Method for preparing borate ester from fatty aldehyde

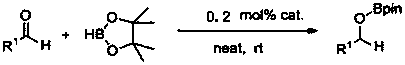

A technique for fatty aldehydes and boronate esters, applied in the field of preparing boronate esters, can solve the problems of weakening the nucleophilic addition activity of carbonyl, weakening the positive charge of carbonyl carbon, harsh reaction conditions, etc. The effect of adaptability and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

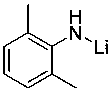

[0025] Example 1: 2,6-Dimethylanilinolithium catalyzed the borohydride reaction of cyclohexylbenzaldehyde and pinacol borane

[0026] In a dehydrated and deoxygenated reaction flask, add 40 ul of 2,6-dimethylanilinolithium in tetrahydrofuran (0.05M) (0.2 mol% amount) under the protection of argon, and then add 0.1596 mL of borane with a syringe. Mix well, then add 0.095 mL 2-pyridinecarboxaldehyde with a syringe. The mixture is stirred at room temperature. After 10 minutes of reaction, the NMR yield is 99%. After that, a small amount of tetrahydrofuran and excess borane are removed under reduced pressure to obtain the corresponding pinnacle. Alcohol borate C 6 H 5 COCH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). 1 H NMR (400 MHz, CDCl 3 ) δ 8.61 (d, J = 5.4 Hz, 1H, Ar-H), 7.91 (t, J = 7.7 Hz, 1H, Ar-H), 7.49-7.41 (m, 2H, Ar-H), 5.10 (s, 2H, OCH 2 ), 1.32 (s,12H, CH 3 ). 13 C NMR (101 MHz, CDCl 3 ) δ 159.82 (Ar-C), 143.72 (Ar-C), 139.56(Ar-C), 123.39 (Ar-C), 120.09 (Ar-C), 81.04 (OC), 66.47 (...

Embodiment 2

[0027] Example 2: 2,6-Dimethylanilinolithium catalyzed the borohydride reaction of propionaldehyde and pinacol borane

[0028] In a dehydrated and deoxygenated reaction flask, add 40 ul of 2,6-dimethylanilinolithium in tetrahydrofuran (0.05M) (0.2 mol% amount) under the protection of argon, and then add 0.1596 mL of borane with a syringe. Mix well, then add 0.072 mL propionaldehyde with a syringe. The mixture is stirred at room temperature. After 10 minutes of reaction, the NMR yield is 99%. After that, a small amount of tetrahydrofuran and excess borane are removed under reduced pressure to obtain the corresponding pinacol Borate CH 3 CH 2 COCH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). 1 H NMR (400 MHz, CDCl 3 ) δ 3.80 (t, J = 6.6 Hz, 2H, OCH 2 ), 1.63-1.54(m, 2H, CH 2 ), 1.25 (s, 12H, CH 3 ), 0.91 (t, J = 7.4 Hz, 3H, CH 3 ). 13 C NMR (101MHz, CDCl 3 ) δ 82.04 (OC), 66.02 (OCH 2 ), 24.14 (CH 3 CH 2 ), 24.05 (CH 3 ), 9.55(CH 2 CH 3 ).

[0029] Substituting lithium 2,6-dimethylanilinide wit...

Embodiment 3

[0031] Example 3: 2,6-Dimethylanilinolithium catalyzes the borohydride reaction of n-heptanal and pinacol borane

[0032] In the reaction flask after dehydration and deoxygenation, add 40ul 2,6-dimethylanilinide lithium tetrahydrofuran solution (0.05M) (0.2 mol% amount) under the protection of argon, then add 0.1596 mL borane with a syringe, and mix well Then add 0.1392 mL n-heptanal with a syringe. The mixture is stirred at room temperature. After 10 minutes of reaction, the NMR yield is 99%. Then, a small amount of tetrahydrofuran and excess borane are removed under reduced pressure to obtain the corresponding pinacol boron. Ester C 6 H 13 COCH 2 OB(OC(CH 3 ) 2 C(CH 3 ) 2 O). 1 H NMR (400 MHz, CDCl 3 ) δ 3.82 (t, J = 8 Hz, 2H, OCH 2 ), 1.52-1.58 (m,2H, CH 2 ), 1.27-1.34 (m, 8H, CH 2 ), 1.24 (s, 12H, CH 3 ), 0.87 (t, J = 8 Hz, 3H,CH 3 ). 13 C NMR (100 MHz, CDCl 3 ) δ 82.02 (OC), 64.40 (OCH 2 ), 31.29 (CH 2 ), 30.92(CH 2 ), 28.44 (CH 2 ), 25.02 (CH 2 ), 24.00 (CH 3 ), 22.05 (CH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com