Electronic connecting wire with high thermal aging resistance and high toughness

An aging, high heat-resistant technology, used in circuits, insulated cables, electrical components, etc., can solve problems affecting the tensile, bending, electrical properties of electronic connecting wires, safety, low tensile yield strength and tensile strength, The lower cable sheath is prone to aging and other problems, and achieves the effects of good flame retardancy and electrical insulation continuous performance, long service life, and (thermal) aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

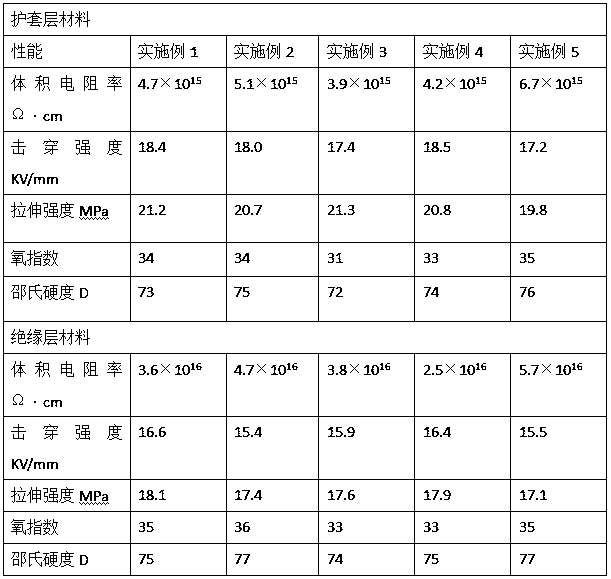

Embodiment 1

[0027] Embodiment 1: An electronic connecting wire with high heat aging resistance and toughness, which is composed of a conductor, an insulating layer coated on the outside of the conductor, and a sheath layer coated on the outside of the insulating layer; the sheath layer is composed of The raw material composition of following parts by weight: 35 parts of chloroprene rubber, 30 parts of polytetrafluoroethylene, 20 parts of maleic anhydride grafted polyethylene, 2 parts of asphalt, 0.8 part of dibasic calcium stearate, carboxymethyl fiber 0.3 parts of plain sodium, 1.2 parts of 2-hydroxy-4-methoxybenzophenone, 4 parts of titanium dioxide, 2 parts of polyadipate-1,4-butylene glycol ester diol, 1.5 parts of antimony pentoxide , 1 part of zinc oxide, 3 parts of crosslinking agent, and 1.5 parts of auxiliary crosslinking agent; the insulating layer is composed of the following raw materials in parts by weight: 40 parts of maleic anhydride grafted polyethylene, tetrafluoroethylene...

Embodiment 2

[0044]Embodiment 2: An electronic connection wire with high heat aging resistance and toughness, which is composed of a conductor, an insulating layer coated on the outside of the conductor, and a sheath layer coated on the outside of the insulating layer; the sheath layer is composed of The raw material composition of following parts by weight: 30 parts of chloroprene rubber, 35 parts of polytetrafluoroethylene, 18 parts of maleic anhydride grafted polyethylene, 2.5 parts of asphalt, 0.6 part of dibasic calcium stearate, carboxymethyl fiber 0.3 parts of plain sodium, 1 part of 2-hydroxy-4-methoxybenzophenone, 4.5 parts of titanium dioxide, 1.5 parts of polyadipate-1,4-butylene glycol ester diol, 1.8 parts of antimony pentoxide , 0.8 parts of zinc oxide, 3.5 parts of crosslinking agent, and 1.2 parts of auxiliary crosslinking agent; the insulating layer is composed of the following raw materials in parts by weight: 35 parts of maleic anhydride grafted polyethylene, tetrafluoroe...

Embodiment 3

[0061] Embodiment 3: An electronic connection wire with high heat aging resistance and toughness, which is composed of a conductor, an insulating layer coated on the outside of the conductor, and a sheath layer coated on the outside of the insulating layer; the sheath layer is composed of The raw material composition of following parts by weight: 25 parts of chloroprene rubber, 20 parts of polytetrafluoroethylene, 15 parts of maleic anhydride grafted polyethylene, 1 part of asphalt, 0.5 part of dibasic calcium stearate, carboxymethyl fiber 0.1 part of plain sodium, 0.8 part of 2-hydroxy-4-methoxybenzophenone, 3 parts of titanium dioxide, 1 part of polyadipate-1,4-butylene glycol ester diol, 1 part of antimony pentoxide , 0.5 parts of zinc oxide, 2 parts of crosslinking agent, and 1 part of auxiliary crosslinking agent; the insulating layer is composed of the following raw materials in parts by weight: 30 parts of maleic anhydride grafted polyethylene, tetrafluoroethylene-perflu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com