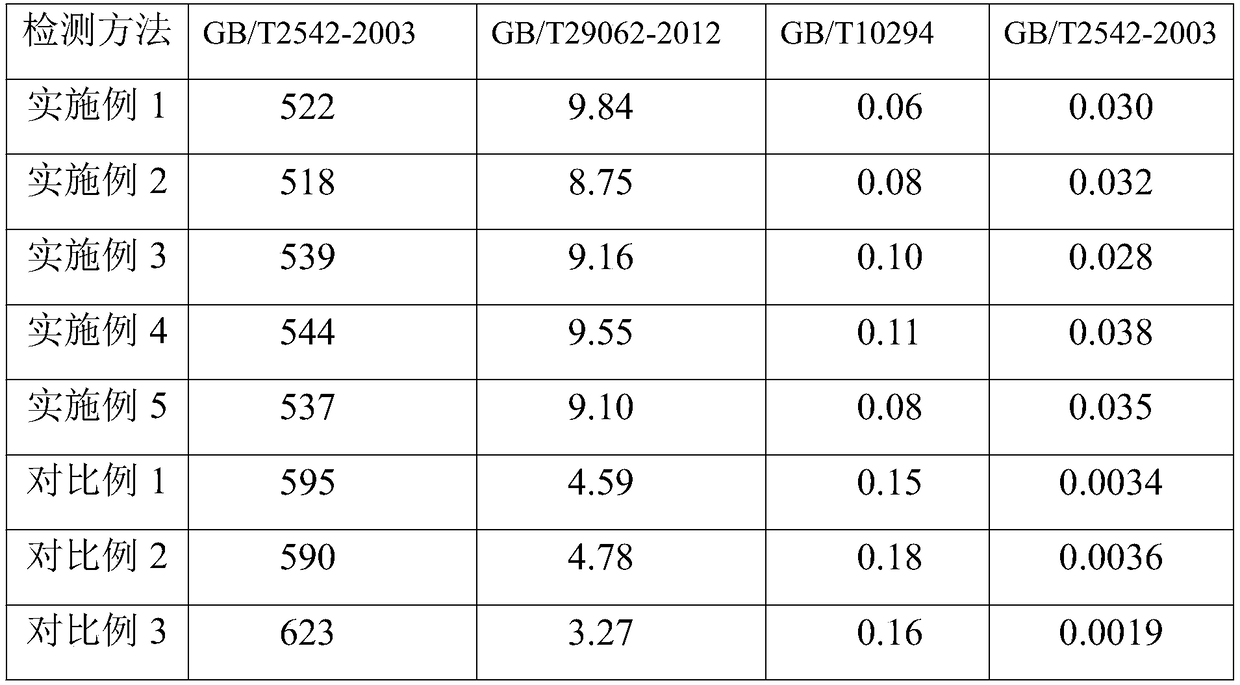

Examples

preparation example Construction

[0019] The present invention also provides a method for preparing the fiber-reinforced thermal insulation concrete wall, comprising the following steps:

[0020] (1) Spinning after mixing the first polymer emulsion and the second blowing agent uniformly to obtain polymer fibers; then placing the polymer fibers, chain extenders and metal oxide powders in the second polymer emulsion, React at 60-100°C for 15-60 minutes, then soak in acidic solution to obtain composite porous fibers;

[0021] (2) Mix fly ash, cement, fine sand, diatomaceous earth, light calcium carbonate, light aggregate, composite porous fiber and waste rubber under mechanical stirring conditions to obtain a powder mixture;

[0022] (3) After uniformly dispersing the water reducer and other additives in water, add them to the above powder mixture, and continue to stir for 60-150s to obtain a mixed slurry; finally, add the first foaming agent to the mixed slurry, and stir evenly to obtain Concrete precursor;

...

Embodiment 1

[0029] (1) Spin after mixing 24kg polyethylene terephthalate emulsion and 6kg 4,4-oxobisbenzenesulfonyl hydrazide evenly to obtain polyethylene terephthalate fibers, and the spinning process is: The power supply voltage is 30kV, the spinning temperature is 25°C, and the relative humidity is 60%; the needle spacing of the multi-needle spinneret unit is 25cm, and the number of spinneret unit needleheads is 60; 22kg polyethylene terephthalate fiber, 20kg ethylene glycol and Put 1.2kg of zinc nitrate in 12kg of polyethylene terephthalate emulsion, react at 80°C for 45 minutes to obtain polymer fibers, then soak the polymer fibers in a hydrochloric acid solution with a pH of 3 for 2 hours, and replace them every 15 minutes A hydrochloric acid solution to obtain a composite porous fiber;

[0030] Soak 4kg of waste rubber granules in an acidic solution with a pH of 6-6.5 for 4 hours to obtain acidified rubber, mix the acidified rubber and 10kg of maleic anhydride in water evenly, and...

Embodiment 2

[0035] (1) 20kg of nylon 6 emulsion and 2kg of 4,4-oxobisbenzenesulfonyl hydrazide are mixed evenly and then spun to obtain nylon 6 fiber. The spinning process is: power supply voltage 30kV, spinning temperature 25°C, relative The humidity is 60%; the distance between the needles of the multi-needle spinning unit is 25cm, and the number of needles in the spinning unit is 60; 18kg of nylon 6 fibers, 24kg of 1,3-butanediol and 2kg of zinc oxide are placed in 10kg of nylon 6 emulsion, at 80°C React at low temperature for 30 minutes to obtain polymer fibers, then soak the polymer fibers in a hydrochloric acid solution with a pH of 2 for 1.5 hours, wherein the hydrochloric acid solution is replaced every 15 minutes to obtain composite fibers B, and treat composite fibers B at 150°C for 30 minutes, composite porous fiber

[0036] Soak 3kg of waste rubber particles in an acidic solution with a pH of 6-6.5 for 3 hours to obtain acidified rubber, mix the acidified rubber and 9kg of mal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com