Preparation and application of magnetic dual-network kation hydrogel-based composite adsorbing material

A cationic hydrogel and composite adsorption material technology, which is applied in the fields of adsorbing water/sewage treatment, water pollutants, alkali metal compounds, etc., can solve the problem of unreported inorganic anions in water, etc. The effect of electric charge, strong exclusive adsorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

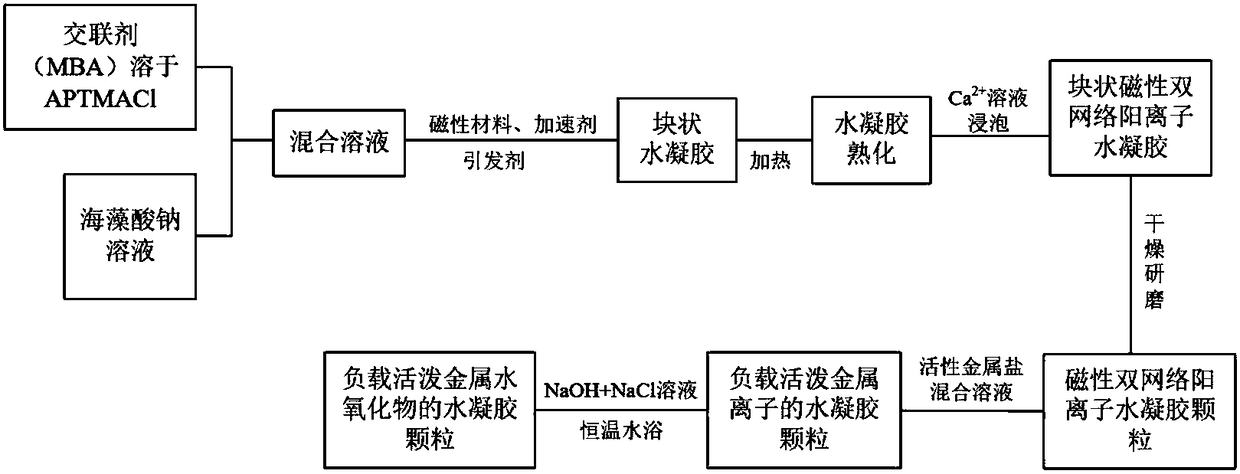

Method used

Image

Examples

Embodiment example 1

[0036] 1. Weigh 5g of (3-acrylamidopropyl)trimethylammonium chloride (APTMACl) monomer, and add 0.5g of cross-linking agent N,N'-methylenebisacrylamide (MBA) into it. Weigh 0.5g of sodium alginate and add it to 10ml of water. After the cross-linking agent MBA and sodium alginate are completely dissolved, mix the two solutions and add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 . After the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of the initiator, and stir and react in a 60°C water bath for 15min. After the gel was formed, the resulting magnetic hydrogel was transferred to a glass bottle and immersed in a calcium chloride solution for 2 days. Then soak in deionized water for 3 days, and change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into ...

Embodiment example 2

[0040] 1. Weigh 5g of (3-acrylamidopropyl)trimethylammonium chloride (APTMACl) monomer, and add 0.5g of cross-linking agent N,N'-methylenebisacrylamide (MBA) into it. Weigh 0.5g of sodium alginate and add it to 10ml of water. After the cross-linking agent MBA and sodium alginate are completely dissolved, mix the two solutions and add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 . After the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of the initiator, and stir and react in a 60°C water bath for 15min. After the gel was formed, the resulting magnetic hydrogel was transferred to a glass bottle and immersed in a calcium chloride solution for 2 days. Then soak in deionized water for 3 days, and change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into ...

Embodiment example 3

[0044] 1. Weigh 5g of (3-acrylamidopropyl)trimethylammonium chloride (APTMACl) monomer, and add 0.5g of cross-linking agent N,N'-methylenebisacrylamide (MBA) into it. Weigh 0.5g of sodium alginate and add it to 10ml of water. After the cross-linking agent MBA and sodium alginate are completely dissolved, mix the two solutions and add 0.1ml accelerator N,N,N',N'-tetramethylethylenediamine (TEMED) and 0.5g magnetic γ-Fe 2 o 3 . After the above substances are mixed evenly, add 1.5mL saturated potassium persulfate (KPS) solution of the initiator, and stir and react in a 60°C water bath for 15min. After the gel was formed, the resulting magnetic hydrogel was transferred to a glass bottle and immersed in a calcium chloride solution for 2 days. Then soak in deionized water for 3 days, and change the water every 8 hours to wash away unreacted substances such as monomers, cross-linking agents, initiators and accelerators. The magnetic hydrogel is then freeze-dried and ground into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com