Machine tool for processing wafer surface

A technology of surface processing and machine tools, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., and can solve problems such as unfavorable popularization, damage to wafers loaded, and reduced production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

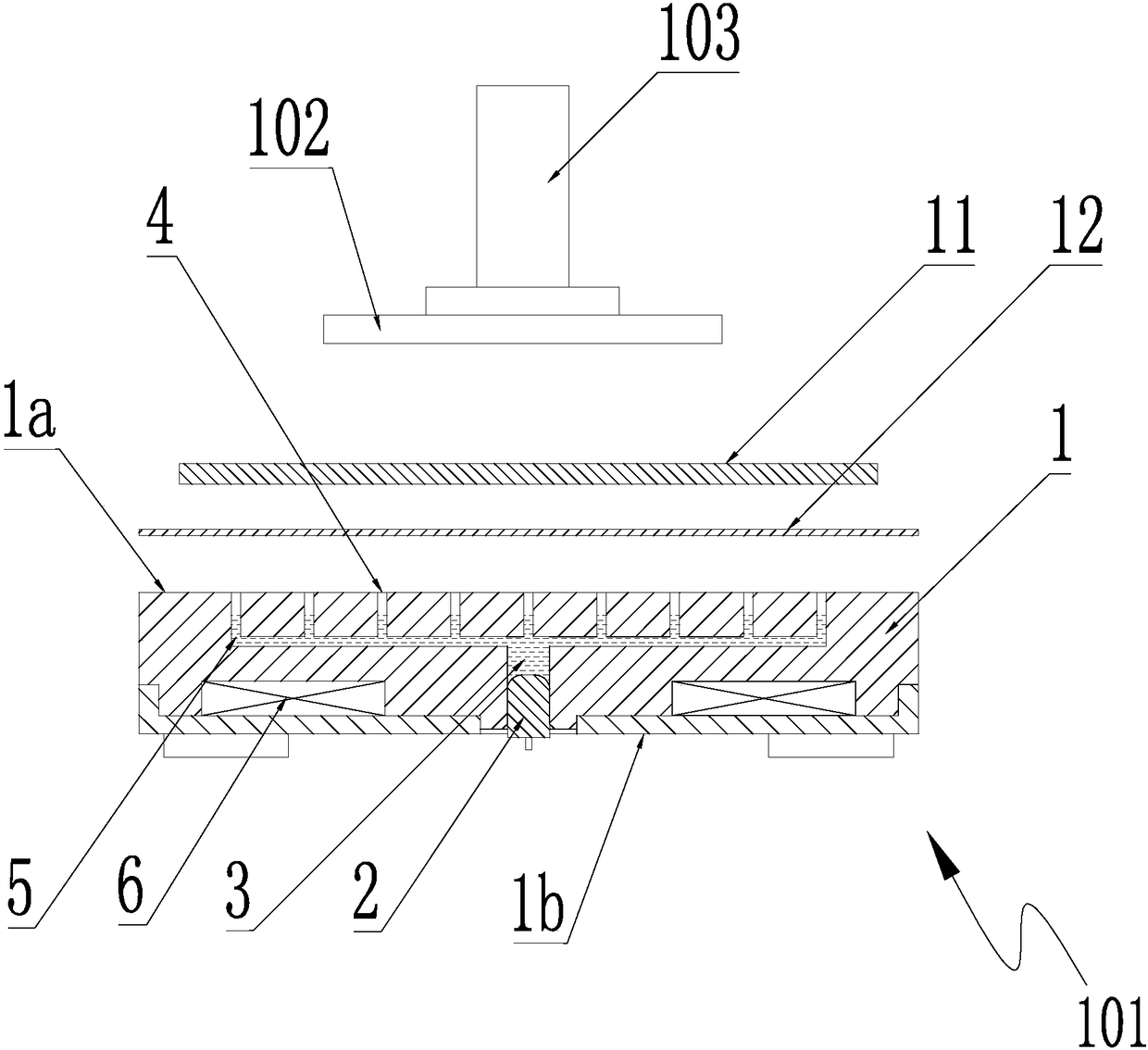

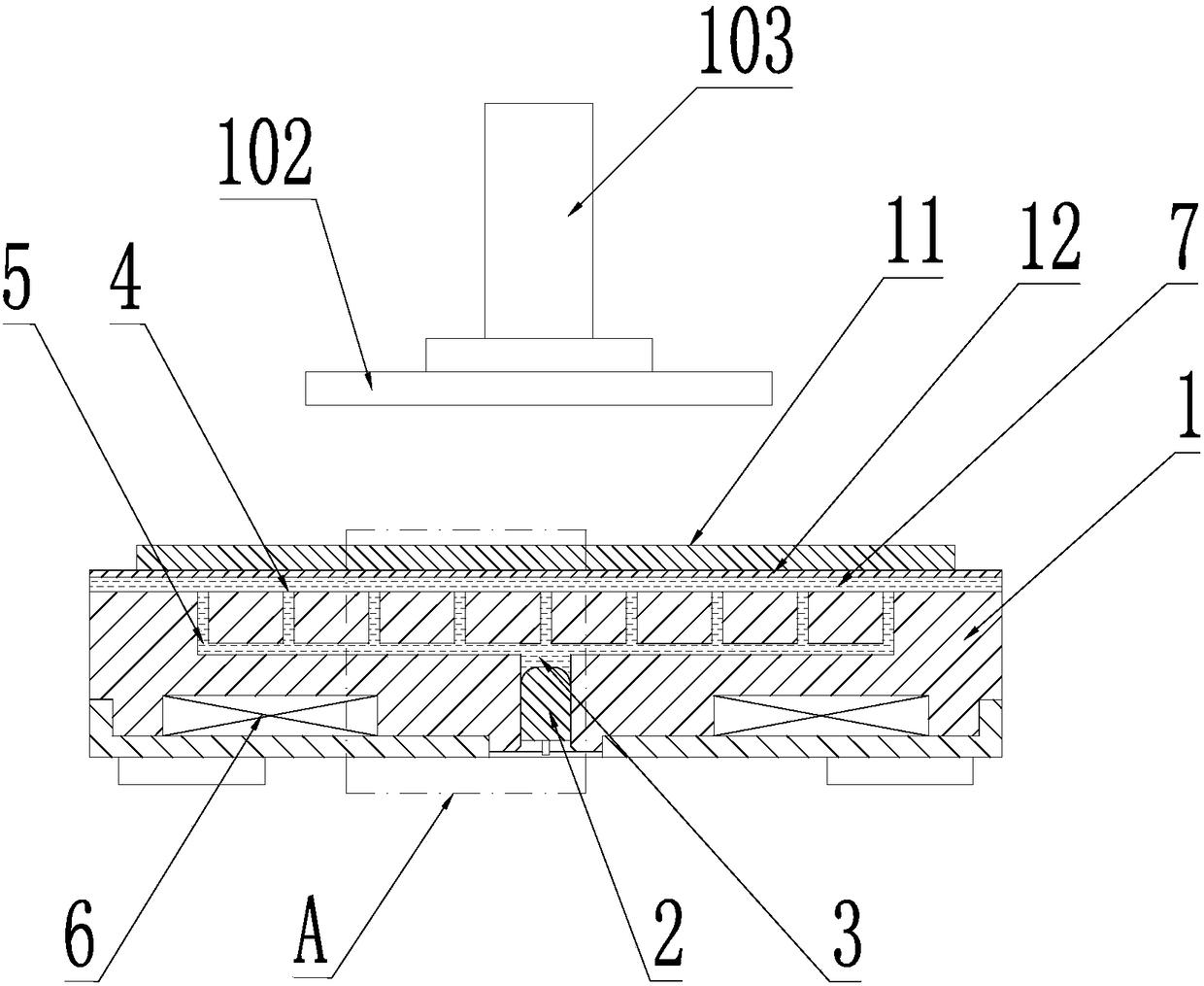

Image

Examples

Embodiment 1

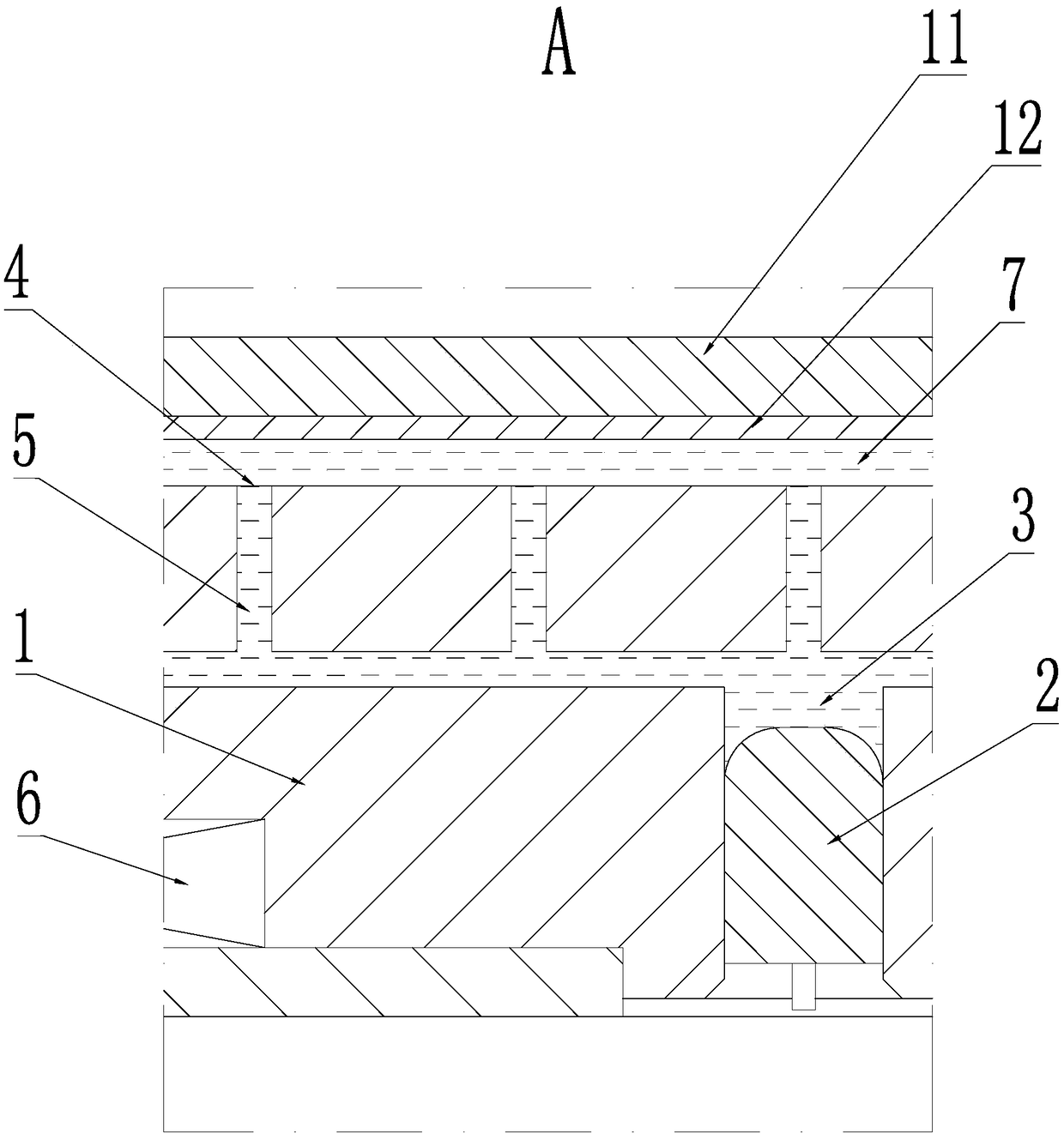

[0035] As a preference, the above-mentioned plug 2 is provided with a slot 2.1, a connecting pipe 2.2 and a pressure relief pipe 2.3, the upper end of the connecting pipe 2.2 communicates with the liquid storage chamber 3, and the lower end of the pressure relief pipe 2.3 runs through the plug 2 The lower end surface of the connecting pipe 2.2 communicates with the space outside the base body 1, the lower end of the connecting pipe 2.2 and the upper end of the pressure relief pipe 2.3 communicate with the slot 2.1, and a valve plate 8 is arranged in the slot 2.1, and the valve plate 8 Move along the groove depth direction of the slot 2.1 to make the connecting pipe 2.2 communicate with or disconnect from the pressure relief pipe 2.3. As shown in the figure, the above-mentioned groove depth direction is the vertical direction shown in the figure, and it is also the length direction of the plug 2 or the thickness direction of the base body 1 .

Embodiment 2

[0037] The general structure is the same as that of Embodiment 1, the difference is that the lower end of the connecting pipe 2.2 communicates with the groove bottom of the slot 2.1 along the length direction of the plug 2, and the upper end of the pressure relief pipe 2.3 connects with the bottom of the slot 2.1 along the horizontal direction. The side wall communicates with the position close to the groove bottom.

Embodiment 3

[0039] The general structure is the same as that of the second embodiment, except that the bottom of the slot 2.1 is inscribed upward along the length direction of the plug 2 to form an annular groove 2.4. The setting of the annular groove 2.4 can make air remain in the annular groove 2.4, and the compressibility of the air is used to make the load force of the valve plate at the initial stage of pulling out small, which is convenient for the valve plate to be pulled out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com