A preparation method of a subway vehicle optical fiber early warning pantograph carbon slide plate

A pantograph carbon skateboard and carbon skateboard technology, which is applied to vehicle components, current collectors, electric vehicles, etc., can solve the problems of serious wear of catenary wires, inability to meet the requirements of locomotives for skateboards, and high cost, and achieve a good safety early warning effect. Effect

Active Publication Date: 2019-10-01

DATONG XINCHENG NEW MATERIAL CO LTD

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Among them, the powder metallurgy sliding board has high mechanical strength, good impact resistance, good electrical conductivity and wear resistance, but it wears more seriously on the catenary wire; the carbon sliding board itself is a good lubricant, self-lubricating performance and lightening Good grinding performance, less wear on catenary wires, and high temperature resistance, not easy to weld with catenary wires, but its mechanical strength is low and impact resistance is poor, so it is easy to break or crack; metal-impregnated carbon slides have both powder metallurgy The skateboard has the characteristics of high mechanical strength and low resistivity, and has the advantage of less wear and tear on the wires of the pure carbon skateboard. It needs to be reshaped 1~2 times to ensure the surface of the skateboard is smooth, and it is expensive

With the development of high-speed electric locomotives, these types of skateboards cannot meet the requirements of locomotives for skateboards.

At present, the material of foreign skateboards is mainly metal-impregnated carbon skateboards, which have superior performance, but there is no description of specific preparation methods in the literature, and the price is expensive.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

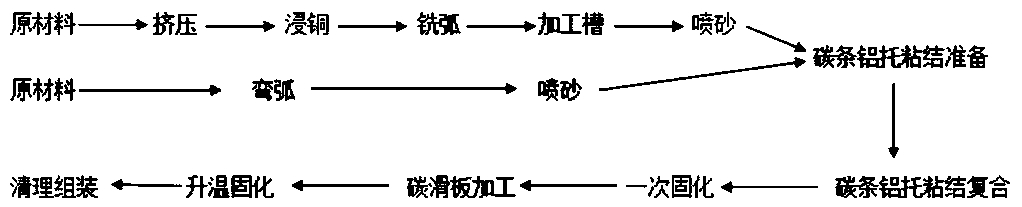

The invention discloses a method for preparing a metro vehicle optical fiber pre-warning pantograph carbon sliding plate. The method comprises a preparation technology for carbon strip production andprocessing, a preparation technology for aluminum support production and processing, and a preparation technology for optical fiber pre-warning pantograph carbon sliding plate production and processing. The sliding plate is low in electrical resistivity, and friction performance, abrasion resistance, impact toughness and other properties of the sliding plate are also better than those of pantograph sliding plates which are currently used, early prevention is well achieved, danger is avoided, processing is carried out in advance, and timely replacement is achieved. The method can be used for processing the metro vehicle optical fiber pre-warning pantograph carbon sliding plate, and can realize processing under the condition of an existing technology; the original processing precision and duration are guaranteed under the condition that a structure is additionally arranged, and the processing difficulty of other parts is not affected.

Description

technical field The invention relates to the technical field of carbon skateboards, in particular to a method for preparing a carbon skateboard for an optical fiber early warning pantograph of a subway vehicle. Background technique With the development of the national economy and the development of the transportation market, corresponding scientific research and development are also being carried out, among which improving the safety of electric locomotive operation is the key research direction. The pantograph carbon skateboard is the soul part of the electric locomotive, which transmits the current on the transmission grid to the locomotive power supply system to maintain the normal operation of the electric locomotive. Therefore, the quality of the skateboard has a very important impact on the locomotive. It is required that it must be safe in use. It can not only wear less on the catenary wire, but also have sufficient service life without affecting the pantograph-catena...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B60L5/20C04B37/02

Inventor 李江

Owner DATONG XINCHENG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com