Organic vehicle for solar electronic paste and electronic paste containing same

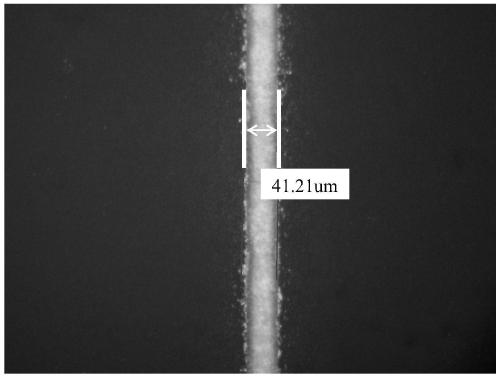

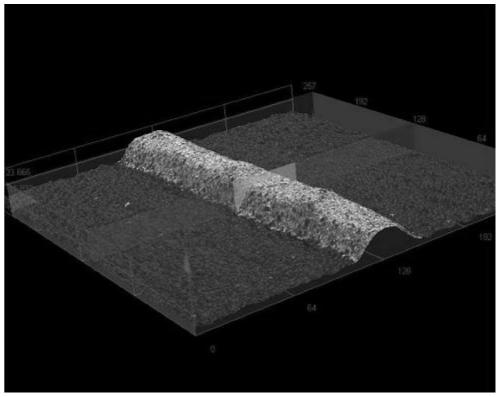

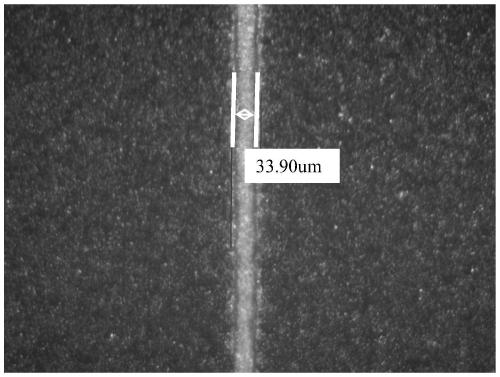

An organic carrier and electronic paste technology, applied in the field of solar photovoltaic, can solve the problems affecting the production of modules and the shutdown of manufacturers, and achieve the effects of eliminating solvent precipitation, regular printing lines, and high aspect ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] An organic vehicle for solar electronic paste, the organic vehicle comprises the following raw materials in parts by weight:

[0034] 20 parts of polymer carrier, 40 parts of solvent, 10 parts of netting agent, 5 parts of wetting agent, 10 parts of solid formulation, 10 parts of antioxidant, 5 parts of anti-orange peel agent;

[0035] The polymer carrier is ethylene glycol-cyclohexadiene polyether; the solvent is butyl carbitol; the netting agent is dodecane; the wetting agent is xylene; The formulation agent is paraffin; the antioxidant is 2,6-di-tert-butyl-4-methylphenol; the anti-orange peel agent is perfluoroalkyl ester compound FC-430;

[0036] The preparation method of the organic carrier is: weighing the polymer carrier, solvent, netting agent, wetting agent, solid-containing preparation agent, antioxidant, anti-orange peel agent in a container, and mechanically stirring and mixing; Put the roughly mixed organic carrier into an ultrasonic oscillator for ultrason...

Embodiment 2

[0041] An organic vehicle for solar electronic paste, the organic vehicle comprises the following raw materials in parts by weight:

[0042] 30 parts of polymer carrier, 35 parts of solvent, 10 parts of netting agent, 5 parts of wetting agent, 10 parts of solid formulation, 5 parts of antioxidant, 5 parts of anti-orange peel agent;

[0043] The polymer carrier is glycerol-cyclopentadiene polyether; the solvent is ethyl benzoate; the netting agent is cyclohexylbenzene; the wetting agent is cyclohexane; The formulation agent is paraffin; the antioxidant is 2,6-di-tert-butyl-4-methylphenol; the anti-orange peel agent is perfluoroalkylammonium sulfonate FC-120;

[0044] The preparation method of the organic carrier is: weighing the polymer carrier, solvent, netting agent, wetting agent, solid-containing preparation agent, antioxidant, anti-orange peel agent in a container, and mechanically stirring and mixing; Put the roughly mixed organic carrier into an ultrasonic oscillator fo...

Embodiment 3

[0049] An organic vehicle for solar electronic paste, the organic vehicle comprises the following raw materials in parts by weight:

[0050] 25 parts of polymer carrier, 35 parts of solvent, 10 parts of netting agent, 5 parts of wetting agent, 10 parts of solid formulation, 10 parts of antioxidant, 5 parts of anti-orange peel agent;

[0051] The polymer carrier is cyclohexyl alcohol-styrene polyether; the solvent is phenylethyl alcohol; the netting agent is cyclooctane; the wetting agent is toluene; the solid formulation agent is paraffin; The antioxidant is 2,6-di-tert-butyl-4-methylphenol; the anti-orange peel agent is perfluoroalkyl polyvinyl alcohol FC-171;

[0052] The preparation method of the organic carrier is: weighing the polymer carrier, solvent, netting agent, wetting agent, solid-containing preparation agent, antioxidant, anti-orange peel agent in a container, and mechanically stirring and mixing; Put the roughly mixed organic carrier into an ultrasonic oscillato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com