Sulphoaluminate self-fluorescent gelatinizing mineral and preparation method thereof

A technology of sulfoaluminate and autofluorescence, which is applied in the field of building decoration materials, can solve problems such as difficult control of light color, brightness and luminous time, adverse effects of gelling materials, unstable luminous performance, etc., and achieve long luminous time and improved Good burnability and frost resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

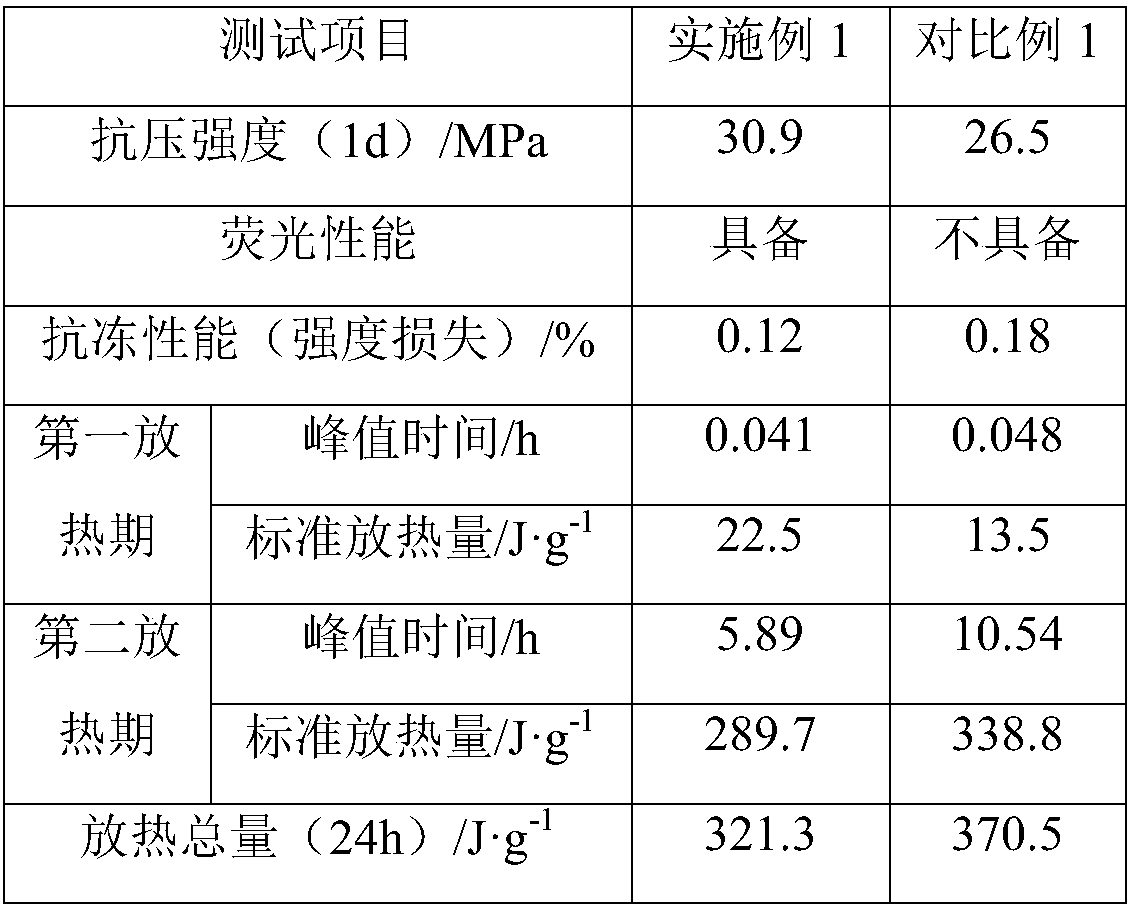

Embodiment 1

[0022] A sulfoaluminate self-fluorescent gelling mineral is prepared from the following raw materials in parts by weight: 25 parts of calcium carbonate, 30 parts of barium carbonate, 5 parts of barium sulfate, 55 parts of aluminum oxide, 25 parts of calcium sulfate dihydrate, 0.5 parts of rare earth element, 3 parts of high molecular polymer.

[0023] As mentioned, the rare earth element is Eu 2 o 3 .

[0024] Said high molecular polymer is polyurethane acrylate.

[0025] A preparation method of sulfoaluminate self-fluorescence gel mineral is prepared by the following steps:

[0026] 1) Grinding: Calcium carbonate, barium carbonate, barium sulfate, aluminum oxide, and calcium sulfate dihydrate are respectively ground and passed through a 200-mesh sieve;

[0027] 2) Mixing: Proportion the raw materials obtained in step 1 according to parts by weight, and dry mix them for 45 minutes under the condition of 60r / min to obtain the dry mix; use alcohol as the medium, mix the dry ...

Embodiment 2

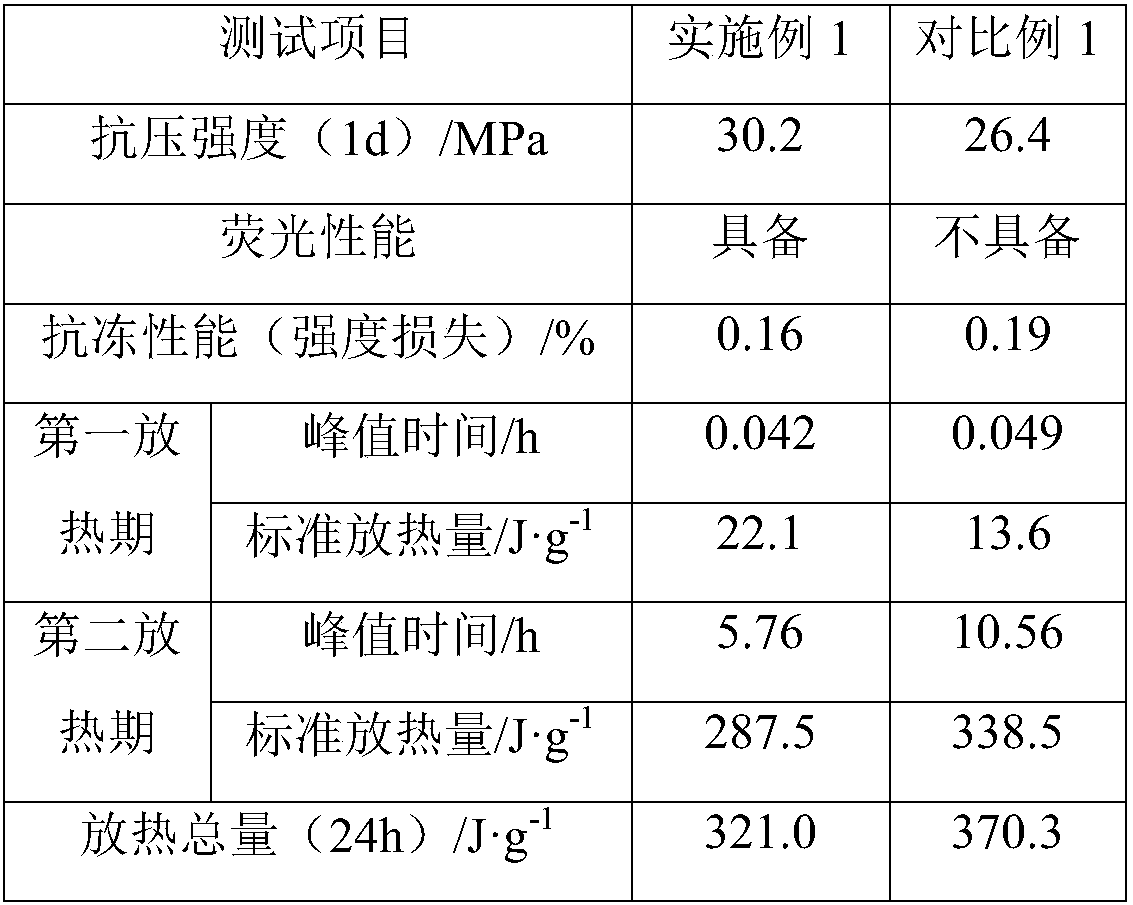

[0037] A sulfoaluminate self-fluorescent gelling mineral is prepared from the following raw materials in parts by weight: 27 parts of calcium carbonate, 28 parts of barium carbonate, 6 parts of barium sulfate, 54 parts of aluminum oxide, 26 parts of calcium sulfate dihydrate, 0.6 parts of rare earth elements, 2.5 parts of high molecular polymers.

[0038] As mentioned, the rare earth element is Tb 2 o 3 .

[0039] Said high molecular polymer is urethane acrylate.

[0040] A preparation method of sulfoaluminate self-fluorescence gel mineral is prepared by the following steps:

[0041] 1) Grinding: Calcium carbonate, barium carbonate, barium sulfate, aluminum oxide, and calcium sulfate dihydrate are respectively ground and passed through a 200-mesh sieve;

[0042] 2) Mixing: Proportioning the raw materials obtained in step 1 after grinding by weight, and dry mixing for 43 minutes under the condition of 65r / min to obtain the dry mixture; using alcohol as the medium, dry the m...

Embodiment 3

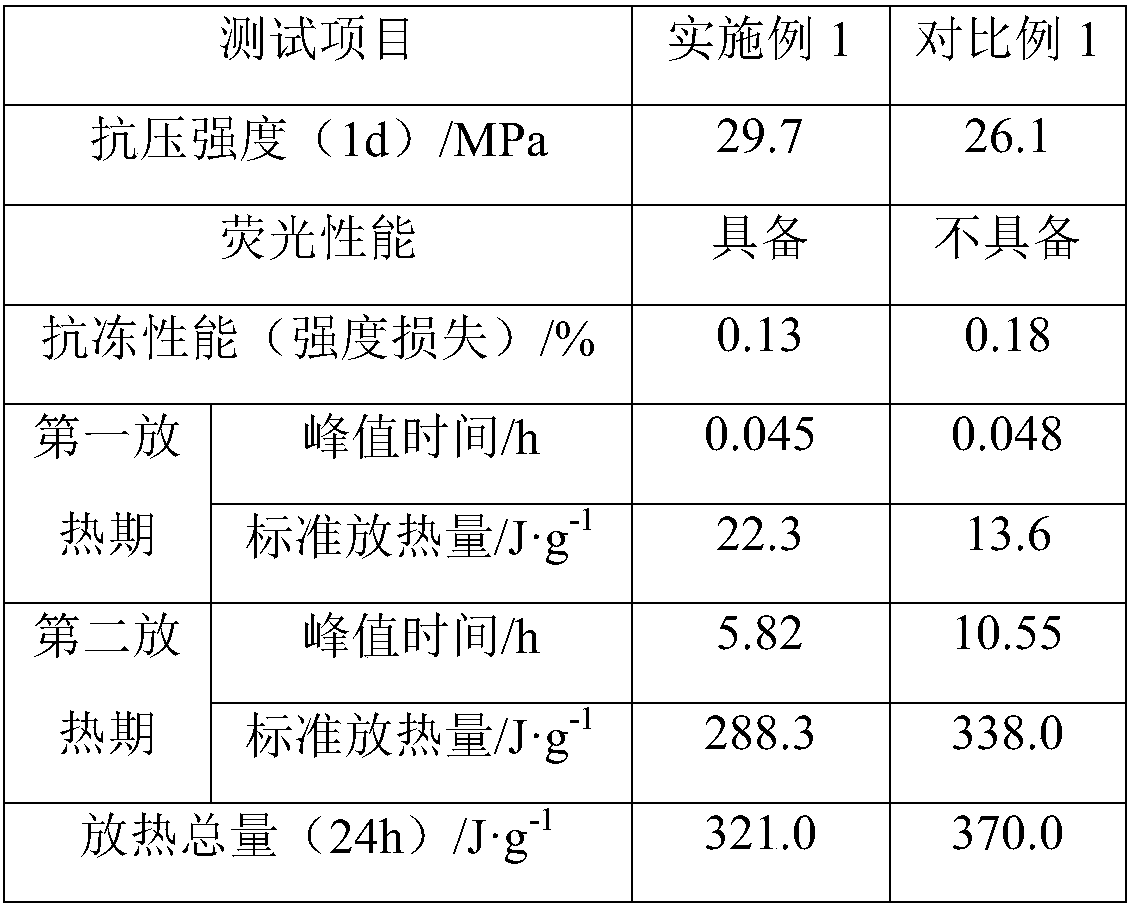

[0052] A sulfoaluminate self-fluorescence gelling mineral is prepared from the following raw materials in parts by weight: 28 parts of calcium carbonate, 26 parts of barium carbonate, 6 parts of barium sulfate, 52 parts of aluminum oxide, 28 parts of calcium sulfate dihydrate, 0.7 parts of rare earth elements, 2.5 parts of high molecular polymers.

[0053] As mentioned, the rare earth element is Dy 2 o 3 .

[0054] Said high molecular polymer is polyurethane acrylate.

[0055] A preparation method of sulfoaluminate self-fluorescence gel mineral is prepared by the following steps:

[0056] 1) Grinding: Calcium carbonate, barium carbonate, barium sulfate, aluminum oxide, and calcium sulfate dihydrate are respectively ground and passed through a 200-mesh sieve;

[0057] 2) Mixing: Proportioning the raw materials obtained in step 1 after grinding by weight, and dry mixing for 41 minutes under the condition of 65r / min to obtain the dry mixture; using alcohol as the medium, dry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com