Impulse type mist spraying cooling device and impulse control method

A spray cooling and pulse type technology, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems of influence, decrease of droplet crossing speed, strengthen the convection effect of liquid film on the heating surface, etc., and achieve the reduction of thermal resistance, High utilization rate and the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

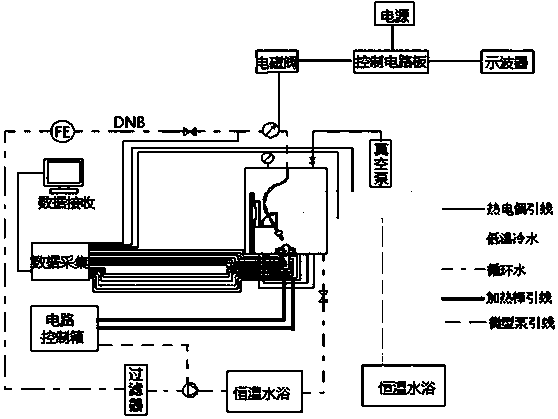

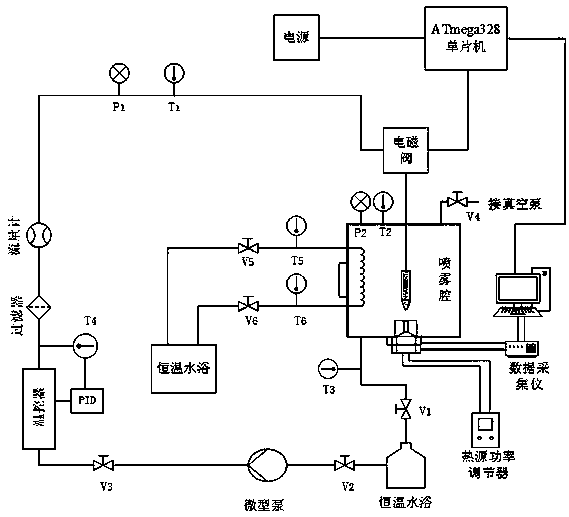

[0015] Such as figure 1 The schematic diagram of the structure of the pulse spray cooling device is shown. The pulse spray cooling device mainly includes four parts: data acquisition part, control part, circulating water part and injection part.

[0016] The data acquisition section includes data acquisition instruments and computers; the control section includes solenoid valves, circuit control boxes and water pumps; the circulating water section mainly includes two constant temperature water baths, pipelines and filters; the injection section includes nozzles, jet pumps, injection brackets, and vacuum pumps and a simulated heat source.

[0017] The vacuum pump is used to absorb the air in the closed chamber, so that each experiment can be carried out under vacuum conditions, reducing the interference of the external environment. The first constant temperature water bath introduces low-temperature cold water to maintain the ambient temperature of the chamber at a lower level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com