Semi-sliding box-type buttress of floating production storage and offloading (FPSO) upper module

A sliding and box-type technology, which is applied to ship components, ships, dry docks, etc., can solve problems such as structural instability, pipeline tearing, deformation or tearing, and achieve improved resistance to deformation, stability and life. , the effect of improving the strength of the pier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

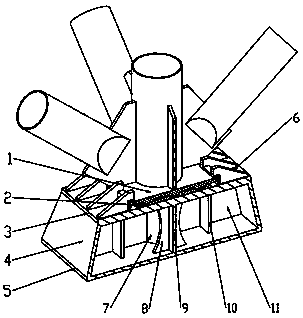

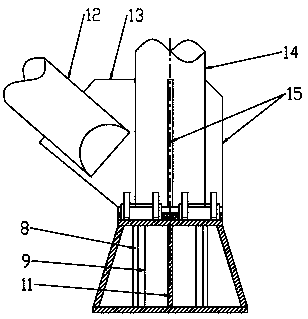

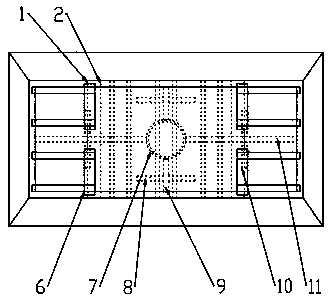

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention is a semi-sliding FPSO upper module box-type pier, and the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a semi-sliding FPSO upper module box-type pier of the present invention is mainly composed of a sliding trapezoidal tooth backing plate 1, a sliding trapezoidal groove backing plate 2, a box cover plate 3, a box side support plate 4, and a box body Bottom backing plate 5, baffle plate 6, supporting circular column 7, concave arc bracket 8, longitudinal side wing support plate 9, rectangular bracket 10, transverse side wing support plate 11, inclined support pipe 12, inclined pipe column bracket 13, Module main support tube 14, riser sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com