Perfluoro sodium polymer electrolyte, preparation method and application of perfluoro sodium polymer electrolyte, all-solid-state sodium-ion battery and friction nano-generator system

A polymer and electrolyte technology, applied in the field of sodium-ion batteries, can solve the problems of inability to provide stable power output, flammability, low safety, etc., and achieve high efficiency and stable power output, long service life, and broad market prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0072] Preparation Example 1: Preparation of P2-type Na 0.67 Ni 0.23 Mg 0.1 mn 0.67 o 2

[0073] The molar ratio of ethylenediaminetetraacetic acid (EDTA), citric acid and total metal ions is 1:1.5:1. Dissolve stoichiometric EDTA in NH 3 ·H 2 O, and heated and stirred at 40 °C, and then the calculated amount of NaNO 3 added to the above solution. When NaNO 3 After complete dissolution, the calculated amount of Mn(NO 3 ) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2O was dissolved in the above solution. After heating and stirring for 10min, the calculated amount of citric acid was added, and the process of adding citric acid was controlled (using NH 3 ·H 2 O adjustment) has a pH of about 6. The solution was then stirred at 70°C until a gel was formed, and then dried at 120°C for 24h. Finally, the obtained precursor was calcined in air at 900 °C for 15 h to obtain the final product. spare.

preparation example 2

[0074] Preparation Example 2: Preparation of P2-type Na 0.67 Ni 0.42 Mg 0.2 mn 0.38 o 2

[0075] This preparation example adopts the method similar to preparation example 1 to carry out, the difference is, the Mn(NO 3 ) 2 4H 2 O, Ni(NO 3 ) 2 ·6H 2 O and Mg(NO 3 ) 2 ·6H 2 The amount of O is different from that in Preparation 1, but according to the P2-type Na of this preparation 0.67 Ni 0.42 Mg 0.2 mn 0.38 o 2 Quantitative relationships are added to the aforementioned substances. The rest are the same as in Preparation Example 1.

[0076] Get P2-type Na 0.67 Ni 0.42 Mg 0.2 mn 0.38 o 2 spare.

Embodiment 1

[0077] Embodiment 1: Preparation of PFSA-Na-1

[0078] The perfluorosulfonic acid resin (PFSA) was converted into PFSA-Na-1 by ion-exchange method in 1M NaOH aqueous solution at 80° C. for 12 h. Then, it was washed with deionized water and dried in an Ar atmosphere in a glove box at 25 °C.

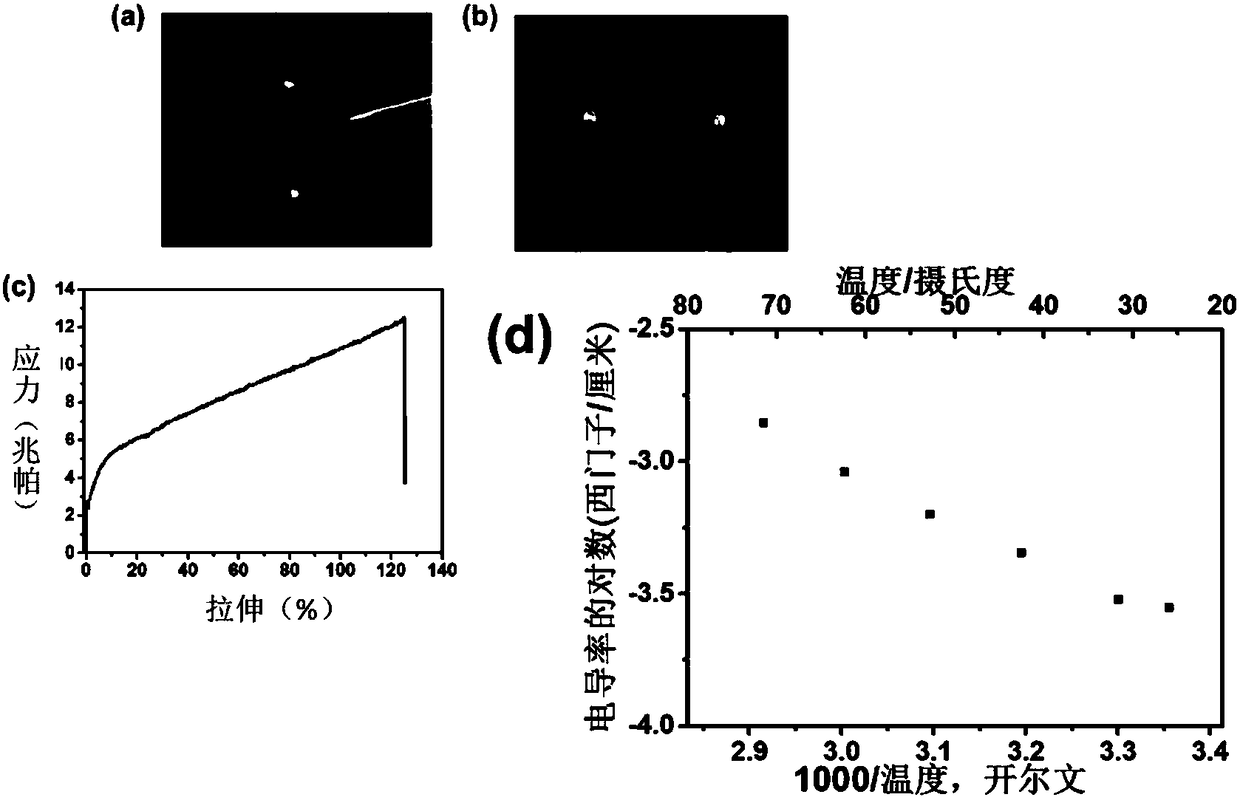

[0079] The flexible PFSA-Na-1 film prepared in this embodiment is as follows: figure 1 Shown in (a) and (b) in, wherein, (a) is the PFSA-Na-1 film in the folded state; (b) is the PFSA-Na-1 film in the restored state.

[0080] Adopt plastic film tensile property test method (GBT13022-1991) to test the stress-strain relation of the PFSA-Na-1 film that present embodiment prepares, obtain figure 1 Typical stress-strain relationship curve of PFSA-Na-1 film shown in (c).

[0081] Then soak the PFSA-Na-1 membrane in 60mL of EC-PC (v:v=1:1) mixed solvent, and the mixed solvent is contained in a 20g Store in an airtight container with active molecular sieves at 25°C for 48 hours.

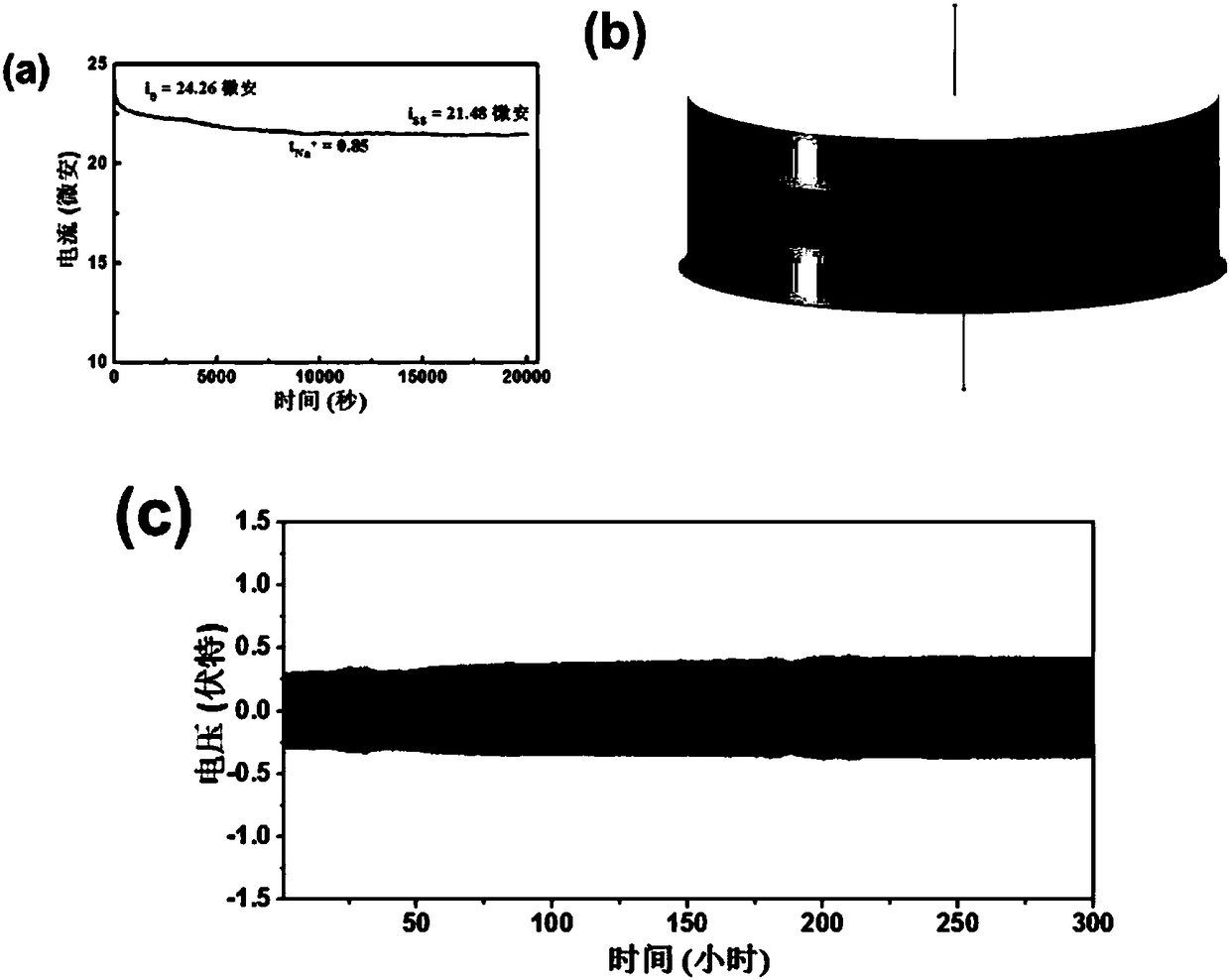

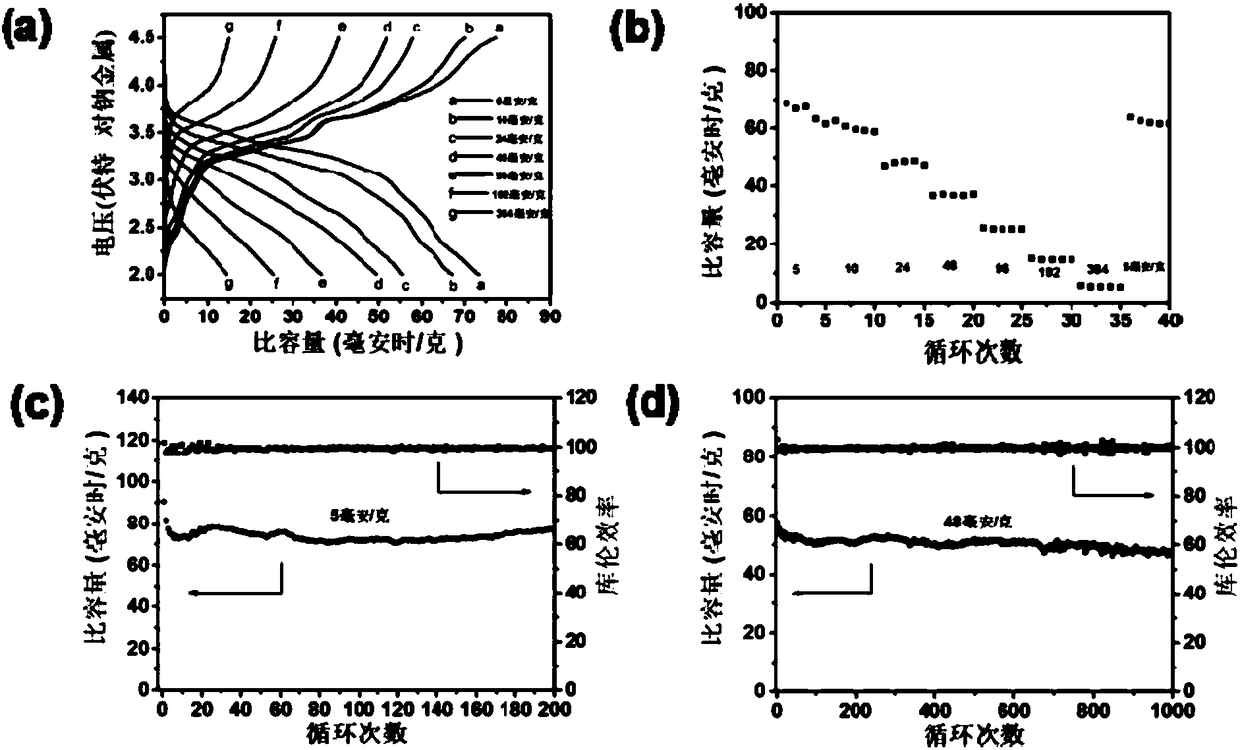

[0082] fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com