Preparation method of MnO2/CNT (carbon nanotube) composite electrode material

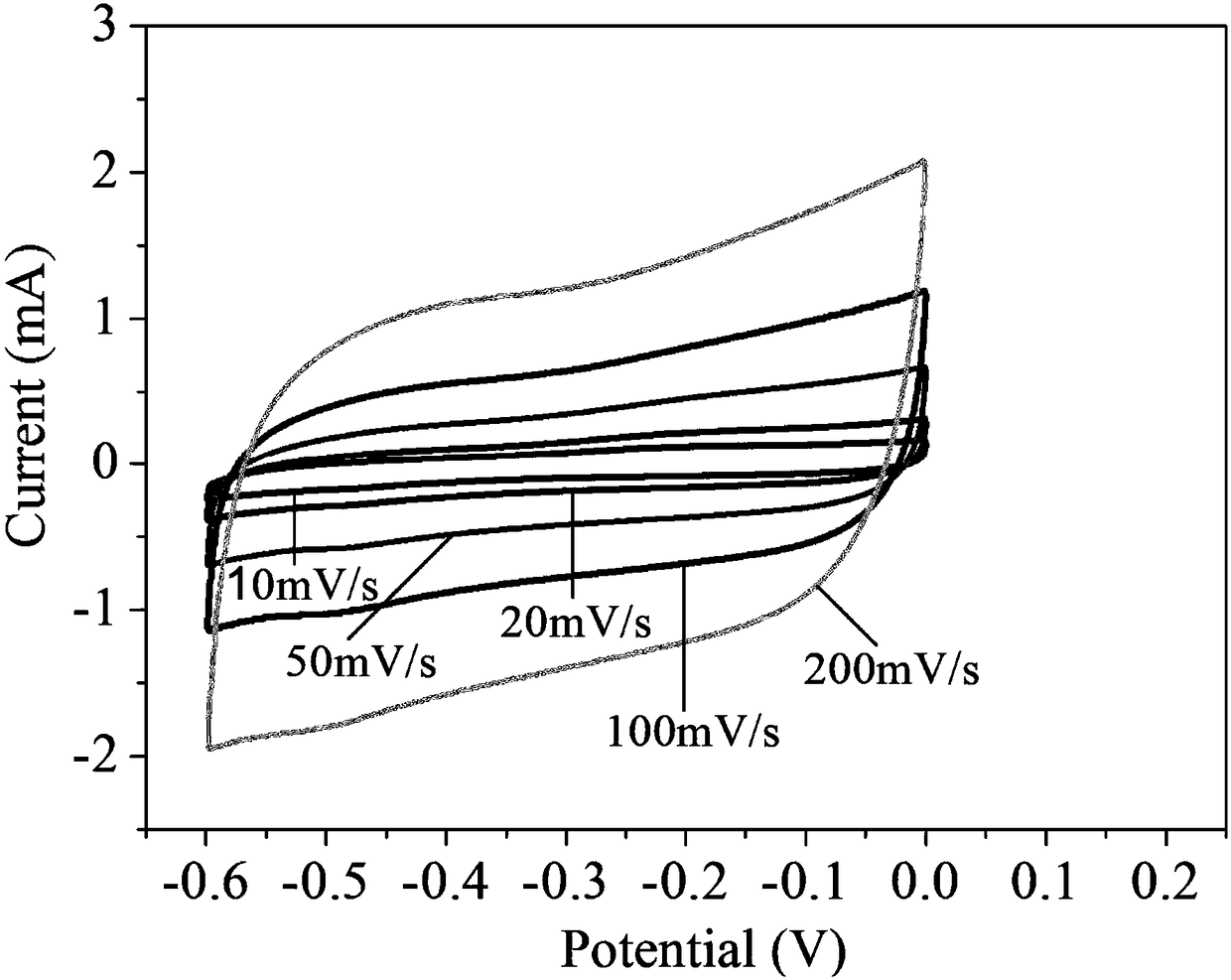

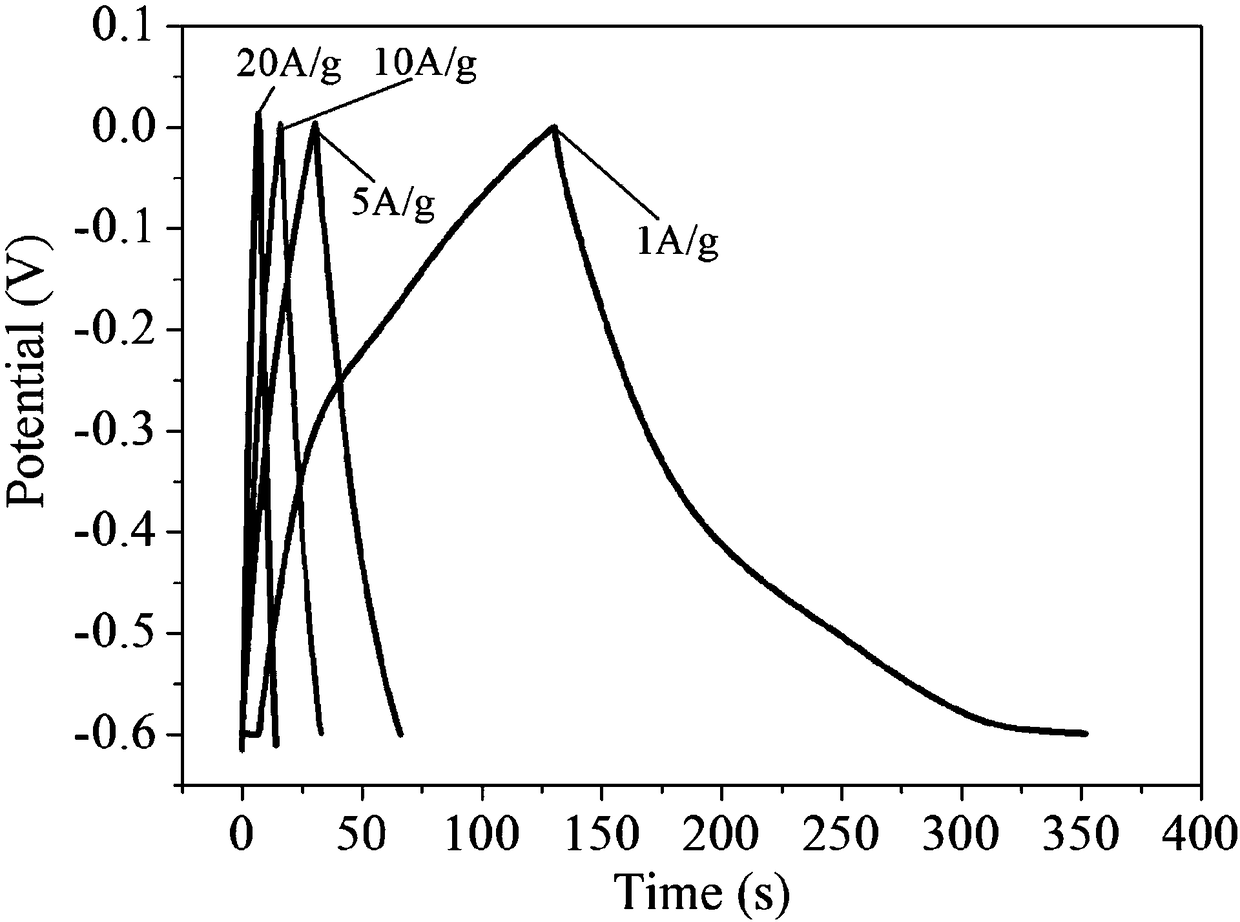

A technology of carbon nanotube composite and manganese dioxide, which is applied in the direction of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, etc., can solve the problems of preparing manganese dioxide/carbon nanotube composite materials that have not been seen, and achieve good electric current Effects of chemical reversibility, high specific capacity, conductivity, and electrochemical performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The specific preparation steps of manganese dioxide / carbon nanotube composite electrode material are as follows:

[0031] (1) Graphene growth on copper foil surface

[0032] Anodize a copper foil with a size of 1 cm × 2 cm in a phosphoric acid solution at a voltage of 10 V for 5 minutes, and perform ultrasonic cleaning with absolute ethanol and deionized water, and then place the cleaned copper foil in a quartz tube furnace; When the vacuum in the tube furnace is evacuated to below 15mTorr, the temperature of the tube furnace is raised to 1000°C, and then 300 sccm H 2 Heat-treat the copper foil for 10 minutes, and then pass 10sccm of CH 4 Grow graphene on copper foil for 15 minutes, and the graphene growth pressure is 350Torr;

[0033] (2) Carbon nanotube growth

[0034] Electron beam evaporation was used to deposit a 1nm iron catalyst layer and a 3nm aluminum oxide buffer layer on the surface of graphene grown on copper foil in sequence, and then the water-assisted ...

Embodiment 2

[0039] The specific preparation steps of manganese dioxide / carbon nanotube composite electrode material are as follows:

[0040] (1) Graphene growth on copper foil surface

[0041] Anodize a copper foil with a size of 1 cm × 2 cm in a phosphoric acid solution at a voltage of 10 V for 5 minutes, and perform ultrasonic cleaning with absolute ethanol and deionized water, and then place the cleaned copper foil in a quartz tube furnace; When the vacuum in the tube furnace is evacuated to below 15mTorr, the temperature of the tube furnace is raised to 1000°C, and then 300 sccm H 2 Heat-treat the copper foil for 10 minutes, and then pass 10sccm of CH 4Grow graphene on copper foil for 15 minutes, and the graphene growth pressure is 350Torr;

[0042] (2) Carbon nanotube growth

[0043] Electron beam evaporation was used to deposit a 1nm iron catalyst layer and a 3nm aluminum oxide buffer layer on the surface of graphene grown on copper foil in sequence, and then the water-assisted c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com