Method for recycling hydrochloric acid in P204 ferric chloride solution

A technology for recovering hydrochloric acid and P204, which is applied in chemical instruments and methods, iron halide, chlorine/hydrogen chloride, etc., can solve problems such as increased pressure in wastewater treatment, poor on-site environment in pulping stations, equipment failures, etc., to reduce pressure and improve process flow Simple, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with specific examples.

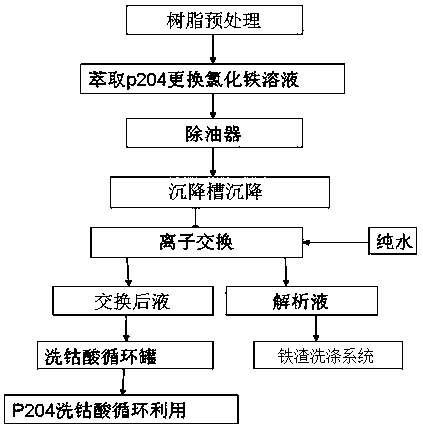

[0023] A method for reclaiming hydrochloric acid in a P204 ferric chloride solution, comprising the following steps:

[0024] A. Pretreat the SQD-74 resin, wash the SQD-74 resin with deionized water until the effluent is clear, transparent and colorless, and then put the SQD-74 resin into the ion exchange column.

[0025] B. Replace the ferric chloride solution in the iron washing section from 6mol / l to 4.5mol / l in the P204 extraction and impurity removal process. The average impurity content of the replaced ferric chloride solution is Co1.35g / l, Mn12.98g / l l, Cu3.99g / l, Fe0.21g / l, Zn1.23g / l, H + 4.9mol / l, the replaced ferric chloride solution enters the degreaser for filtration treatment, removes the suspended matter and oil contained in the ferric chloride solution, and the treated ferric chloride solution enters the primary settling tank and the secondary settling tank, S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com